8375 Installation Instructions (Continued)

NOTE: All RCI electromagnetic locks must be powered with filtered

and regulated DC power supplies such as the RCI 10 Series UL

Listed power supply. RCI offers a full line of power supplies and

switching devices that are suitable for use with the 8375 Series

locks.

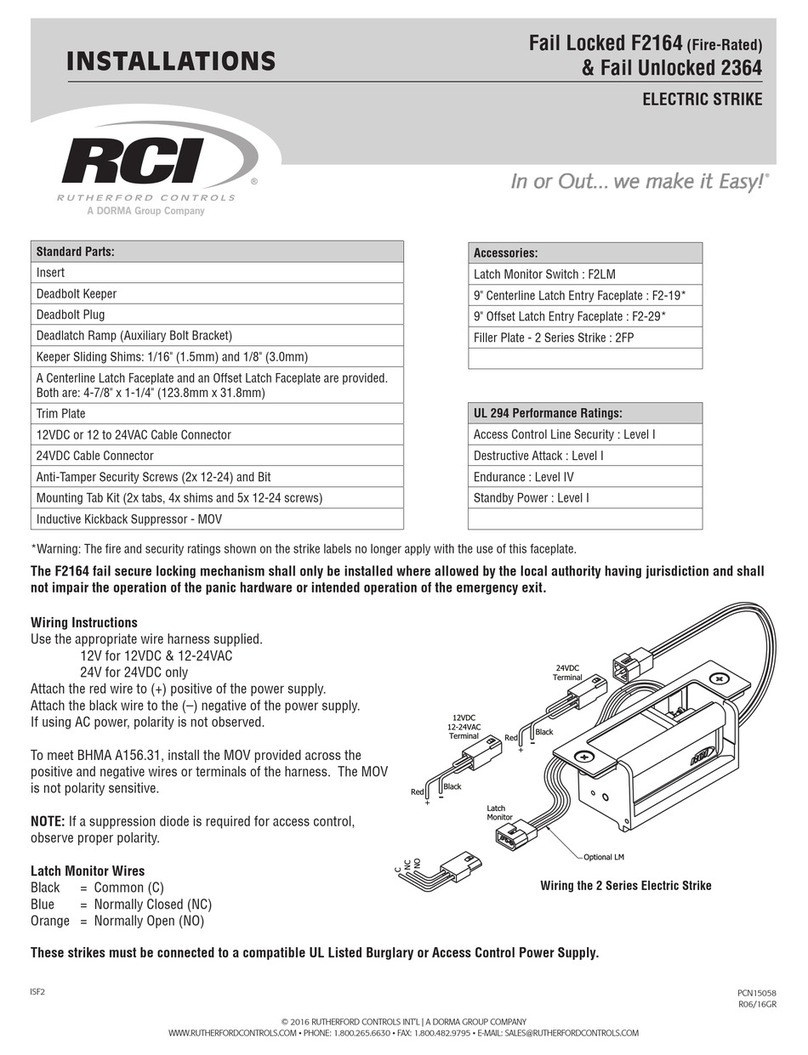

To Ensure Instant Release All switching devices must be wired in

between the DC power source and the positive terminal of the lock

in Fig 3.

Switching the negative power supply line will not allow the lock to

release immediately. RCI electromagnetic locks contain MOV's for

surge suppression and do not require any additional suppression

to be added during installation. The installation of diodes across

the lock input terminals will cause a delay in release.

