RAMTEQ ® n n n n

1 180-00411-01

2 180-00412-01

3 175-00001-05

4 170-00015-01

5 516-00001-01

6 190-00002-04

7 577-00002-01

8 140-00001-01

9 590-00003-01

10 180-00410-01

11 206-00050-02

12 210-00001-04

13 220-00015-02

14 230-00011-02

15 574-00002-01

16 250-00005-04

17 180-00430-01

18 180-00153-01

19 508-00002-01

20 155-00002-02

21 191-00006-01

22 180-00424-01

23 180-00423-01

24 180-00132-01

25 180-00133-01

26 191-00009-01

27 180-00425-01

28 185-00001-01

29 180-00413-01

30 180-00428-01

31 180-00418-01

32 180-00429-01

33 595-00038-01

34 180-00426-01

35 171-00001-01

36 567-00001-01

NOT SHOWN

439-00003-12

439-00003-13

457-00002-01

591-00001-02

270-00001-01

270-00001-02

270-00001-03

270-00001-04

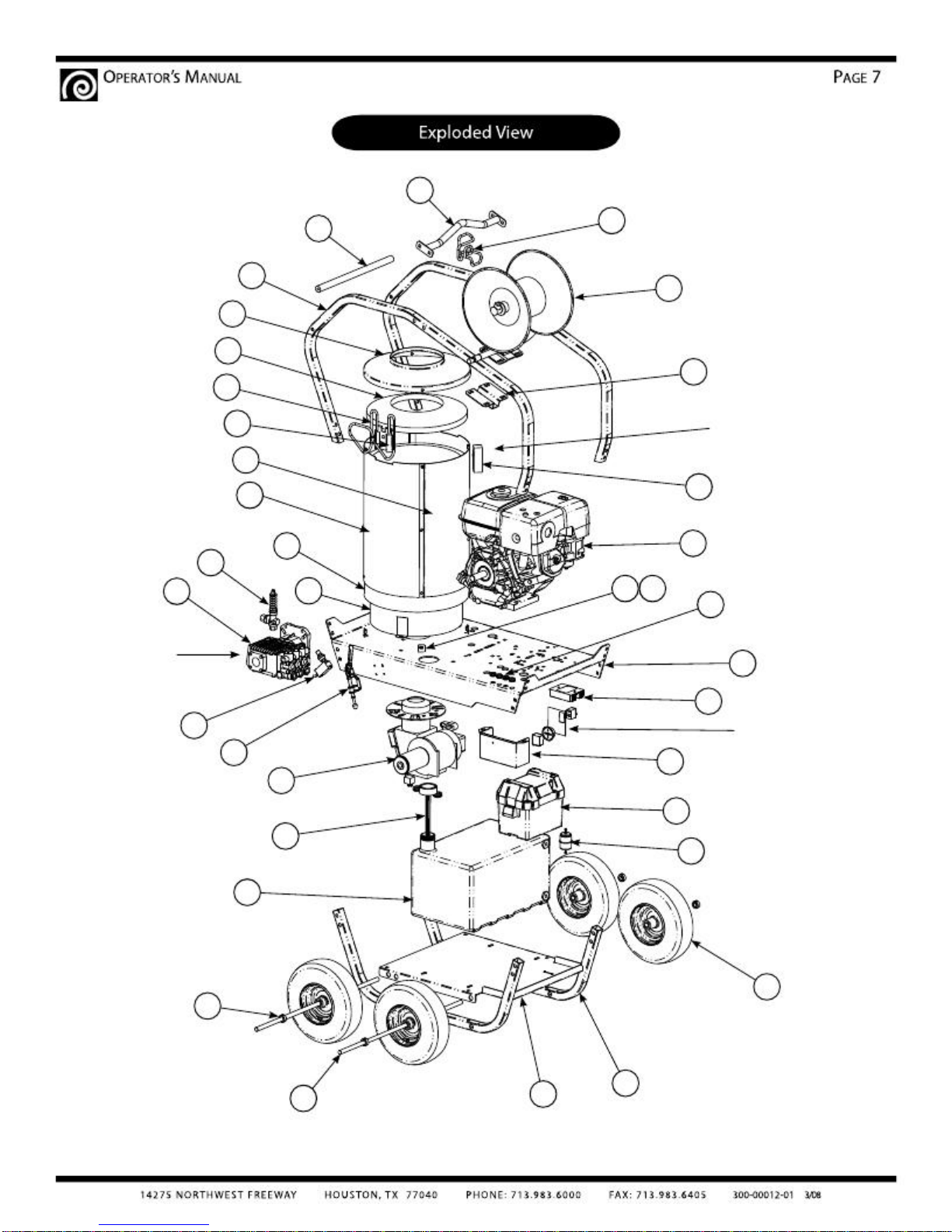

Base

Frame, Lower

Axle, SS,5/8"x 30"

Wheel, pneu,12", tubetype, 1 pc hub, 5/8 brg

Bushing, Wheel Collar, 5/8"

