6

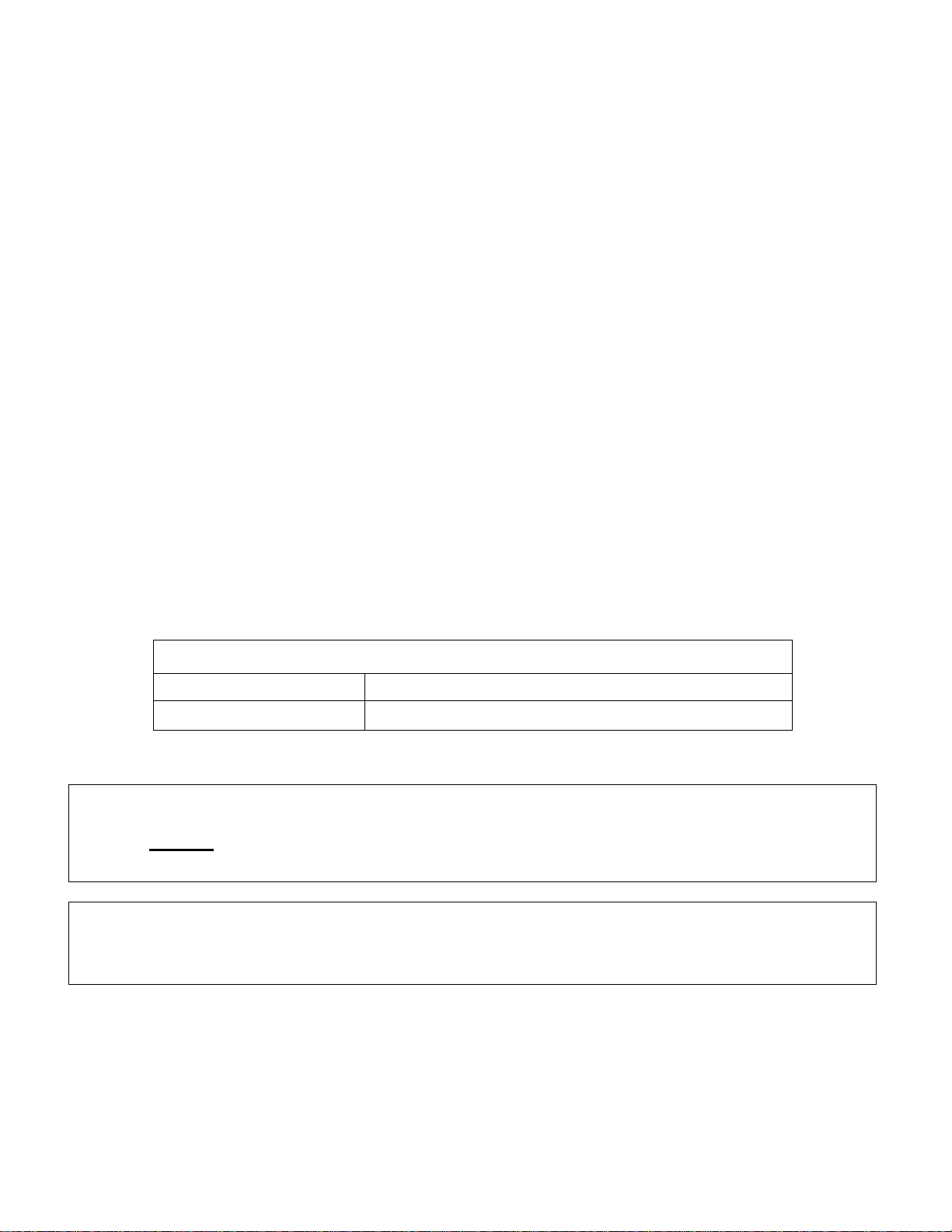

Rear Wheel Installation with Standard Axle Bolt – SP Model

Tools needed: ¾” socket wrench, ¾” wrench

1. Remove wheels from shipping carton.

2. Remove axle bolts and nuts from carton divider.

3. Remove hubcap from one wheel by twisting hubcap counter clockwise.

4. Insert axle bolt through the wheel hub.

5. Place axle-wheel assembly into axle receiver on plate.

6. Thread nut onto axle bolt and tighten until wheel assembly is secure.

Do not over-tighten as wheel must spin freely.

7. Replace hubcap by turning it counter clockwise with wheel stationary.

8. Repeat steps 3 to 8 for other wheel.

Rear Wheel Installation with Optional Quick-Release Axle – SP Model

Tools needed: ¾” wrench, 7/16” wrench

1. Remove wheels from shipping carton.

2. Remove quick release axles from carton divider.

3. Remove hubcap from one wheel by twisting hubcap counter clockwise.

4. Depress release button on the quick-release axle and insert through the wheel bearings

with axle spacer resting against the outside wheel bearing.

