Contents

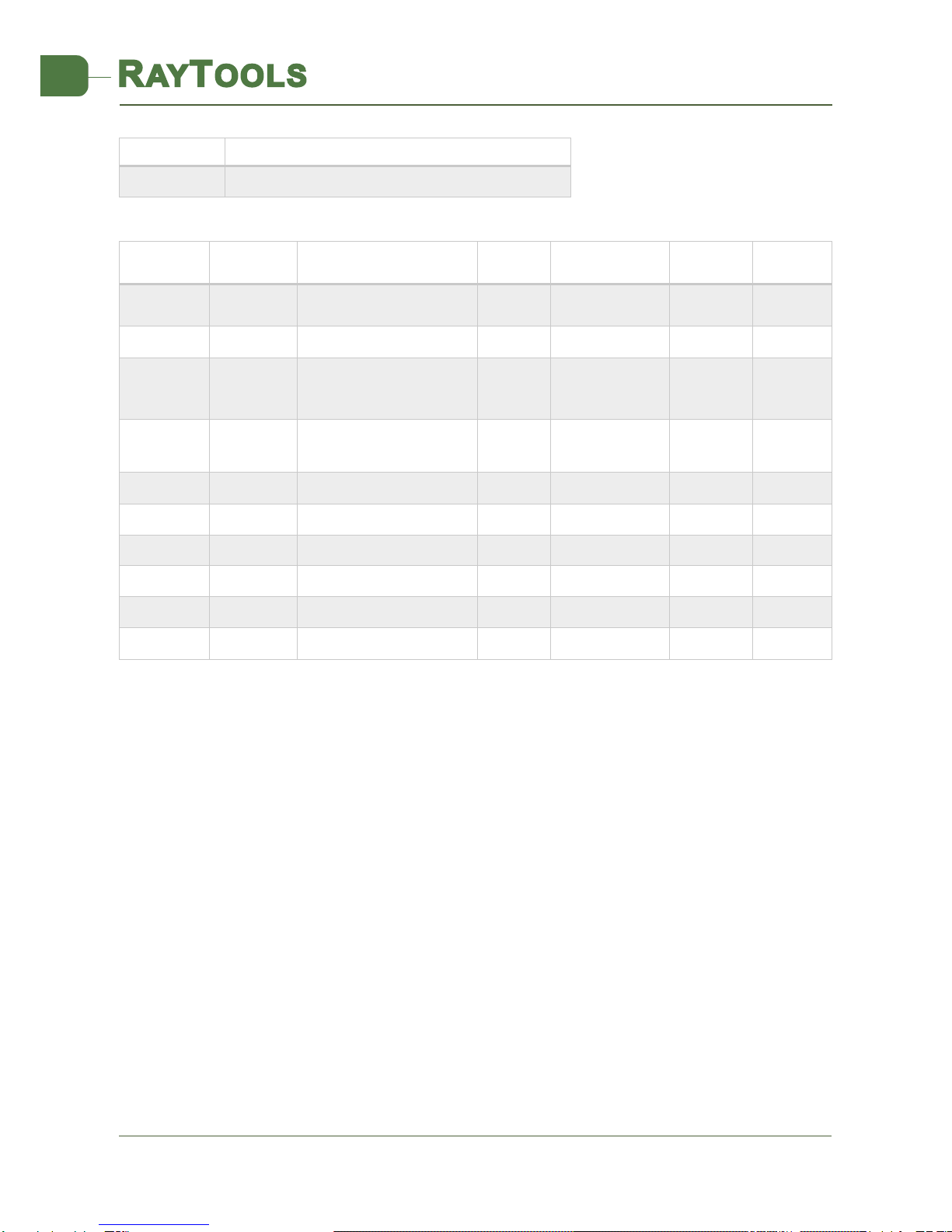

1 Summary.......................................................................................................................................... 4

1.1 Product Advantages ..............................................................................................................4

