INSTALLATION INSTRUCTION & OPERATION MANUAL PowerPlus System 100-3-1U

www.raycap.com

© Raycap | All rights reserved. •(320-1398) QRC | Rev.B

Page 1 of 30

Table of Contents

1. Copyright............................................................................................................................................................ Page 2

1.1 Disclaimer .........................................................................................................................................2

1.2 Warnings ...........................................................................................................................................2

2. Introduction................................................................................................................................................................... 3

3. Package Contents......................................................................................................................................................... 3

3.1 Prerequisites .....................................................................................................................................3

3.2 Tools..................................................................................................................................................3

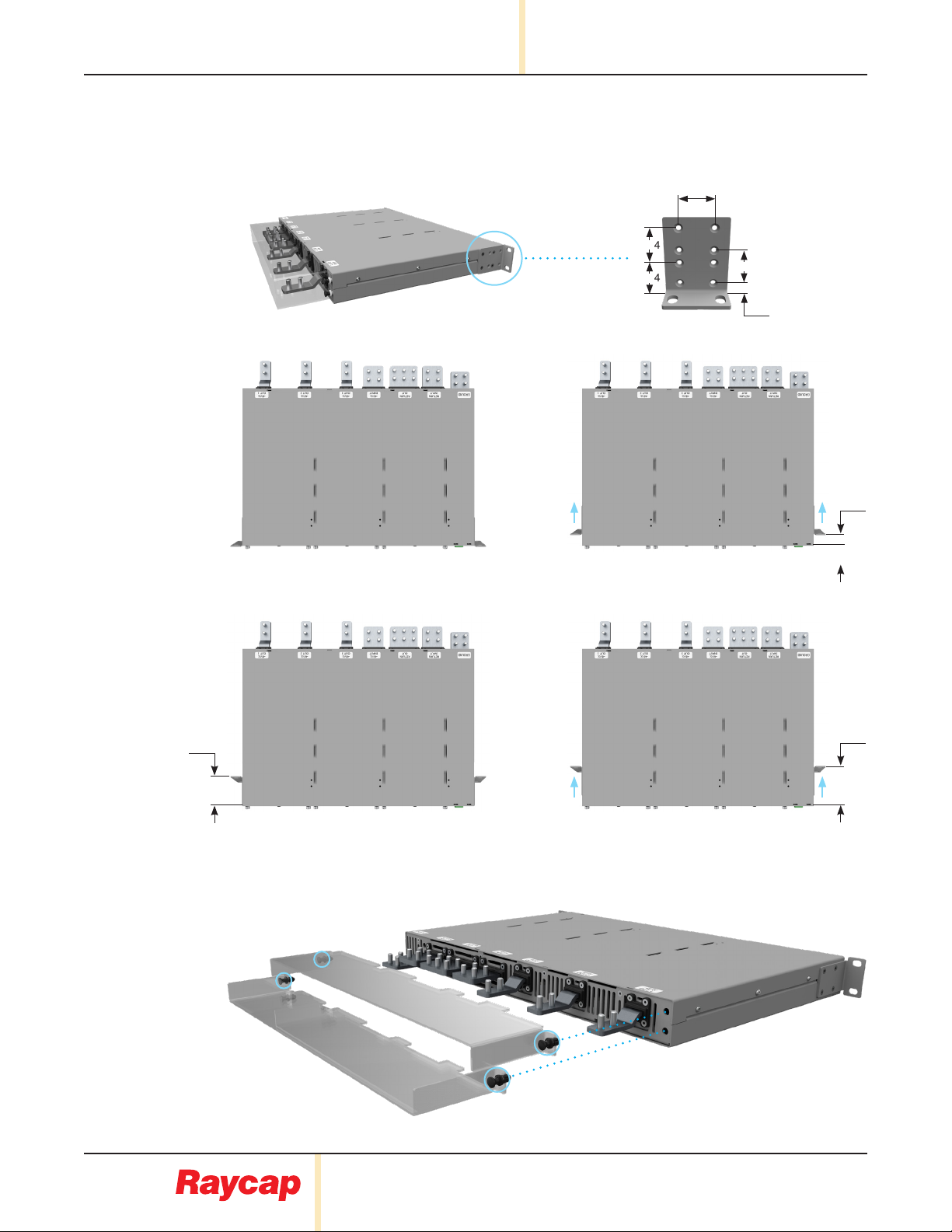

4. Mounting .......................................................................................................................................................................4

5. General Description ...................................................................................................................................6

5.1 Functionality ......................................................................................................................................6

5.2 Modes of Operation...........................................................................................................................6

