3

OPERATING INSTRUCTIONS

PROBLEM AND SOLUTION

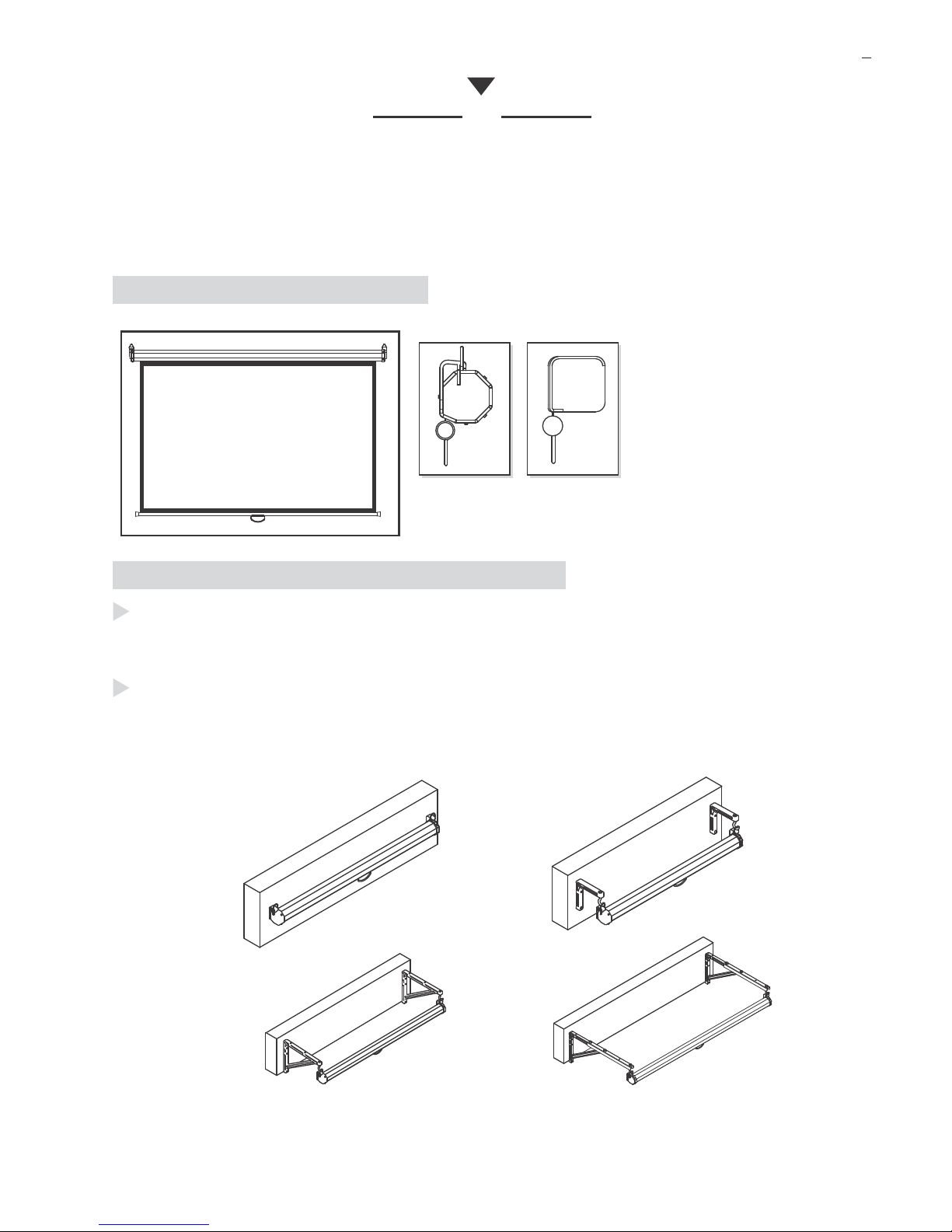

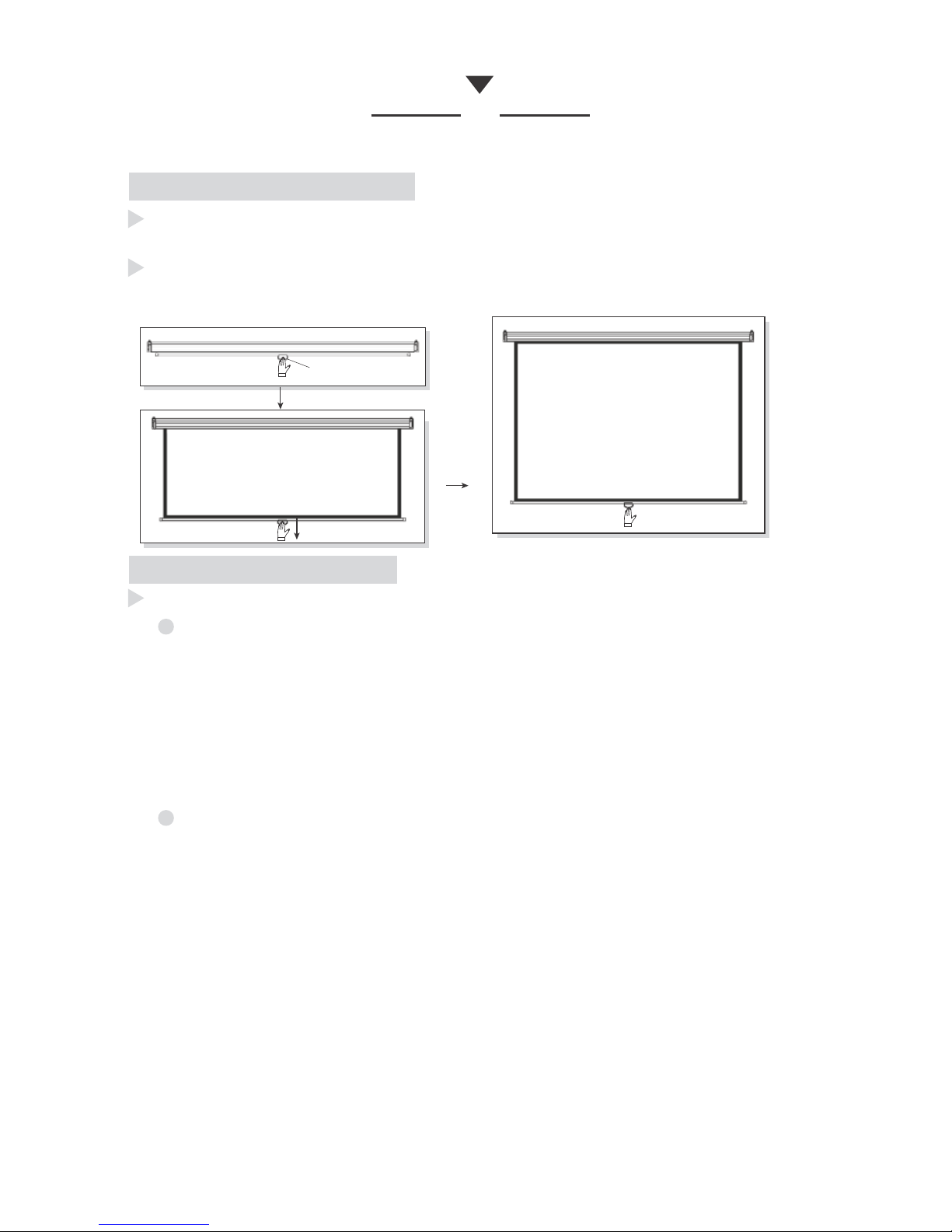

Pull down the screen with the loop (00-15), stop at the desired position

for one second, then release the loop(00-15).

If the screen is not used for a long time, hold the loop (00-15), pull

down SLIGHTLY then release it IMMEDIATELY, the screen will retract

back into the housing.

PROBLEM: The screen does not retract all the way; a small part exposed.

Solution: Tighten the spring one or two turns clockwise.

PROBLEM: The screen will not retract; nearly the entire surface exposed.

Solution: You must fully rewind the spring.

The following problems may occur after a long period of infrequent use.

