3

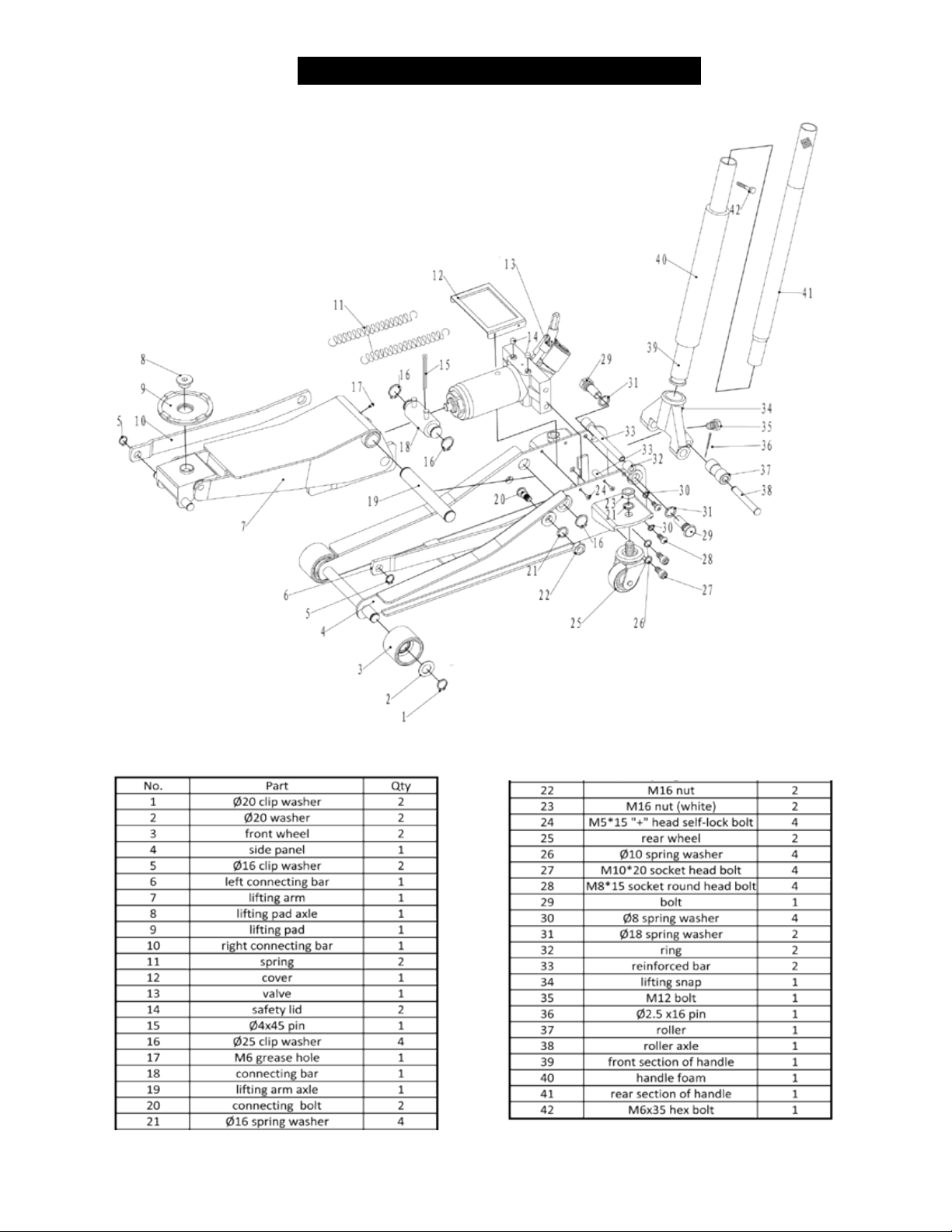

ASSEMBLY INSTRUCTIONS

1. Remove 2-piece handle from box. Insert narrow portion

of top section (41) into bottom section (39) and secure

with bolt (42) provided.

2. Then, slightly press down on the handle yoke

assembly to release pressure on the handle yoke

assembly retainer and remove retainer. This will allow

handle yoke to be raised to operating position.

3. Grease handle receptacle and insert slotted end

of handle into place. Tighten set screw (35) to secure

handle.

OPERATING INSTRUCTIONS

BEFORE USE:

Air may become trapped in the hydraulic system during

transit. To purge air:

1. Open release valve by turning handle counterclock-

wise.