Fig. 3 – Power Connections

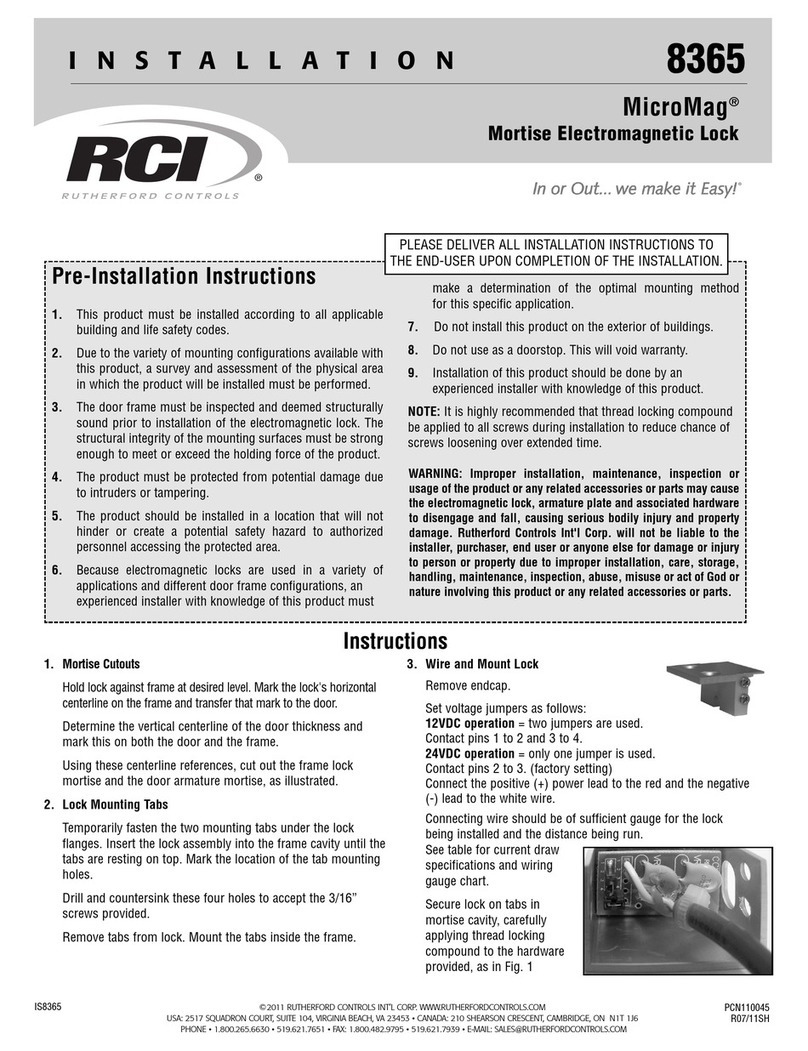

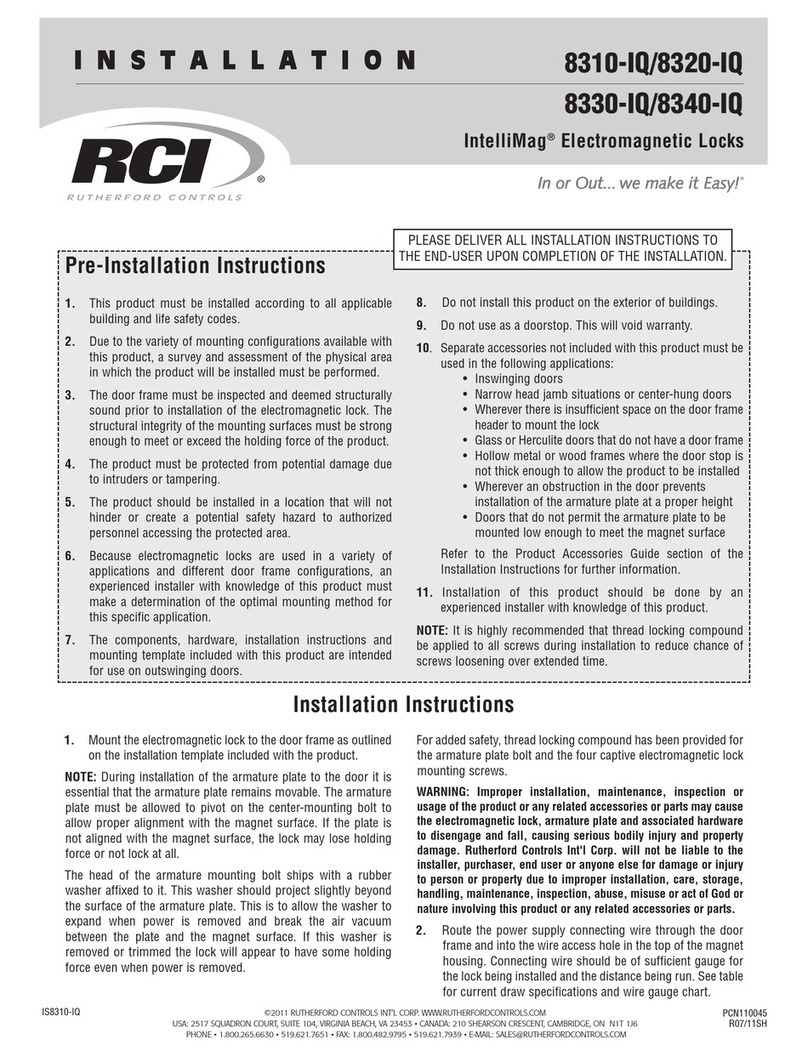

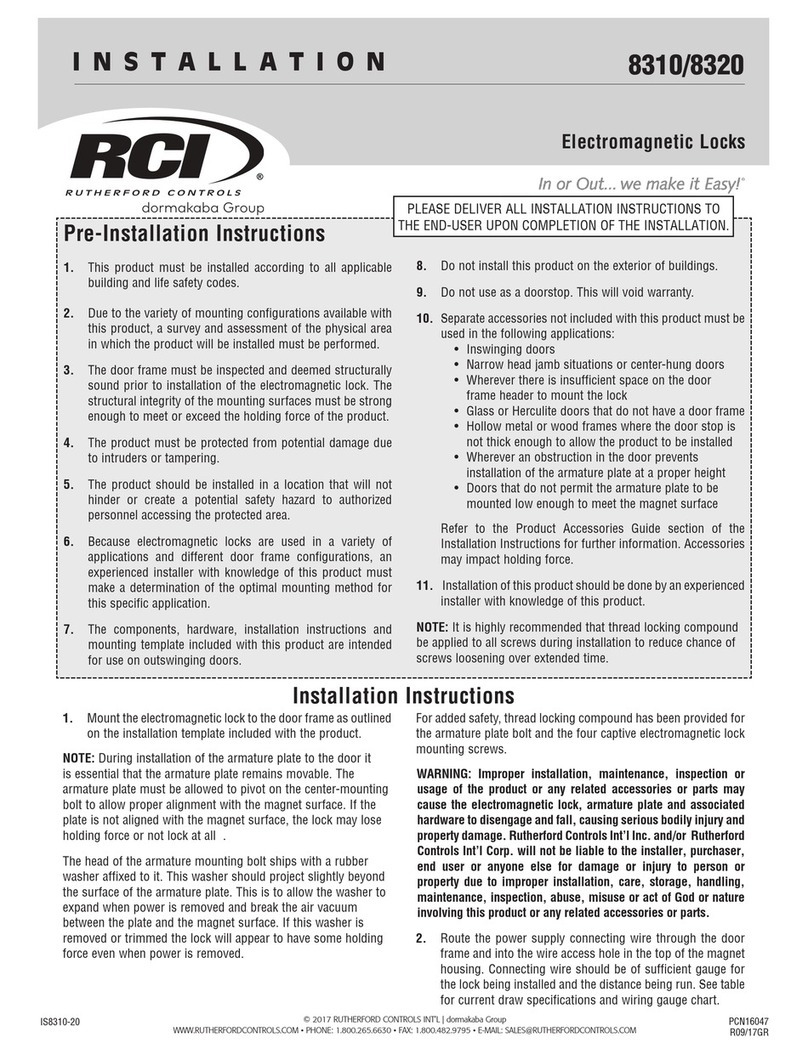

Mount the electromagnetic lock to the door frame as outlined on the

installation template included with the product.

NOTE: During installation of the armature plate to the door it is

essential that the armature plate remains movable. The armature plate

must be allowed to pivot on the center-mounting bolt to allow proper

alignment with the magnet surface. If the plate is not aligned with the

magnet surface, the lock may lose holding force or not lock at all.

The head of the armature mounting bolt ships with a rubber washer

affixed to it. This washer should project slightly beyond the surface

of the armature plate. This is to allow the washer to expand when

power is removed and break the air vacuum between the plate and

the magnet surface. If this washer is removed or trimmed the lock

will appear to have some holding force even when power is removed.

For added safety, thread locking compound has been provided for the

armature plate bolt and the four captive electromagnetic lock mounting

screws.

WARNING: Improper installation, maintenance, inspection or usage of

the product or any related accessories or parts may cause the

electromagnetic lock, armature plate and associated hardware to

disengage and fall, causing serious bodily injury and property

damage. Rutherford Controls Int'l Corp. will not be liable to the

installer, purchaser, end user or anyone else for damage or injury to

person or property due to improper installation, care, storage,

handling, maintenance, inspection, abuse, misuse or act of God or

nature involving this product or any related accessories or parts.