5. Depress release button and insert quick-release axle into receiver on axle plate until the

wheel assembly rests against the receiver.

6. If the locking balls do not protrude past the receiver, turn the lock nut counter-clockwise

with wrench to increase grip length. If there the wheel is loose and there is too much

play in along the axle, turn the lock nut clockwise to reduce grip length.

7. Replace hubcap by turning it counter clockwise with wheel stationary.

8. Repeat steps 3 to 8 for other wheel.

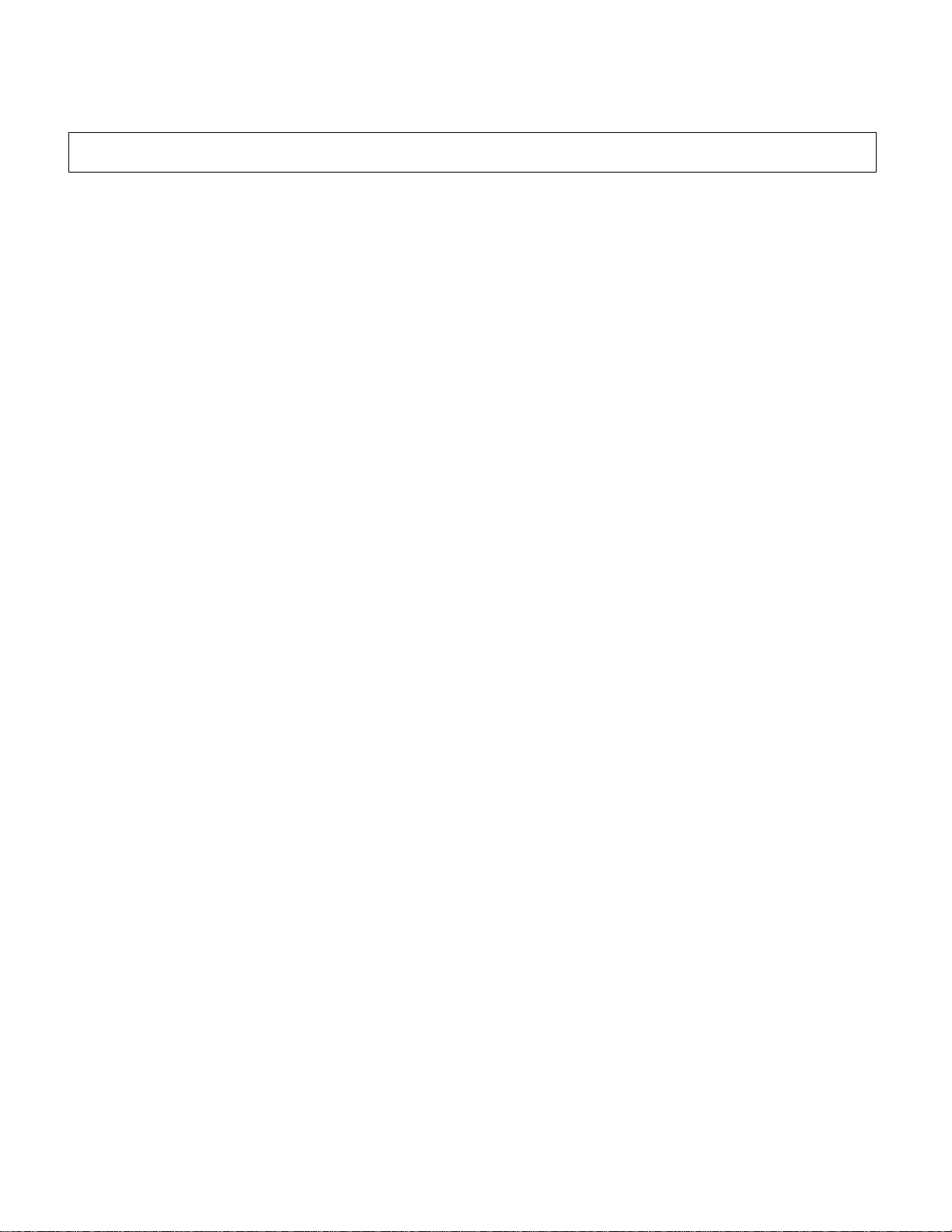

IMPORTANT!

THE LOCKING BALLS ON THE END OF THE QUICK-RELEASE AXLE MUST BE FULLY

OUT, PROTRUDING PAST THE INSIDE OF THE AXLE RECEIVER FOR A POSITIVE LOCK

WHEN THE RELEASE BUTTON IS NOT ACTIVATED. PULL OUTWARD ON THE WHEEL

ASSEMBLY HUB TO ENSURE THE QUICK-RELEASE AXLE IS LOCKED IN PLACE

BEFORE OPERATING THE CHAIR.