2. Pump handle rapidly 4 full strokes. This will expel air

that may have entered oil passages during transit.

3. Close release valve by rotating handle clockwise and

pump handle.

4. If lift arm is raised, jack is ready for use. If not, repeat

this procedure.

IMPORTANT:

Before attempting to raise any vehicle, check

vehicle service manual for recommended lifting surfaces.

OPERATION:

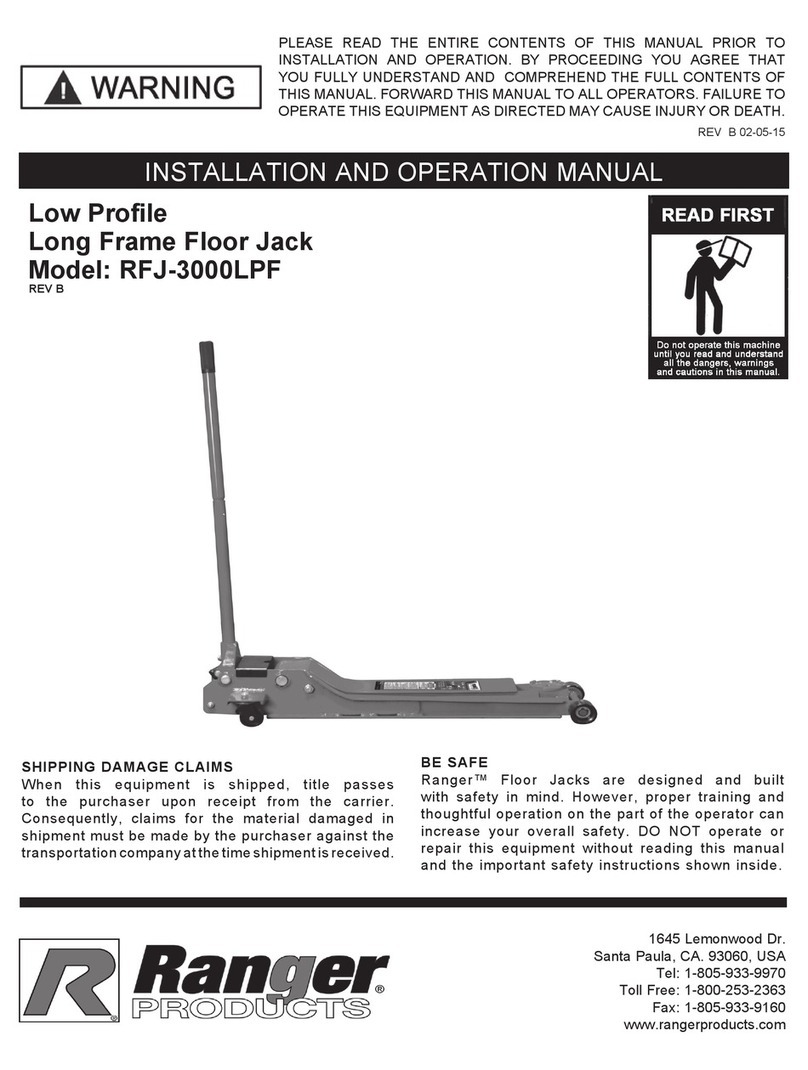

1. To Raise Load: Close release valve tightly (by turning

handle clockwise). DO NOT OVERTIGHTEN. Position

jack under load so that saddle will contact load rmly and

load is centered so it cannot slip. Operate jack handle un-

til saddle approaches the load. Once again, check to see

that saddle is correctly positioned. Raise load to desired

height. Place jack stands of appropriate capacity under

the vehicle. DO NOT CRAWL UNDER VEHICLE WHILE

LIFTING VEHICLE OR PLACING OR REMOVING JACK

STANDS!

Place jack stands at vehicle manufacturer’s recommend-

ed lift areas that provide stable support for the raised

Vehicle. Once jack stands are positioned, open the

release valve VERY SLOWLY (by turning the handle

counterclockwise).

Lower the load to rest on the jack stands. Then, make

sure that the release valve on the jack is closed tightly

(by turning the handle clockwise).

2. To lower load:

Re-check to make sure release valve is tightly closed.

Then, operate the jack handle until the load is raised

enough to remove the jack stands.

