Trimec ES8000 V-LOCK User manual

IMPORTANT NOTE:

V-Lock must only be used in weather protected areas.•

V-Lock can be installed vertically or horizontally.•

For• vertical mounting, ensure V-Lock is oriented right side up as indicated by the unit label.

For• horizontal mounting, ensure V-Lock is only installed above the door.

For ideal operation, a• door gap of 3mm to 8mm is required between lock unit and strike plate.

Ensure strike plate is flush-mounted or recessed, well-supported and securely fastened to increase overall holding force and•

security of installation.

INSTALLATION INSTRUCTIONS

ES8000 V-LOCK

P

age

1

DRAWINGS NOT TO SCALE. INFORMATION IN THIS DATASHEET MAY BE CHANGED WITHOUT NOTICE.

P

age

4

SPECIFICATIONS

An ASSA ABLOY Group brand

DA0076, Issue 8: 13 May 2008

LOCK MODE CONFIGURATION

STEP 3

- Change jumper position on Printed

Circuit Board beneath the red

re-sealable sticker as shown below:

Power-to-Open

(Fail Secure)

Power-to-Lock

(Fail Safe)

STEP 2

- Rotate Latch Plate screw beneath

the red re-sealable sticker according to

orientation shown below:

Turn counter-clockwise

180ofor Power-to-Open

(Fail Secure)

Turn clockwise 180ofor

Power-to-Lock (Fail Safe)

STEP 1

- Loosen both screws on side of lock

body.

- Slide screws in direction required until

stop at end of slot is reached.

- Hold in position and re-tighten screws.

PTL

PTO

If the lock had been installed or previously operated, the latch plate screw (STEP 3) may not be visible. To•

change lock mode configuration, contact your distributor for additional instructions.

Ensure all re-sealable stickers and screws are re-attached after configuration to prevent ingress of dust.•

5 Year Limited Warranty

ASSA ABLOY Australia guarantees for a period of 5 years in accordance with Trimec’s Standard Warranty Conditions, against defects in

manufacture, workmanship or materials, provided that all electrical and mechanical installation requirements are adhered to as per this

datasheet. All third party and consequential claims are expressly excluded from this warranty.

warranty ASSA ABLOY Australia

2/16 Atkinson Road

Taren Point 2229

NSW, Australia

www.assaabloyasiapacific.com

Parameter Specification

Door Gap Between 3mm to 8mm only

Lock Monitor Output Voltage free changeover switch contacts rated for 48vDC / 100mA

Holding Force AS4145.2 - 1993: Passed S3 (611kg for 1 minute)

Capable of 1000kg if strike plate is fully supported

Release under Side Load 15kg max at bolt with motorised unlocking (3 wire control)