00-15

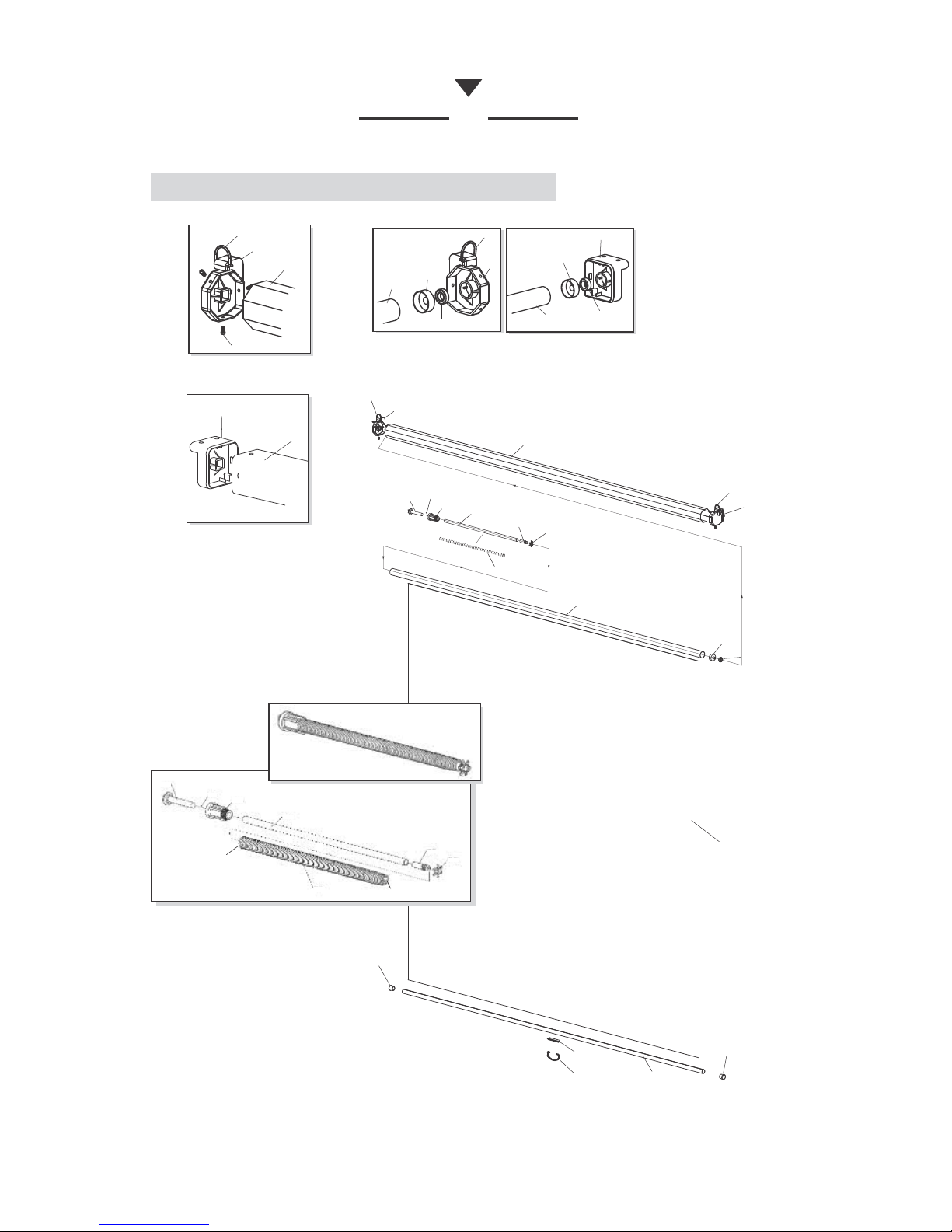

Loosen the three screws in the left end cap (00-01) and pull out the end cap slightly so

that it is disconnected from the housing. NOTE: Be careful to not remove the end cap as

this will allow the spring to unwind. Instead be certain to maintain contact with the end

cap and the lock head (00-04). The lock head fits into the square socket on the inside of

the end cap. With the end cap loose from the housing turn the end cap one or two

revolutions clockwise to tighten the spring.