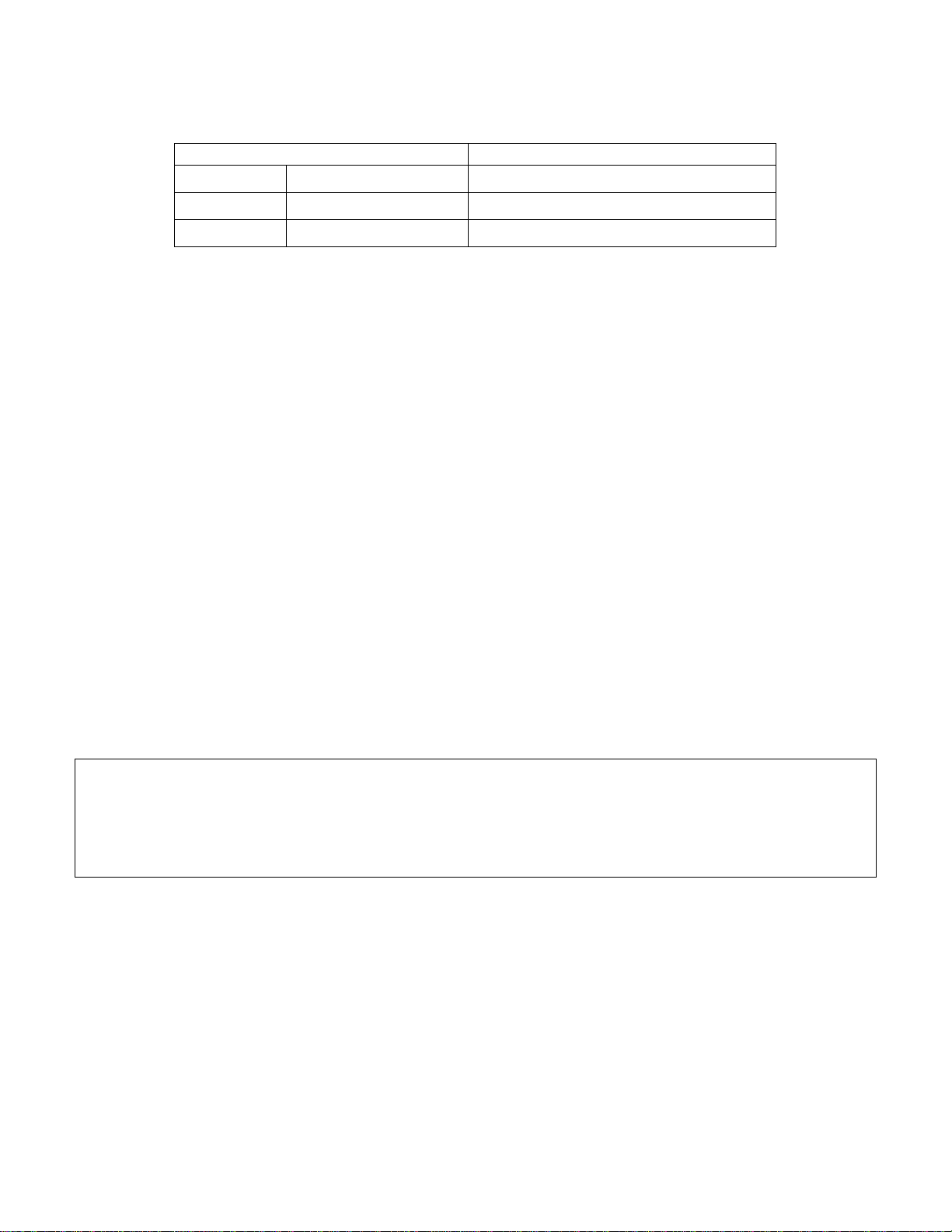

Wheel Lock Installation – SP Model

Tools needed: 4.5mm hex key

1. Remove wheel locks from inner accessory box.

2. Loosen both hex socket cap screws on each clamp.

3. Position the clamp onto the upper frame tube with socket head screws facing up and

strike lever is towards the wheel assembly.

4. Slide the clamp and wheel lock assembly along the tube and until it firmly engages the

tire and stops the wheel from turning when the wheel lock lever is pushed down into it’s

locked position.

TIP: Snug up the hex socket cap screws before activating the wheel lock lever.

5. Tighten both hex socket cap screws on the clamp.

6. Repeat steps 2 to 5 for other wheel lock assembly.