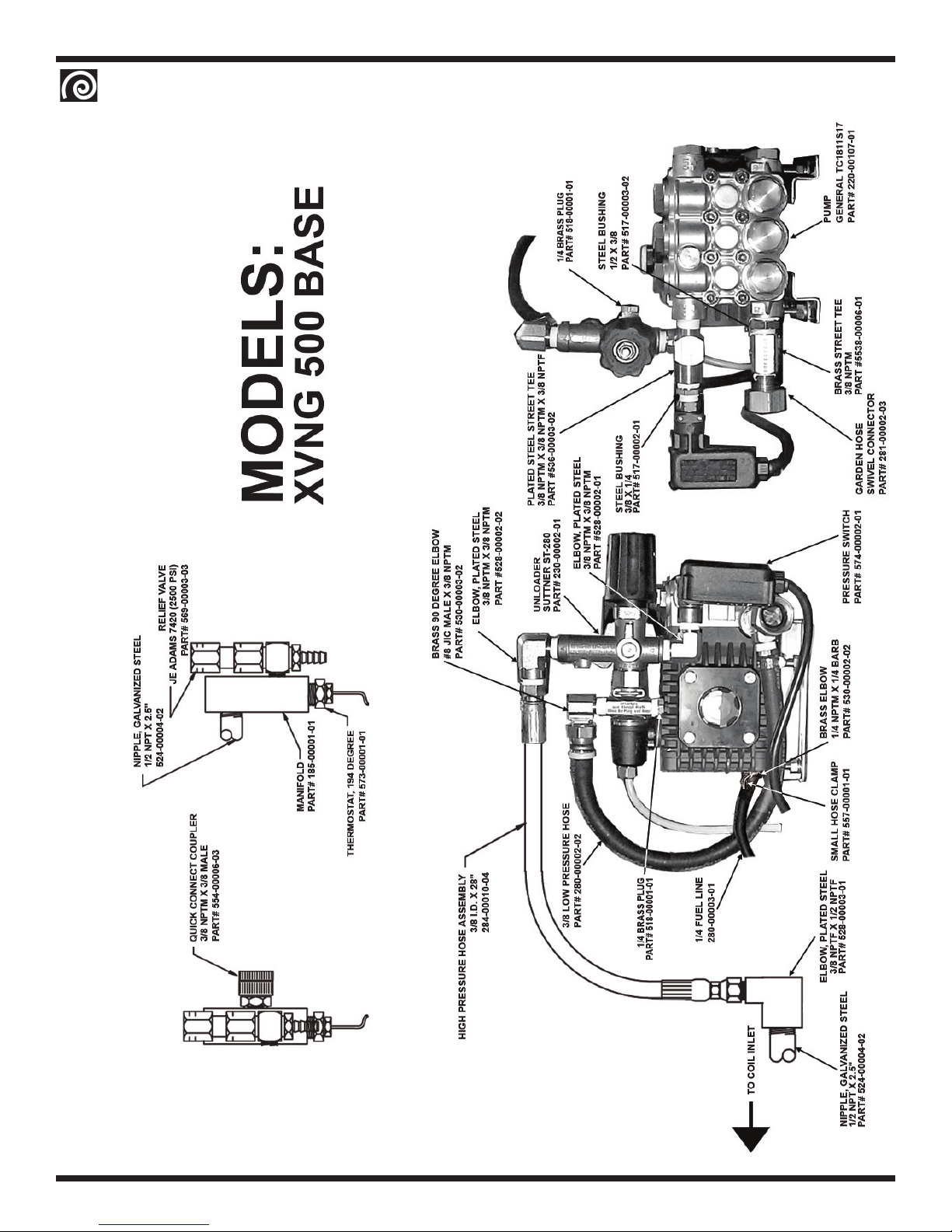

OperatOr’sManual

RAMTEQ®14275 NORTHWEST FREEWAY HOUSTON, TX 77040 PHONE: 713.983.6000 FAX: 713.983.6405 300-00010-03 8/05

page 7

Chassis Components

Part # Description Qty.

180-00300-01 Chassis, XV Series 1

180-00308-01 Handle, XV series (round tubing) 1

180-00030-01 Forklift Tine 4

175-00001-04 (LP version -not shown) Axle, SS, 5/8"x28.5" 2

567-00016-01 (LP version -not shown) Spacer, nylon 4

516-00001-01 (LP version -not shown) Bushing, Wheel Collar 4

170-00007-01 (LP version -not shown) Wheel ,Pneumatic, 12" 4

180-00292-01 Power Plate, XVNG Series 1

180-00298-01 XVNG Belt Guard 1

180-00318-01 XVNG Closeout Panel 1

155-00002-01 XV Coil 1

180-00015-02 XV Coil Shell, Stationary 1

180-00016-02 XV Coil Shell, Removable 1

180-00071-01 XV Coil Cap 1

191-00003-01 XV Coil Cap Insulation 1

180-00382-01 (LP version -not shown) LP Tank Carrier 1

200-00009-01 Motor, 5.0HP, 230/60/1, Baldor L1410T 1

584-00002-40 Pulley, Maska# 2MBL49 1

516-00002-23 Bushing, SP, split taper, Maska# L-1 1/8" 1

220-00093-01 Pump, Comet Model# FW4030S 1

584-00002-43 Pulley, Maska# 2MBL57 1

200-00009-01 Bushing, SP, split taper, Maska# L-1 1/8" 1

XVNG Belt Drive Pumps

General Pump TC1509S17, TC1809S17, TC91811S17 Triplex Pump

Ref.# Part # Description Qty

1a 220-00105-01 TC1509S17 Triplex Plunger Pump Complete (XV150, XV200) 1

1b 220-00106-01 TC1809S17 Triflex Plunger Pump Complete (XV200, XV300) 1

1c 220-00107-01 TC1811S17 Triplex Plunger Pump Complete (XV500) 1

2a 221-0000XX-X Manifold, Brass Head (TC1509S17 & TC1811S17) 1

2b 221-0000XX-X Manifold, Brass Head (TC1809S17) 1

Pump Repair Kits

221-00021-01 Check Valve Assembly Kit #123 (All TC Pumps) 1 kit

221-00003-01 Oil Seal Kit #83 (All TC Pumps) 1 kit

221-0000X-XX Seals, HP, 15mm Kit #196 (TC1509S17 & TC1811S17) 1 kit

221-0000X-XX Seals, HP, 18mm Kit #197 (TC1809S17) 1 kit

221-0000X-XX Rings, 15mm Kit #198 (TC1509S17 & TC1811S17) 1 kit

221-0000X-XX Rings, 18mm Kit #199 (TC1809S17) 1 kit

221-0000X-XX Seals, LP, 15mm Kit #200 (TC1509S17 & TC1811S17) 1 kit

221-0000X-XX Seals, LP, 18mm Kit #225 (TC1809S17) 1 kit

221-0000X-XX Packing, 15mm Kit #226 (TC1509S17 & TC1811S17) 1 kit

221-0000X-XX Packing, 18mm Kit #227 (TC1809S17) 1 kit

1

2