Manual-8

Maintaining Magnetic Faders

ere are no electrical contacts to clean!

e faders in the TTM 56 are designed with materials highly

resistant to corrosion and most chemicals. While the faders will

handle millions of operations, they may become dirty over time.

Bad things may be spilled or sprayed into the faders. In either case,

the faders are not damaged and the sound quality is unaffected.

Cleaning is only required to maintain the feel of the faders.

e faders are self-lubricating and with normal use, should

not require additional lubrication. If you wish, you can use a light

silicone lubricant rated for use with electrical parts. is will help

maintain the feel. We recommend Caig DeoxIT FaderLube

F100

spray lubricant.

Order DeoxIT® F100 from CAIG Laboratories, Inc.

12200 atcher Ct.

Poway, CA 92064

Phone 858-486-8388

Fax 858-486-8398

Web www.caig.com

Never use a heavy lubricant or grease. Doing so will not

damage the faders, but can undo the feel. If grease was used, it may

be removed by following the cleaning instructions. Light lubrica-

tion is possible with the Lexan plate on. A couple of drops or a

short spray are all that is required. Make sure the products you use

are suitable for use with electrical parts that contain plastic.

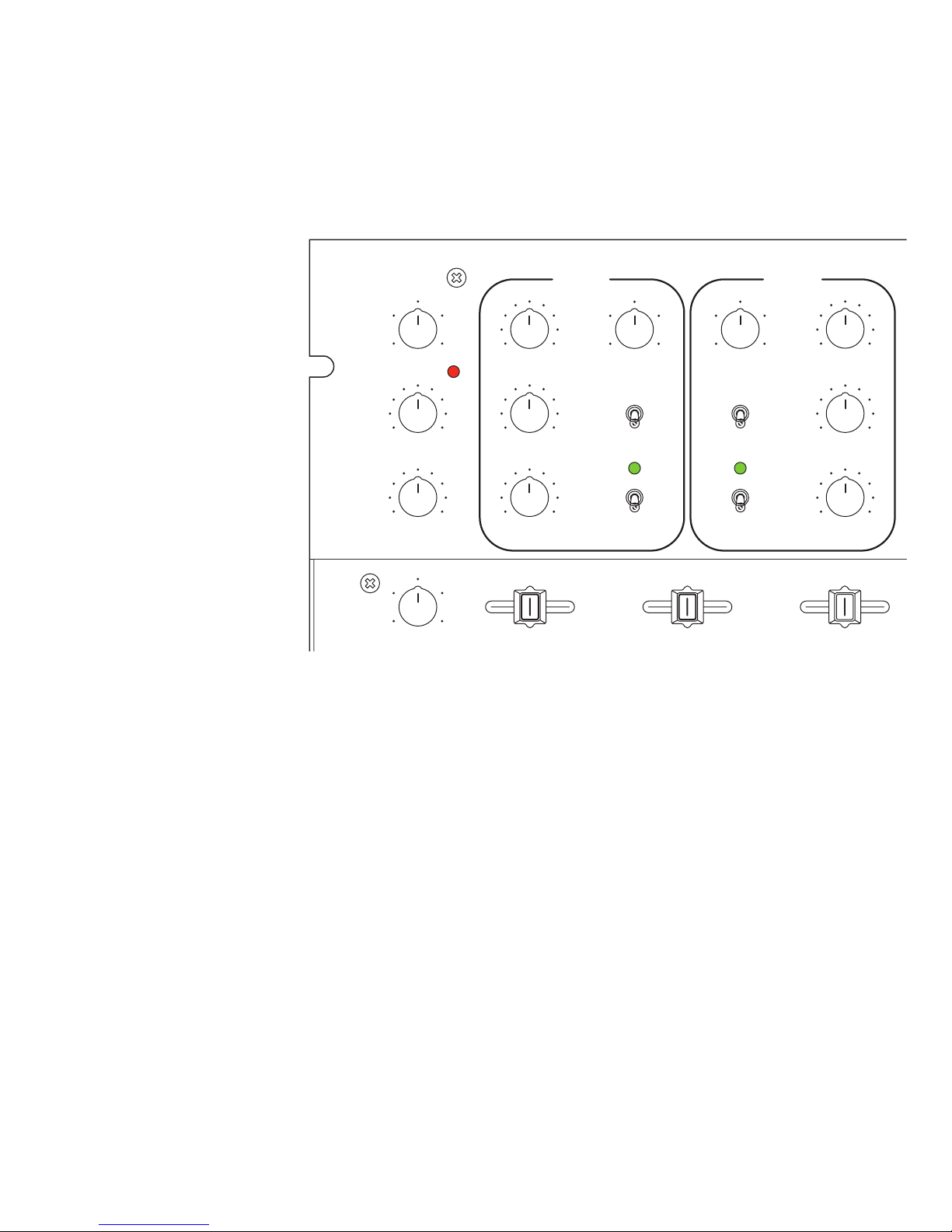

Sensors

Rails

Transform

Switch

Torsion

Spring

Magnetic Slider Rail Cleaning

a. Move the carrier all the way to one side.

b. Use a soft lint-free cloth to wipe off rails.

c. Add a drop of silicone lubricant (or quick spray from aerosol) to the center of each rail.

d. Move the carrier back and forth to distribute lubricant.

e. Do not bend torsion spring or touch sensors.