3kg max at bolt with Power-To-Lock (Fail Safe) unlocking and 2 wire control

Bolt Dimensions Diameter = 11mm

Projection = 20.5mm

Power Supply (12-28VDC) Regulation better than +/- 2%

1Amp Power supply required

Current Draw Power to Lock holding current 130mA

Power to Open holding current 30mA

Initial locking and unlocking current draw higher

Misalignment tolerance +/- 3.5mm

Operating Temperature -10oC to +50oC at 90% RH

Durability > 300,000 cycles

Certifications 2-hour fire rating

WITH 30MM FACEPLATE

Page

2

P

age

3

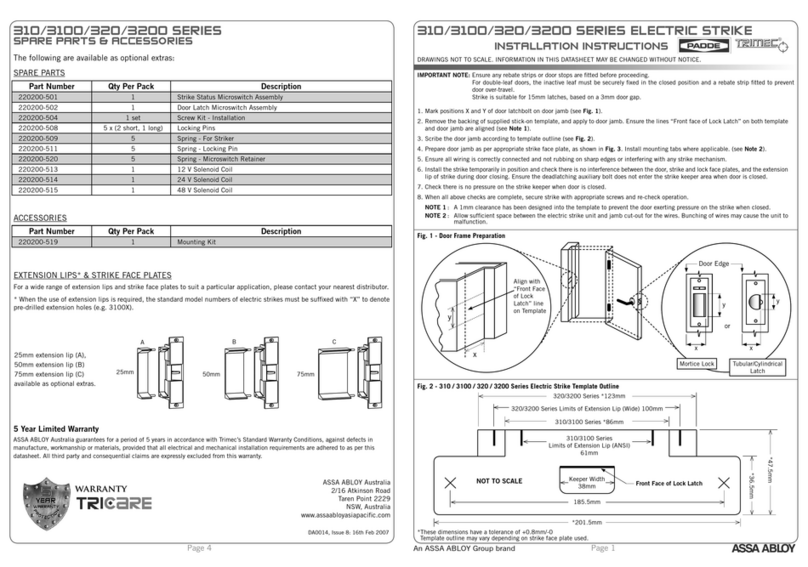

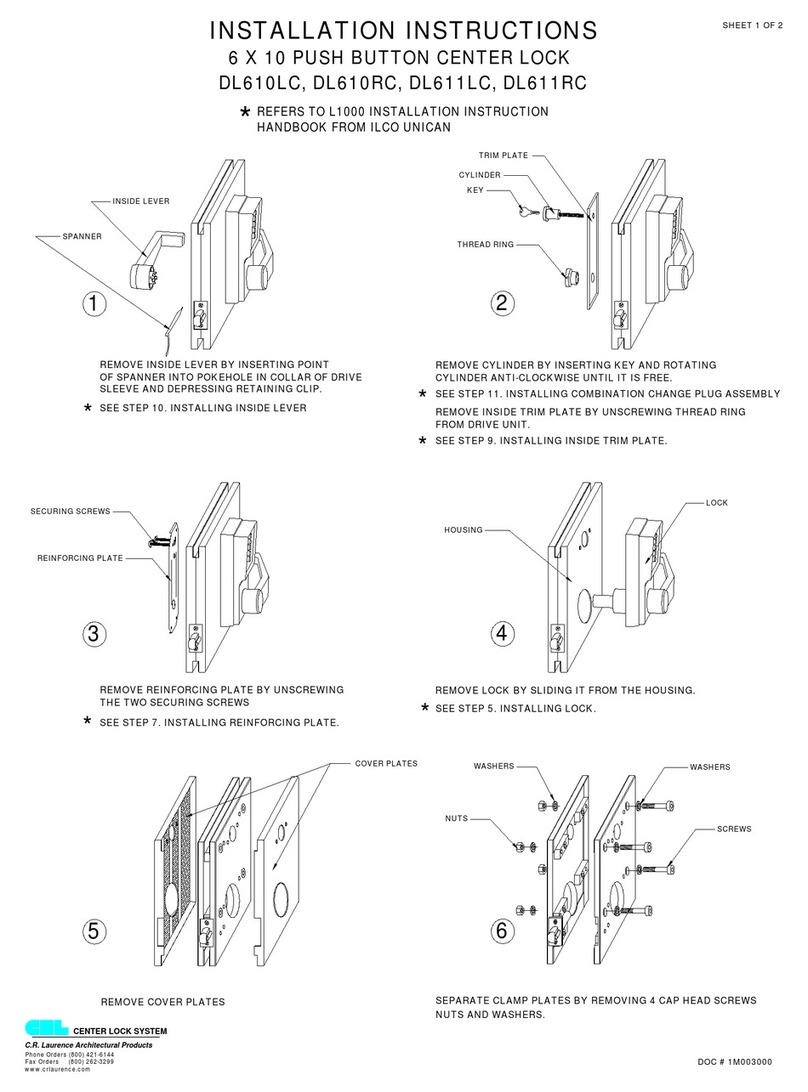

Mark LINE 1 corresponding to mid-plane of door (see1. Fig. 1).

On door jamb, mark LINE 2 which will be in line with LINE 1 (see2. Fig. 2).

Mark cutout of V-Lock symmetrically about LINE 2. Cutout size must be 256mm x 30mm. Thickness of strike plate and lock3.

faceplate are 3mm each. Prepare door jamb appropriately as shown in Fig. 2.

Ensure all wiring is correctly connected and not rubbing on sharp edges or interfering with any lock mechanism.4.