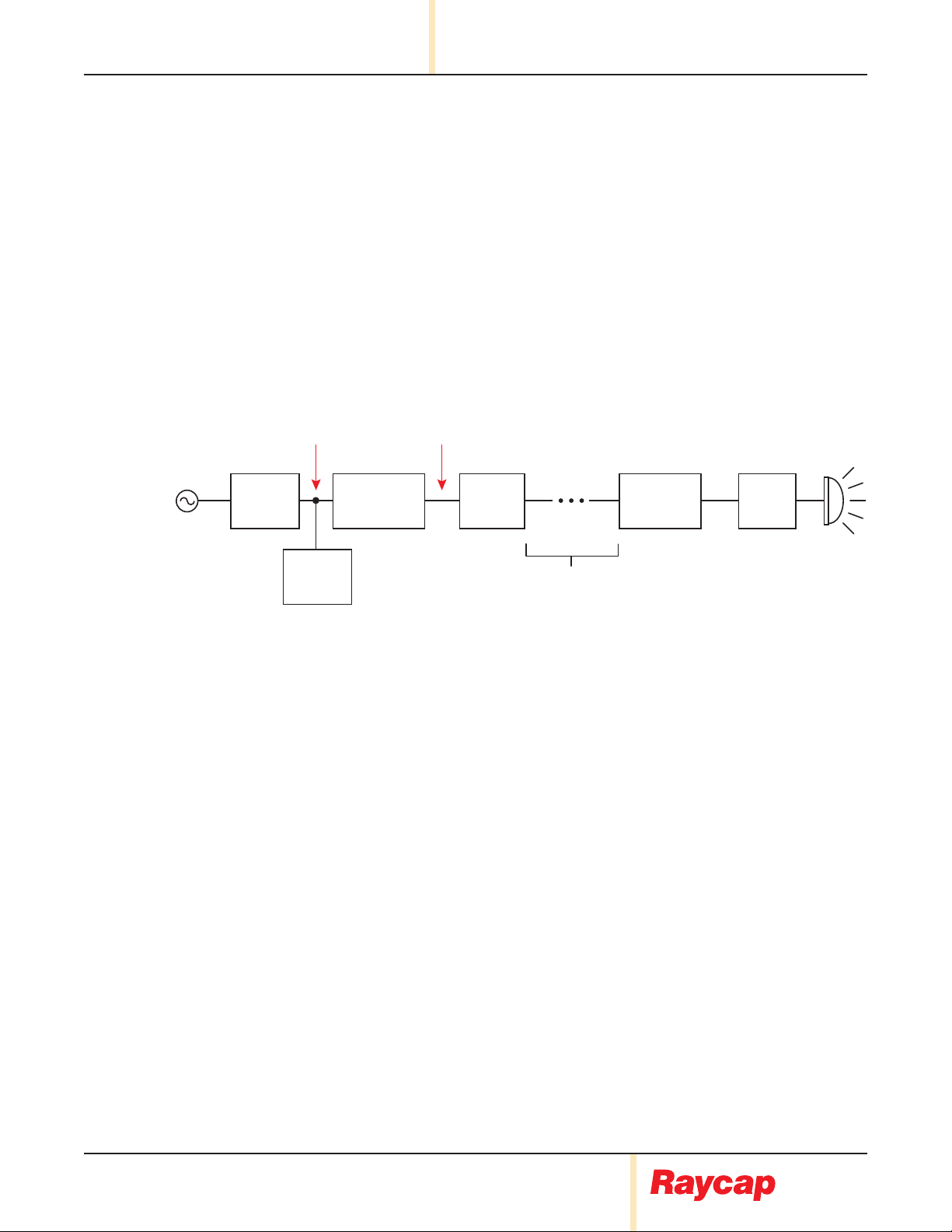

5.3 System Topology ...............................................................................................................................7

5.4 InstallationCongurations.................................................................................................................8

5.5 ModuleCongurations .................................................................................................................9-13

6. System Management................................................................................................................................14

6.1 Modules...........................................................................................................................................14

6.2 Module Failure.................................................................................................................................15

6.3 Primary Failure................................................................................................................................15

7. Modules.....................................................................................................................................................16

7.1 Module Replacement ......................................................................................................................16

7.2 Cold Module Replacement..............................................................................................................17

7.3 Hot Module Replacement................................................................................................................17

7.4 Hot Module Replacement: Invalid Module Installation.....................................................................17

8. Module Settings........................................................................................................................................18

8.1 Settings Menus ...............................................................................................................................18

8.2 Initial Settings Menu........................................................................................................................18

8.3 Initial Settings Menu: Mode Selection .............................................................................................19

9. Parallel Mode Settings .............................................................................................................................20

10. Single Mode Settings...............................................................................................................................21

11. Live Settings Menu...................................................................................................................................22

12. Bus Bar......................................................................................................................................................24

13. Alarms .......................................................................................................................................................25