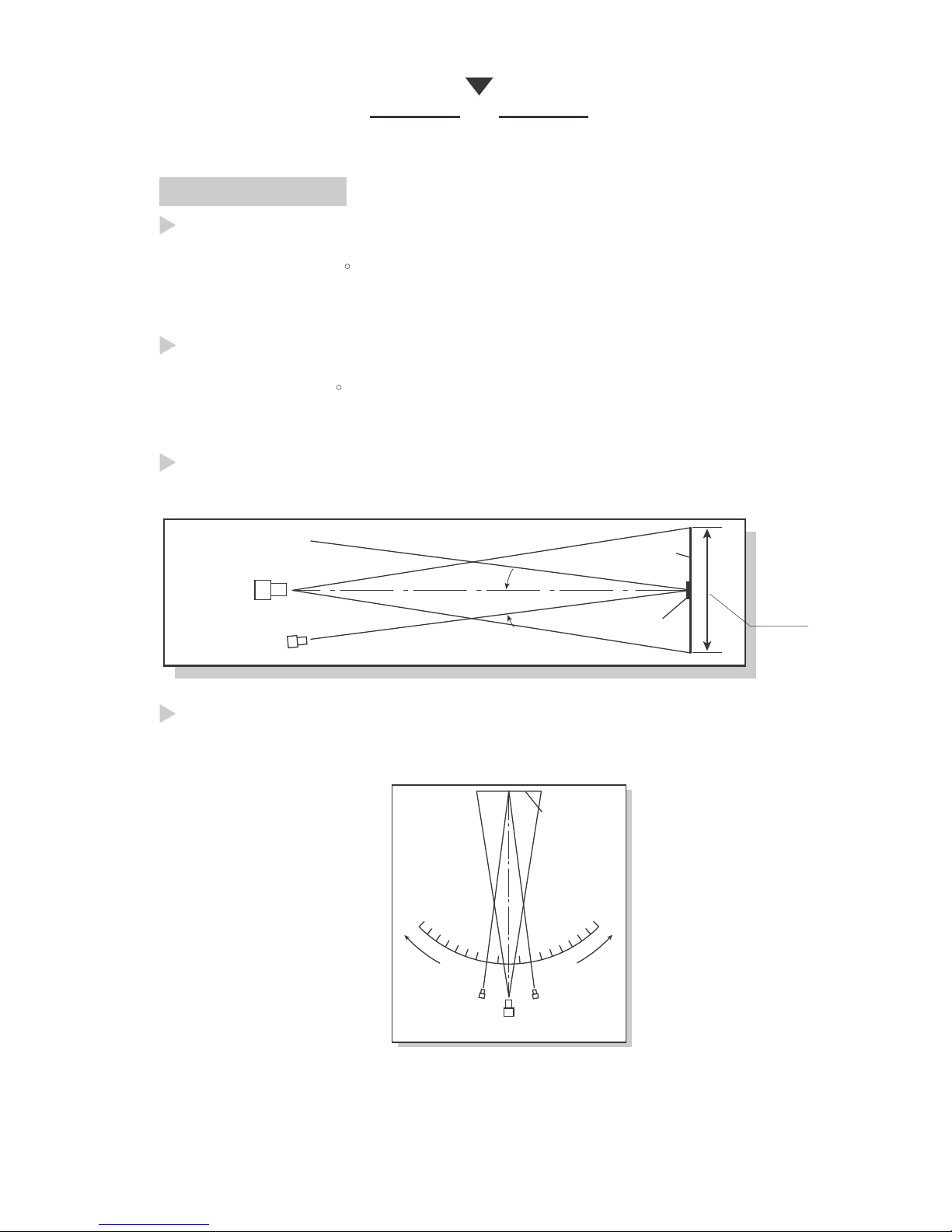

Loosen the three screws in the left end cap (00-01) and completely remove it from the

housing. Next mark the roller (00-10) with a pen where it matches up with the small

triangle marking on the lock-head (00-04), and then remove the lock-head from the roller.

This will allow the spring to fully unwind. Now put the lock-head back into the roller and

match up the mark you made with the triangle mark on the lock-head. Next, align the end

cap so that the hanging ring (00-16) is oriented up and place the end cap back onto the

lock-head. Note, that the triangle mark on the lock-head will be pointing up in the same

direction as the hanging ring. Now you are ready to rewind the spring. Turn the end cap

clockwise to tighten the spring. Refer to the table on the next page for the proper number

of turns for your screen size. When finished winding the spring fasten the end cap to the

housing. Also, refer to Figure 1 and Figure 2 on the next page for diagrams to helps

clarify this procedure.