Route the power supply connecting wire through the door frame and

into the wire access hole in the top of the magnet housing. Connecting

wire should be of sufficient gauge for the lock being installed and the

distance being run. See table for current draw specifications and wire

gauge chart.

Installation Instructions

Inspection and Maintenance

This product and all related accessories or parts must be

inspected and maintained on a quarterly basis. Contacting

surfaces of the electromagnetic lock and armature plate must be

kept free of contaminating materials. Surfaces must be cleaned

periodically with a non-abrasive cleaner.

All mounting fasteners must be inspected on a quarterly basis.

When properly installed, the ends of the armature plate allow a

slight movement but the plate will feel secure when grasped at the

bolt. There should be no movement to the mounting bracket or

housing of the electromagnetic lock.

For added safety, thread locking compound has been provided for

the armature plate bolt and the four captive electromagnetic lock

mounting screws.

WARNING: Improper installation, maintenance, inspection or

usage of the product or any related accessories or parts may cause

the electromagnetic lock, armature plate and associated hardware

to disengage and fall, causing serious bodily injury and property

damage.

PLEASE DELIVER ALL INSTALLATION INSTRUCTIONS TO

THE END-USER UPON COMPLETION OF THE INSTALLATION.

For product support, parts and ordering information contact:

Rutherford Controls Int’l Corp.

USA: 2517 Squadron Court, Suite 104,

Virginia Beach, VA 23453

Canada: 210 Shearson Crescent

Cambridge, ON N1T 1J6

Phone: 1-800-265-6630 / 1-519-621-7651

Fax: 1-800-482-9795 / 1-519-621-7939

Website: www.rutherfordcontrols.com

2