Install lock unit into door jamb as shown in5. Fig. 3.

On the door, mark LINE 3 corresponding to the top edge of lock faceplate (see6. Fig. 1). Mark and recess cutout of strike plate

on door symetrically about LINE 1, and using LINE 3 as reference.

Install strike plate on door, and ensure that door gap between strike plate and lock faceplate is between 3mm and 8mm7.

only (see Fig. 3).

Power up lock, then let door open and close normally with door closer. When strike plate magnet comes within locking range,8.

the V-Lock unit will lock as long as lock bolt closes within target locking range (see Detail A).

Fig. 1 - Door Preparation

For locking bolt on V-Lock unit to attempt locking, strike plate magnet MUST be correctly aligned and in•

front of the M mark on the lock faceplate. Lock will not operate without strike plate.

Fig. 2 - Door Jamb Preparation

Detail A - Target Locking Range

If door closes outside target locking range (+/- 3.5mm), V-Lock will execute 5 locking•

attempts.

If lock bolt cannot enter the strike hole after 5 attempts, lock will cease• operation to

prevent motor burn-out.

When this happens, adjust door closer or re-position strike plate. To restart• locking

sequence, send another door open/close signal to the V-Lock.

Fig. 3 - V-Lock Installation

ELECTRICAL SPECIFICATIONS

The V-Lock is designed to be controlled with a minimum of 3 wires. Positive voltage should be connected to the

RED wire providing permanent power, a second negative wire connected to BLACK and a third positive voltage

wire connected to BLUE providing a lock/unlock signal. When connected with 3 wires the motor will provide

power assisted unlocking allowing the bolt to retract with up to 15kg of side load. Voltage-free changeover

switch contacts are provided for bolt position monitoring. When locked, the monitor switch (COM - PURPLE) is

connected to (NC - ORANGE).

The V-Lock is multi-voltage and operates with either 12 to 24vDC power. It has in-built Reverse Polarity Protection

for installer safety. For a lock in locked position, wiring diagrams for both Power-To-Open (Fail Secure) and Power-

To-Lock (Fail Safe) are found below:

Bolt Position

Monitor

Power To Lock (PTL) Wiring Connections

- Access Control (PTL)

ORANGE

BLACK

BLUE

RED

PURPLE

WHITE

- 0 volts d.c.

- Positive Continuous Supply

- (COM)

- (NO)

- (NC)

-

+

DC Power

NC

NO

Bolt Position

Monitor

Power To Open (PTO) Wiring Connections

ORANGE

BLACK

BLUE

RED

PURPLE

WHITE

- 0 volts d.c.

- Access Control (PTO)

- Positive Continuous Supply

- (COM)

- (NO)

- (NC)

NC

NO

-

+

DC Power

In Power-To-Lock (Fail Safe) configuration, it is possible to operate the V-Lock using 2 control wires only. With 2 wire control

the lock relies on the Fail Safe spring mechanism to unlock, which reduces the lock’s capability to open under side load to only

3kg. Hence, 2 wire control is NOT RECOMMENDED and should be avoided wherever possible.

For retrofit applications where only 2 control wires may exist, connect the BLUE and RED wires on the lock together and join

them to the positive supply voltage. Connect the negative supply voltage to the BLACK wire on the lock (see below).

Bolt Position

Monitor

Power To Lock 2 Wire Control - NOT RECOMMENDED

ORANGE

BLACK

BLUE

RED

PURPLE

WHITE

- 0 volts d.c.

- (COM)

- (NO)

- (NC)

-

+DC Power

256

Strike Plate

3mm Thickness

7

48

242

24132

D22 x 20 Deep

27

Door

LINE 3

LINE 1

(Half thickness of door)

M

Lock

Faceplate

256 1515

30

30

256

50

24

42

210

Door Jamb

LINE 2

Magnet

Maximum door gap

3mm - 8mm

Strike Plate

V-Lock Unit Door Jamb

Door

M

Mounting Tabs (supplied)

Required for Flush Mounting only

Magnet and M must line

up for V-Lock to operate

3.5mm

3.5mm

INSTALLATION

Other Trimec Lock manuals