7

4 ESTABLISHING SERIAL COMMUNICATIONS

4.1 IMPORTANT WARNING BEFORE SENDING COMMANDS

Some serial commands can affect the analogue output and limit relays. If the E725 is

being used in a control application, carefully consider the implications of sending RS232

commands.

4.2 Serial Communications Protocol.

Refer also to sections 2 & 3.

Baud rate The E725 baud rate is selectable. See section 2.2 for details of

how to find the current setting. The default value is 9600

Parity = NONE

Start bits = 1

Stop bits = 1

Number of data bits = 8

4.3 Establishing RS232 Communications.

Please follow these steps in order to verify serial communication.

a) Turn off both the E725 and the host device (PC, PLC etc)

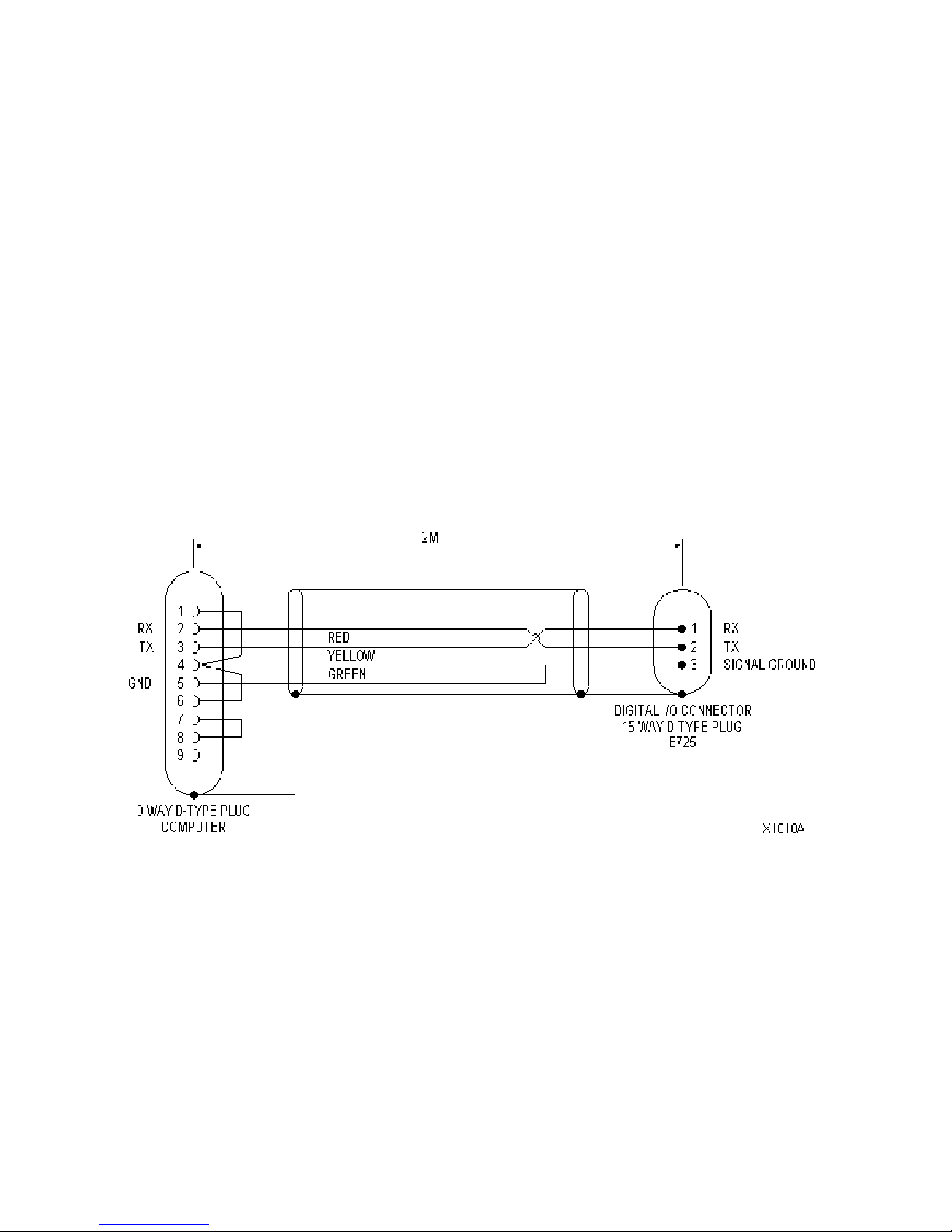

b) Connect the two devices using a lead wired as detailed in section 3.1.

c) Turn on both the E725 and the host computer.

d) Start a serial communications program on the host computer. It is strongly

recommended that a terminal emulation program is used, rather than any high level

software. We recommend Microsoft Terminal for windows 3.1, or a similar program.

e) Configure the terminal software with the correct serial communications protocol and

baud rate, as detailed in section 4.2.

f) Type '#00 sys'* and press the enter key. The E725 should respond with a short line

of identification text, including the unit part number and software version. If this

happens, communication has been successfully established.

* This assumes that the module address is the default value of '00'

See section 7 for faultfinding information.

4.4 Establishing RS485 communications.

Note. The E725 units must have the optional factory fitted RS485 option. See sect 2.

a) Turn off both the E725 and the host device (PC, PLC etc)

b) Connect ONE of the E725 units to the communications lead, leaving all other sockets

unconnected. Ensure that the RS232/485 converter is connected and turned on.

c) Turn on both the E725 and the host computer.

d) Start a serial communications program on the host computer. Initially a terminal

emulation program should be used, rather than any high level software. We

recommend Microsoft Terminal for windows 3.1, or a similar program.

e) Configure the terminal software with the correct serial communications protocol, as

detailed in section 4.2. The baud rate of the communications program should be set

to that of the E725. See section 2.2 to find out the E725 baud rate setting.

f) Send the following commands.