Ratek controllers use a custom program securely contained as firmware in a

single microprocessor.

User interface is via front panel mounted key switches and LED display.

Program settings are maintained by a non-volatile RAM. System

performance is monitored by a “watch dog” that resets the system if power is

interrupted.

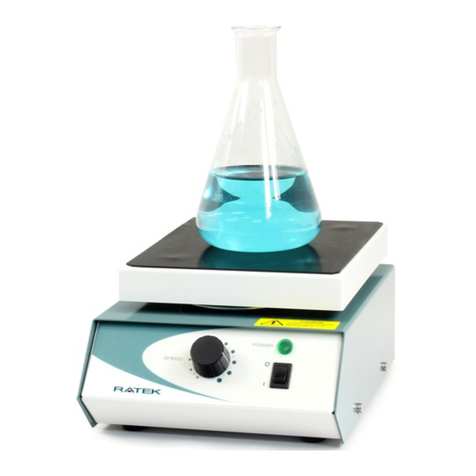

Separate function switches are provided for independent operation of the

mixing and heating, These switches are located under their respective

control sections on the front panel.

Ensure that the load is properly secured before starting the mixer.

Do not run heavy loads at high speed.

The motor control circuit has a built in safety feature which is designed to

protect the drive against abnormal conditions.

If the platform becomes jammed, or an excessive load is detected, drive to

the motor will be cut.

To restore normal operation, remove the obstruction or excessive load, turn

the power switch off, then on again.

The clear acrylic cabinet can be easily removed in one piece to allow full

access for cleaning. When refitting ensure the cabinet is located securely in

the locating strips.

Power requirements: 240 VAC/ 540 Watts

Control type: Custom digital microprocessor

Temperature control Range: Ambient + 6°to 75°C

Control stability: ±0.2

Display resolution: 1°C

Heater type: Fan assisted spiral wound element.

Mixer control range: 40-400 rpm with Tachometer.

Timer: 0-99 hours/minutes with 3 adjustable

presets.

Mixer platform: 400 X 400mm Max weight 8 kg’s

Safety features: Adjustable over temperature alarm.

Independent mechanical cut out

Motion interrupt drive cut off

SERVICE

Should the unit fail to operate correctly, any service work should be

carried out by a qualified technician.

Unauthorised tampering will invalidate the manufacturer’s

guarantee.