©2008 RUTHERFORD CONTROLS INT’L CORP. WWW.RUTHERFORDCONTROLS.COM

USA: 2697 INTERNATIONAL PARKWAY, PKWY 5, VIRGINIA BEACH, VA 23452 • CANADA: 210 SHEARSON CRESCENT, CAMBRIDGE, ON N1T 1J6

PHONE • 1.800.265.6630 • 519.621.7651 • FAX: 1.800.482.9795 • 519.621.7939 • E-MAIL: SALES@RUTHERFORDCONTROLS.COM

7104, 7304 Aluminum & Wood Frames, 1-1/2” D

4104, 4304 Aluminum Frames, 1-1/2” D

Any modular A41, A43, A71 or A73

with B4704 faceplate

MEASUREMENT

FRACTIONAL

INCHES

DECIMAL

INCHES

METRIC

mm

A1-1/4 1.250 31.75

B 4-7/8 4.875 123.83

C3-3/8 3.375 85.73

D 7/8 .875 22.23

E 3/8 .375 9.53

F 1/8* .125* 3.18*

G 1-11/16 1.688 42.86

Vertical Vertical Vertical

XC/LC/L C/L

Door Door Door

R 5/32 .156 3.97

K4-1/8 4.125 104.78

M12-24†——

Vertical Centerline

of Door**

INSTALLATION

Electric Strikes

4/7 Series

7105, 7305 Aluminum & Wood Frames, 1-1/2” D

4105, 4305 Aluminum & Wood Frames, 1-1/2” D

Any modular A41, A43, A71 or A73

with B4705 faceplate

IS47A PCN080047

P10/08DA

MEASUREMENT

FRACTIONAL

INCHES

DECIMAL

INCHES

METRIC

mm

A 1-1/8 1.125 28.58

B 5-7/8 5.875 149.23

C3-3/8 3.375 85.73

D7/8 .875 22.23

E 1/4 .250 6.35

F 1/8* .125* 3.18*

G 1-11/16 1.687 42.86

Vertical Vertical Vertical

X C/L C/L C/L

Door Door Door

R 5/32 .156 3.97

K 5-3/8 5.375 136.53

M12-24†——

Vertical Centerline

of Door**

1. Determine the vertical centerline of the door lock face and

the horizontal centerline of the latch.

IMPORTANT: When determining the horizontal centerline

observe the following:

FOR MORTISE LOCKS: Align the angled ramps of the lip

bracket with the deadlock trigger of the mortise latch.

FOR CYLINDRICAL LOCKS: Align the center of the latch with

the center of the strike opening.**

2. Transfer both the horizontal and vertical centerlines to the

doorframe.**

3. Prepare the doorframe for cutting as per the appropriate

drawing.

4. If required, install “no weld” mounting brackets as per the

instructions included with the mounting brackets in the

hardware pack.

5. Attach the strike insert (coil unit or “motor”) to the lip

bracket with the screws provided.

6. Attach the strike faceplate to the lip bracket with the screws

provided. (It may be desirable to leave these screws slightly

loose to facilitate insertion into the doorframe.