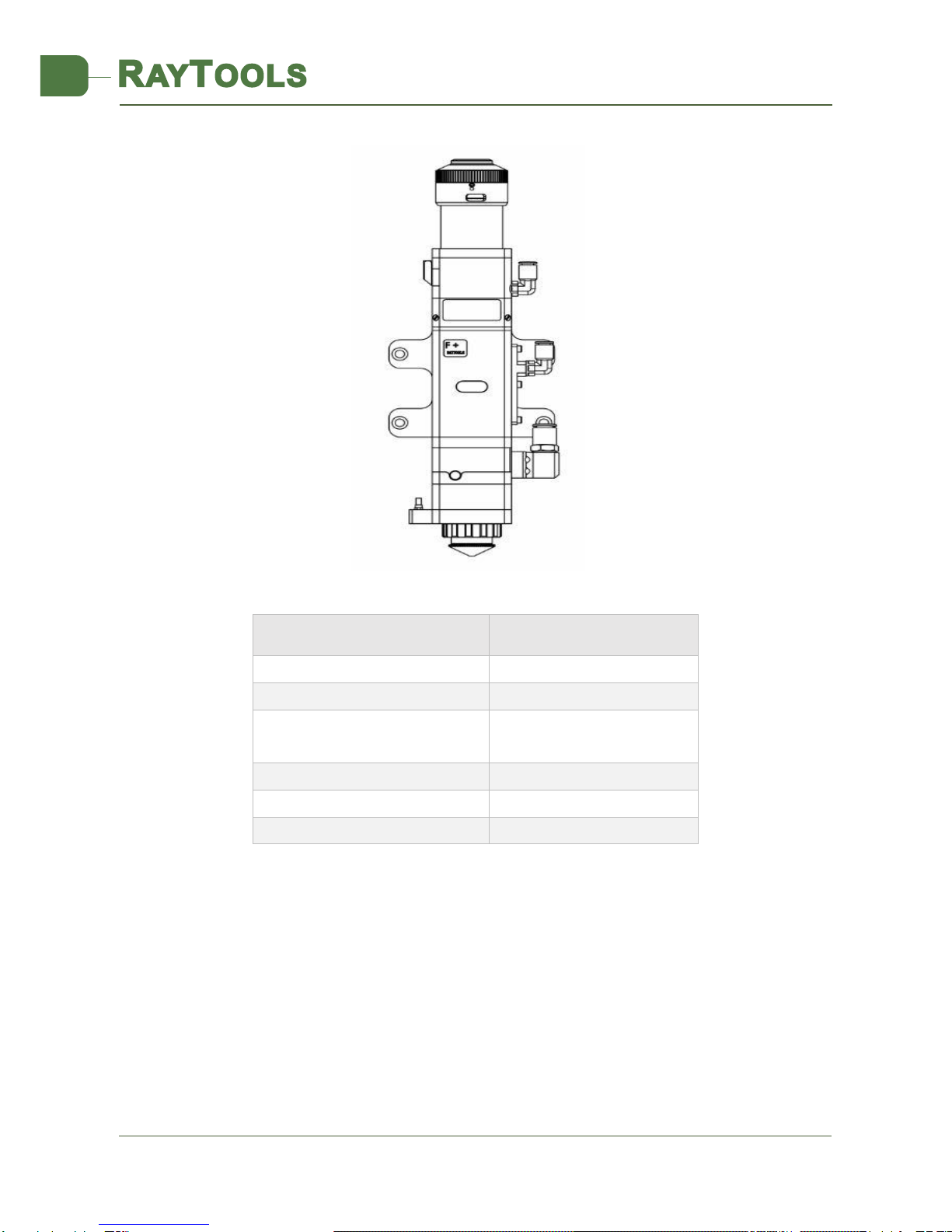

1.2 Structure & Function ............................................................................................................5