DO NOT CRAWL UNDER VEHICLE WHILE LIFTING

VEHICLE OR REMOVING THE JACK STANDS!

Once jack stands are removed, open release valve very

slowly to lower the vehicle. Lower jack completely so that

the vehicle is securely resting on the ground and that jack

no longer makes contact with vehicle.

Keep hands or feet away from the

hinge mechanism of the jack.

MAINTENANCE

When adding or replacing hydraulic uid, always use a

quality hydraulic uid. DO NOT use brake uid, alcohol,

detergent motor oil, dirty oil or any uid other than quality

hydraulic uid. Improper uids can cause internal dam-

age to the jack and improper or unsafe operation.

Adding Hydraulic Fluid

With the saddle fully lowered and the jack on level

ground, remove the ller screw. Hydraulic uid should

be lled to the level of the ller screw hole. If the level is

below this hole, add hydraulic uid as needed.

LUBRICATION

All moving joints require lubrication often. Lightly grease

saddle post and saddle bottom. Remove handle and

grease the lower end of handle where it rotates in the

handle socket. Using a grease gun, grease the lift arm

pivot shaft grease tting until grease appears at the end

of the shaft. Oil all lift arm linkages, front wheels and rear

casters.

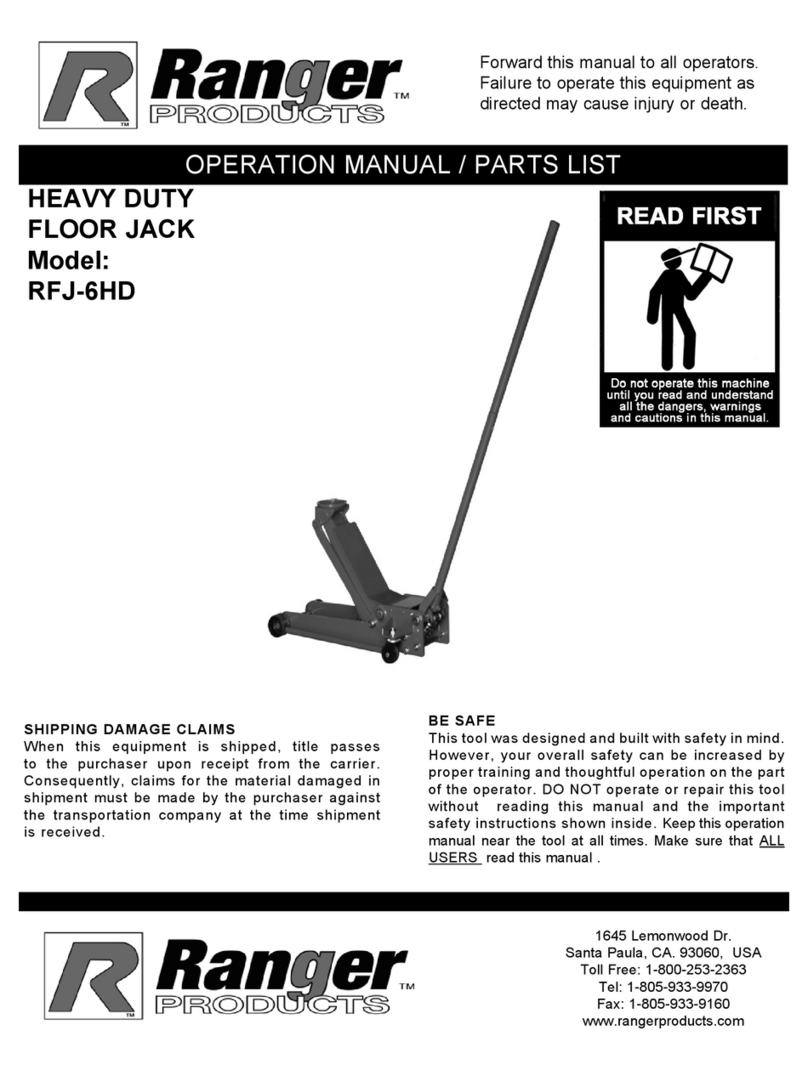

SPECIFICATIONS

Rated Load Capacity: 5000 lbs. (2268 kg.)

Minimum Height: 3” (76mm)

High height 20” (508mm)

Front Overall Width 10-1/2” (267mm)

Rear OVerall Width 14” (356mm)

Shipping Weight 74lbs. (34 kg.)