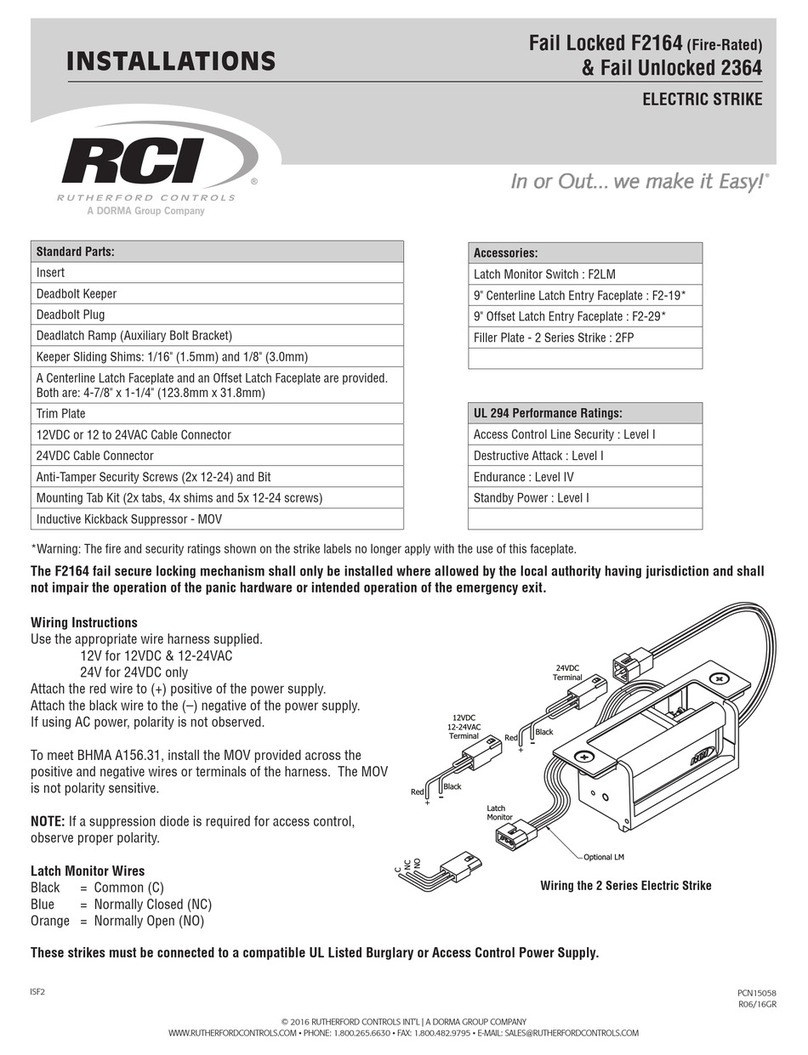

7. Connect the incoming wiring from the power supply to the

terminal screws on the strike insert. RCI door strikes are not

polarity sensitive although be certain to observe proper

polarity if a suppression diode is required for access control

applications.

8. Install the door strike in the doorframe using the screws

provided.

Instructions

NOTE: Specifications subject to change without notice.

*Dimension F is measured from face of mounting tab to face of frame and equates to the thickness of the frame material.

**Dimension X on the drawing is determined by the vertical centerline of the door. If the latch incorporates a deadlocking pin additional steps will be

necessary to ensure proper operation of the deadlocking pin. Measure the thickness of the deadlocking pin and add this thickness to Dimension X to

relocate the vertical centerline an appropriate distance on the frame.

†For wood frame door installations, substitute #12 wood screws for dimension M.

4 & 7 Series Troubleshooting

Latch or keeper are not

functioning properly

Confirm that the keeper is closing properly and that the lever in

the strike cavity is operating freely.

SolutionPossible CausesProblem

Strike will not lock or

unlock properly

No power to the insert Using a multimeter, confirm that you have the correct output

voltage at the power supply.

Using a multimeter, confirm that you have the correct input

voltage at the strike.

Confirm that all connections are tight and secure.

Incorrect voltage used Confirm that the insert and power supply are the proper voltage.

Strike is binding Confirm that the strike keeper functions when the door is open. If

the strike operates correctly, adjust door or strike to eliminate any

backpressure.

Confirm that the strike cavity depth is compatible with the lock

set.

Strike releases but

won’t buzz

Improper power supply Replace the power supply with a correct voltage AC power supply,

and the 12V connector. If this cannot be done, a DC piezo buzzer

can be installed.

Strike makes a buzzing

sound

Improper power supply Replace the power supply with a correct voltage DC power supply.

Insert has a burnt smell Improper voltage Confirm that you have the correct output voltage at the power supply.

Improper application A strike connected to an AC power supply will buzz unless a

rectifier is installed.

Improper installation Confirm that the correct connector was used when installing the

strike 12V for 12VDC & 12-24VAC, 24V for 24VDC only.

Confirm that all connections are tight and secure.

Mortise lock not dead

latching

Improper Installation Check alignment of dead latch and lip bracket ramp.

Door has sagged Adjust door alignment.

Cylindrical deadlatching not

working

Improper Installation /

Door has warped

Adjust the strike horizontal adjustment. (See Installation

Instructions).

Door won’t latch Door has warped or sagged

creating excessive back

pressure

Re-align door in frame or replace.

Monitor switch is not

functioning

Short in wiring Confirm that all connections are tight and secure.

Using a multimeter confirm continuity of the N/O & N/C sides of

the switch.

1.

2.

3.

4.

5.

6.

7.

8.

©2008 RUTHERFORD CONTROLS INT’L CORP. WWW.RUTHERFORDCONTROLS.COM

USA: 2697 INTERNATIONAL PARKWAY, PKWY 5, VIRGINIA BEACH, VA 23452 • CANADA: 210 SHEARSON CRESCENT, CAMBRIDGE, ON N1T 1J6

PHONE • 1.800.265.6630 • 519.621.7651 • FAX: 1.800.482.9795 • 519.621.7939 • E-MAIL: SALES@RUTHERFORDCONTROLS.COM