3

1. SAFETY INSTRUCTIONS

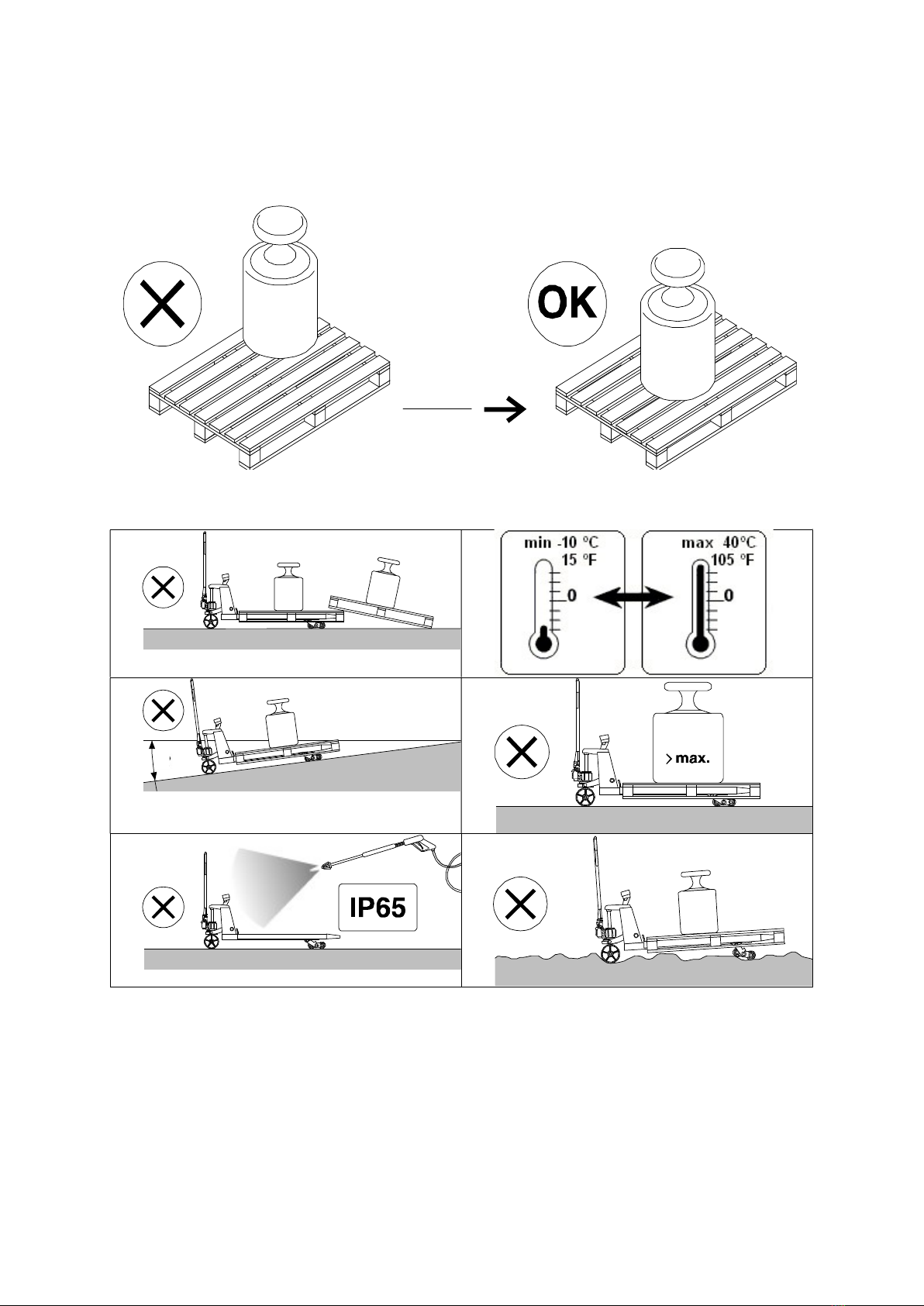

1. NEVER lift a heavy load with just the tip of the forks. This could damage the electronic

weighing elements permanently.

2. NEVER weigh without a pallet. This could affect the accuracy of the weighing result.

3. The unit may be loaded with weights up to 5000 lb. However we advise you not to move any

weights above 1650 lb. (750 kg) with the unit. RAVAS is not responsible for injury that may

result when moving heavy loads.

4. Use caution in the vicinity of moving parts - these parts can cut and/or crush hands, arms, feet

and legs.

5. Always center the load you are lifting on both the forks.

6. Do not operate the weighing system on ramps, inclines or declines, without the addition of our

optional parking brake.

7. Do not operate the weighing system while others are on or near the unit. No riding!

8. All modifications must be approved in writing from the supplier, prior to any work being

completed.