Magnetic Fader Q and A

Q: Will I damage the faders if I spray them with bad stuff or spill

bad things in them?

A: No. e faders in the TTM 56 are designed with materials high-

ly resistant to corrosion and most chemicals. ere are no electri-

cal contacts to clean or damage. While bad things may change the

feel of the faders, bad things will not affect the sound. To clean

faders that have had a bad thing put in them, follow the simple

instructions on page Manual-8.

Q: Can I install magnetic faders in any other mixer?

A: Sorry. e connectors may be similar, but the circuits are very

different. Connecting the faders to anything other than the in-

tended cable in the TTM 56 could permanently damage them.

Q: Can I install other faders in my TTM 56?

A: No. e cable connections are specially designed for Rane mag-

netic faders.

Q: Can I install a different magnetic fader in my mixer or swap

the position of my faders?

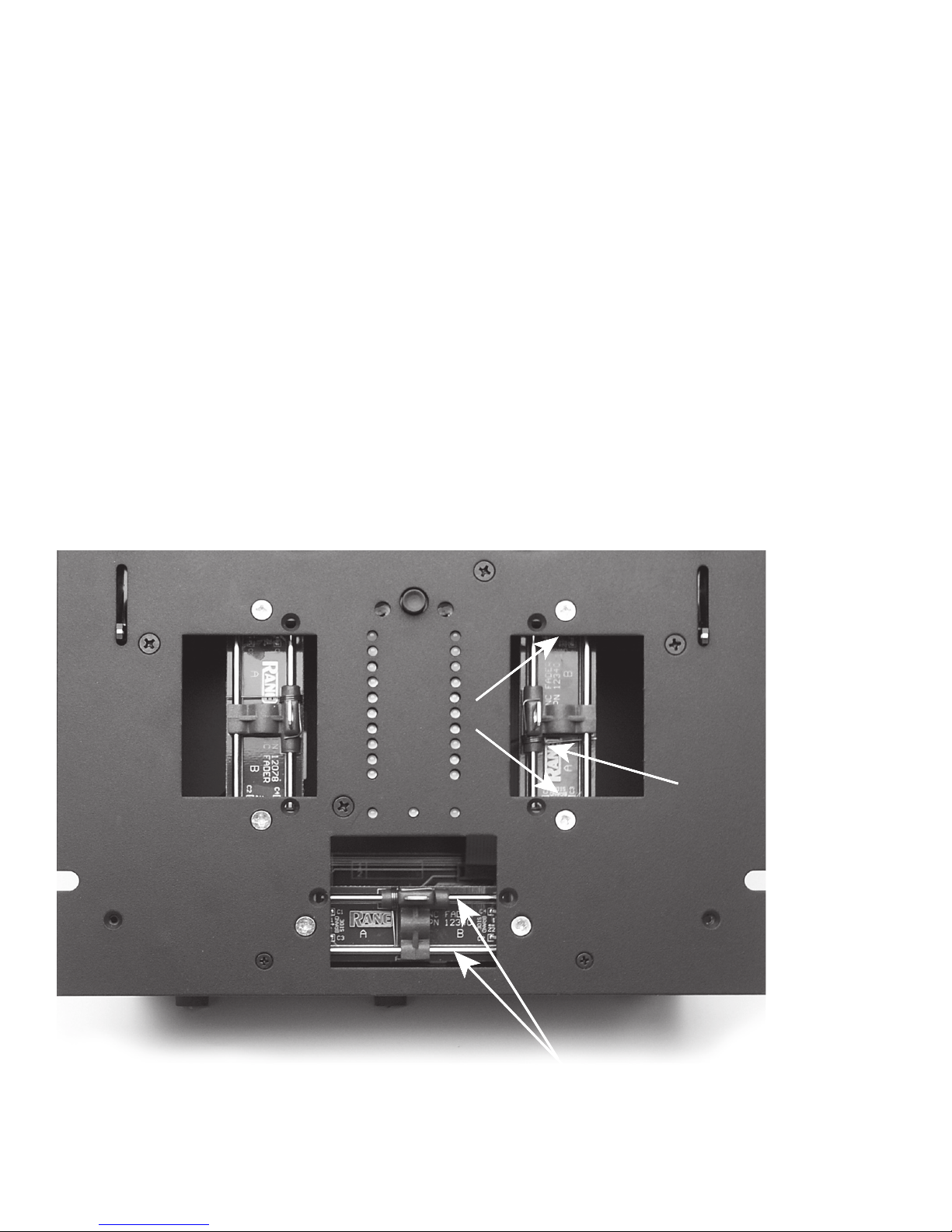

A: No. In order to achieve the highest possible accuracy, each

magnetic fader is factory calibrated for the location in which it

was shipped. For information about replacement or calibration,

contact Rane Customer Service. If you remove the faders for

cleaning, make sure you mark them. is helps you to put them

back in the same location.