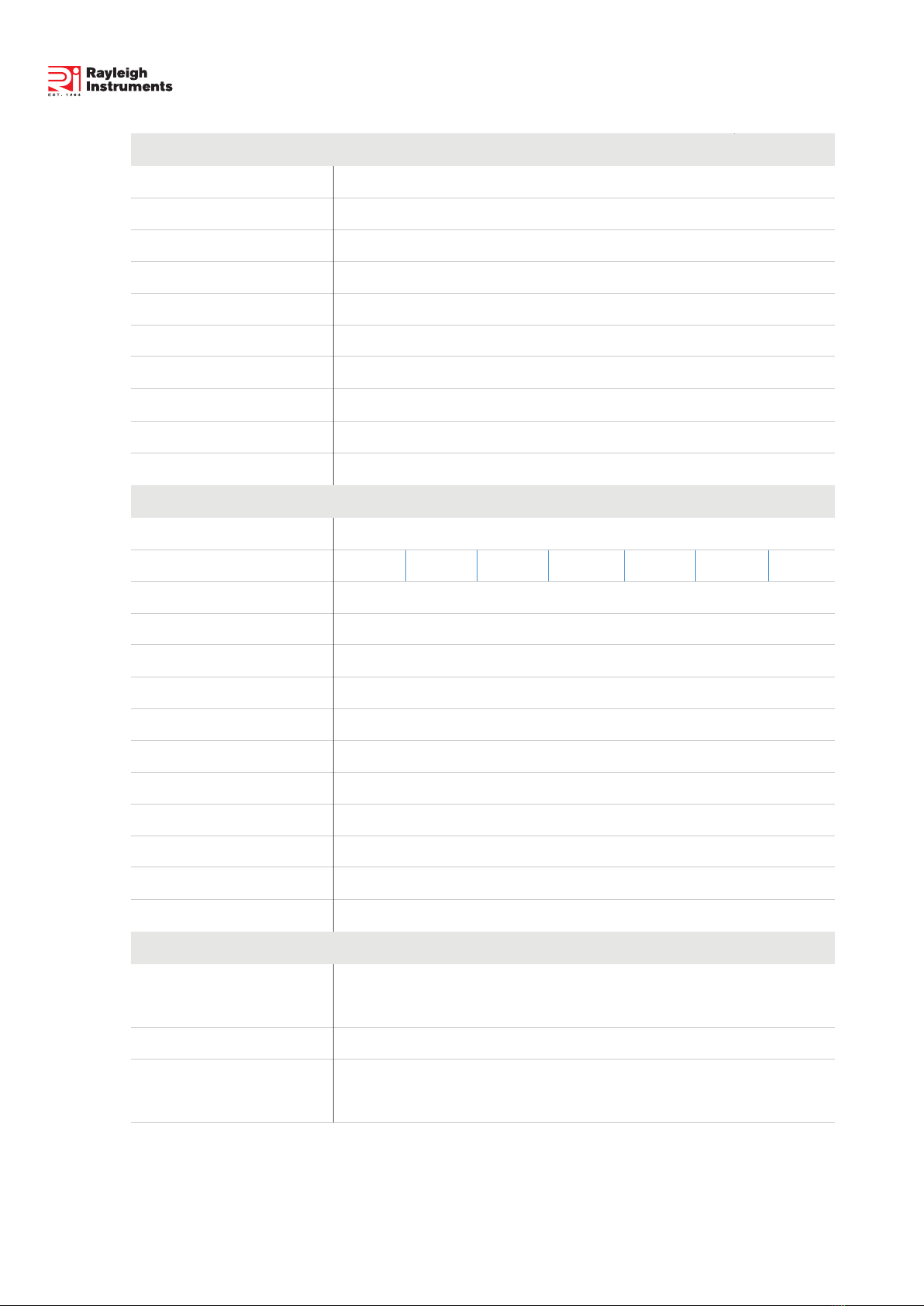

2.4 Grid codes

16.3KG 16.3KG 16.3KG 18.3KG 18.3KG 18.3KG 21.6KG

98.1%

97.5%

99.9%

97.8%

97.2%

99.9%

Integrated

Integrated

Integrated

Integrated

Integrated

Integrated

Integrated

Integrated

Integrated (Type III)