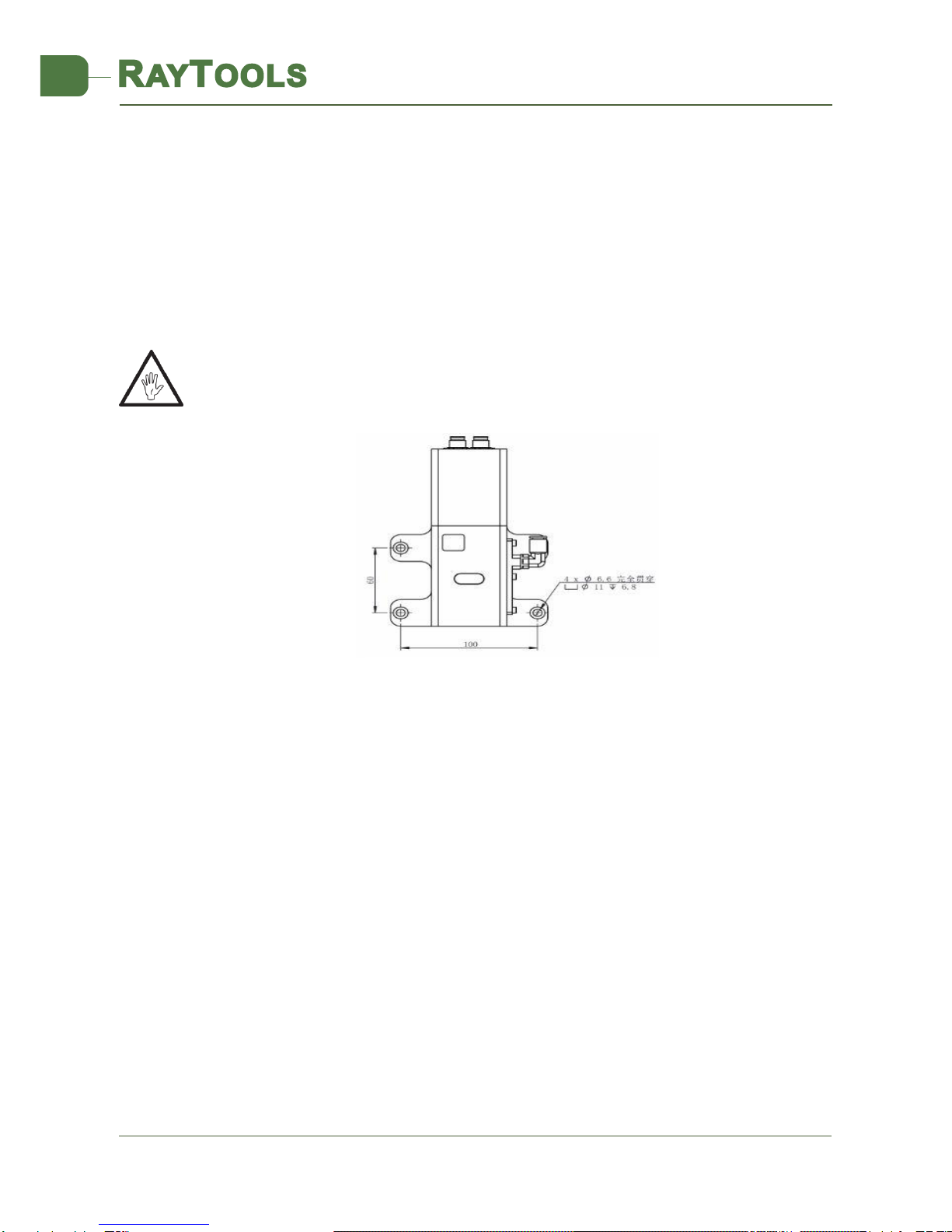

2 Machinery Installation ..................................................................................................................... 6

2.1 Hole Site installation .............................................................................................................6

2.2 Connection of Water Pipe and Gas Pipe...............................................................................6

2.2.1 Water-cooled Interface .................................................................................................6

2.2.2 Assist Gas Interface....................................................................................................7

2.3 Connection of Cutting Head Cable........................................................................................8

2.3.1 Connection of Cutting Head and Cable.........................................................................8

2.3.2 Connection Cable and Driver Connection..................................................................9

2.4 Fiber Input Interface .............................................................................................................9

2.5 Fiber Insertion and Interface Direction Adjustment.............................................................9

3 System Installation Commissioning ............................................................................................... 11

3.1 Non-bus Position Loop-BC ..................................................................................................11

3.1.1 Distribution .................................................................................................................11

3.1.2 Software Settings ........................................................................................................12

3.1.3 Interface Operation.....................................................................................................12

4 Beam Adjustments and Focusing...................................................................................................14

4.1 Beam Adjustments (QBH Interface)....................................................................................14

4.2 The Focus Position Adjustment ..........................................................................................15

5 Maintenance .....................................................................................................................................16

5.1 Cleaning Lens ......................................................................................................................16

5.2 Removal and Installation of Lenses ....................................................................................17

5.2.1 Removal and Installation of Protective Lenses ...........................................................17

5.2.2 Removal and Installation of Collimating Protective Glasses....................................17

5.2.3 Removal and Installation of Collimating Lenses .........................................................18

5.3 Replace Nozzle Connector ..................................................................................................21