9. It is the sole responsibility of the purchaser to train their own employees in the proper use and

maintenance of this equipment.

10. Do not operate this unit unless you have been fully trained of its capabilities.

11. Do not use the weighing system in potentially explosive areas.

12. Do not carry passengers with the truck.

13. Do not weld or make changes to the weighing system without consulting the supplier.

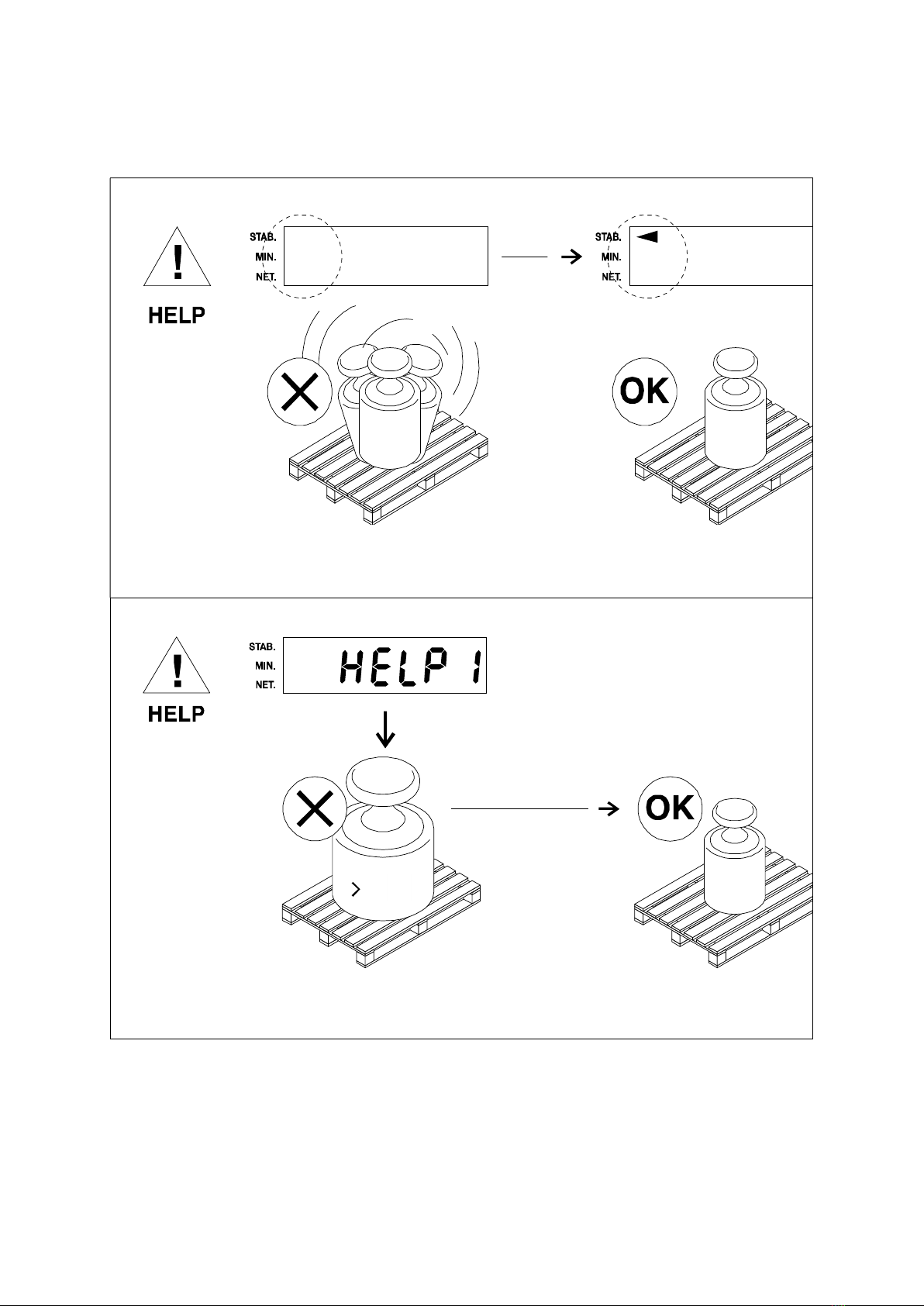

14. Do not lift unstable loads.

15. Check the accuracy of the scale on a regular basis to prevent faulty readings.

16. Only trained and authorized personnel are allowed to operate the truck.

17. Always follow the operating, maintenance and repair instructions of this truck and ask the

supplier when in doubt.

18. Never lower loads if you are unsure you can place the goods on a stable surface. Personal

injury may result from placement on an unstable environment.

19. Always remain with the scale during dosing applications. Incorrect lifting of the pallet can

cause overflowing.

20. RAVAS USA is not responsible for errors that occur due to incorrect weighings or inaccurate

scales.