Integrated (Type III)

395 x 330 x 185mm 455x390x160mm 455x390x190mm

LCD

RS485 (Standard), Wifi or GPRS

-25 ℃~ 60 ℃

0-100%

≤ 4000m

< 0.2W

Transformerless

Natural Convection

IP65

< 30dB

5 / 7 / 10 years

C10/11, PEA, MEA, G98, G99, EN50549,CEI 0-21, CEI 0-16, IEC61727, IEC62116,

IEC60068, IEC61683

IEC 62109-1, IEC 62109-2

EN 61000-3-2, EN 61000-3-3, EN 61000-3-11, EN 61000-3-12, EN 61000-6-2,

EN 61000-6-3, IEC 61000-4-16, IEC 61000-4-18, 4-29

Protection

DC Insulation Monitoring

Input Reverse Polarity Protection

Anti-island Protection

Residual Current Monitoring

Over-heat Protection

AC Overcurrent Protection

AC Short-circuit Protection

AC Overvoltage Protection

DC Surge Protection

AC Surge Protection

General Data

Size(Width*Height*Depth)

Weight

User Interface

Communication

Ambient Temperature Range

Relative Humidity

Operating Altitude

Standby Self Consumption

Topology

Cooling

Protection Grades

Noise

Warranty

Certifications & Standards

Grid Regulation

Safety Regulation

EMC

Belgium power Grid.

UK power Grid.

China power Grid, meet Grid standards “CN-NBT”.

France power Grid, meet Grid standards “VDE 0126”.

Poland power Grid.

Germany power Grid, meet Grid standards “BDEW-MV”.

Germany power Grid, meet Grid standards “VDE 0126”.

Italy power Grid, meet Grid standards “CEI 0-16”.

UK power Grid.

Greece Island power Grid.

Czech Republic power Grid, meet Grid standards “EN50438Y2007-CZ”.

India power Grid.

Korea power Grid.

Sweden power Grid.

China power Grid, Grid voltage range:160-290V

Grid frequency range:47-53HZ.

China power Grid, meet standards“CQC ”.

India power Grid, meet Grid standards “IEC61727”.

Brazil power Grid , meet Grid standards “NBT 16150”.

Sri Lanka power Grid, meet Grid standards “IEC61727”.

Mexico power Grid, meet Grid standards “IEC61727 60HZ”.

New Zealand power Grid, meet Grid standards “NZ4777”.

Philippines power Grid, meet Grid standards “IEC61727 60HZ spec”.

Sri Lanka power Grid, Grid voltage range:160-290V, Grid frequency range:47-53HZ.

Thailand power Grid.

Thailand power Grid, Grid voltage range:160-290V, Grid frequency range:47-53HZ.

Vietnam power Grid.

Vietnam power Grid, Grid voltage range:160-290V, Grid frequency range:47-53HZ.

Thailand power Grid.

Thailand power Grid, Grid voltage range:160-290V, Grid frequency range:47-53HZ.

Tunisia power Grid.

Tunisia power Grid, Grid voltage range:160-290V, Grid frequency range:47-53HZ.

C10/11

G59

China

VDE0126-FR

EN50549-PL

BDEW-DE

VDE0126-DE

CEI0-16

G83

Greece Island

EN50549-CZ

IEC61727

Korea

EN50549-SW

China-W

China-H

IEC61727-IN

Brazil

IEC61727-SL

Mexico

NZ4777

Philippines

IEC61727-SL-W

PEA

PEA-W

IEC61627-VN

IEC61627-VN-W

MEA

MEA-W

Tunisia

Tunisia-W

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

DescriptionNational/Regional Grid Code

No.

Telephone : +44 (0) 1245 428500

Email : sales@rayleigh.com

7