Tank, fuel, 9 gal, black, ID0104H

Filter, fuel, inline

Cap, fuel guage, diesel, black, one way vent

Tray, Battery, vented, black, w/hdwr, 9082-1 1

Power Plate

Engine, Diesel 9.1HP, Kohler KD420

Regulator, for 11/13HP Honda engine

Pump, GP, EZ4030G34

Unloader, Pulsar#3HP, without knob

Pressure switch, GP#YPRESSWITCH

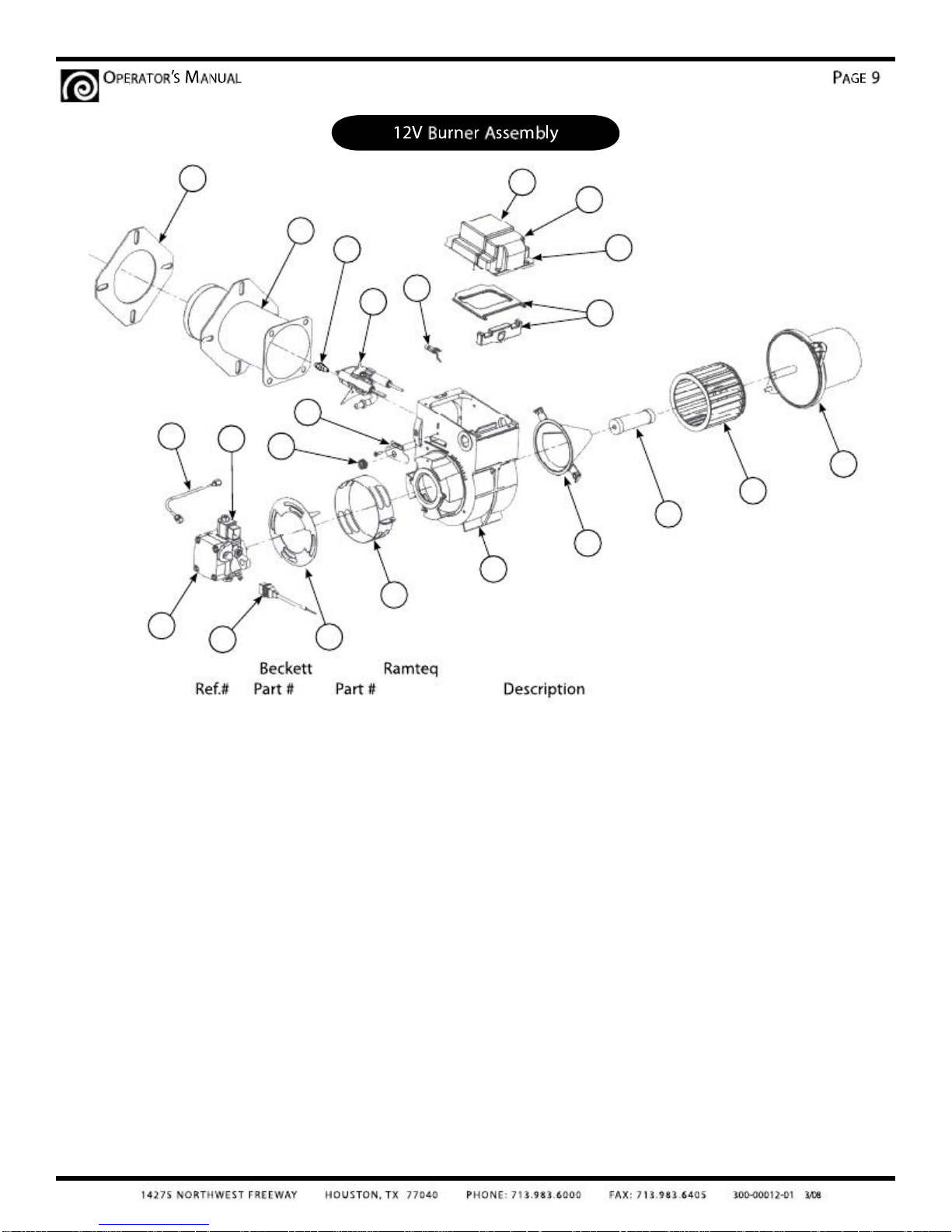

Burner assy, oil, ADC-13.5V, #RTQ202, w/ign

Closeout, Controls

Tab, burner plate

Nut, SP, Cage, 1/4-20, .064-.105

Coil, medium, diesel fired

Insulation, blanket, 1", 24"wide, 4#

Shell, Removable, 16", Round

Shell, Stationary, 16", Round

Bracket,Cord Holder

Cord Holder, Bent wire, chrome plate

Insulation, cap, 16"x8"

Cap, 16", Round Shell

Manifold, outlet

Frame, Upper

Handle, Treaded Rod

Lifting Bar Assy

Wand Holder, wire

Hose Reel

Bracket, Hose Reel Mounting

Brake Assy

Grommet,nozzle holder

Cable, batt,w/terms, black, 25"

Cable, batt, w/terms, red, 42"

Boot, red insulator, B&S 281223

Battery 12v, Group U1,230 Crank Amps

Nozzle, water, #3.5, 0 degr, quickconn

Nozzle, water, #3.5, 15 degr, quickconn

Nozzle, water, #3.5, 25 degr, quickconn

Nozzle, water, #3.5, 40 degr, quickconn

1

2

2

4

4

1

1

1

1

1

1

1

1

1

1

1

4

4

1

49 IN

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1