Ref.: RX182/010

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 1 / 24

Summary: English version

1INTRODUCTION 2

1.1 WARNINGS 2

1.2 GEARBOX IDENTIFICATION 2

1.3 LONG TERM STORAGE 2

2TECHNICAL DATA 3

2.1 GEARBOX 3

2.2 OUTPUT PINION 3

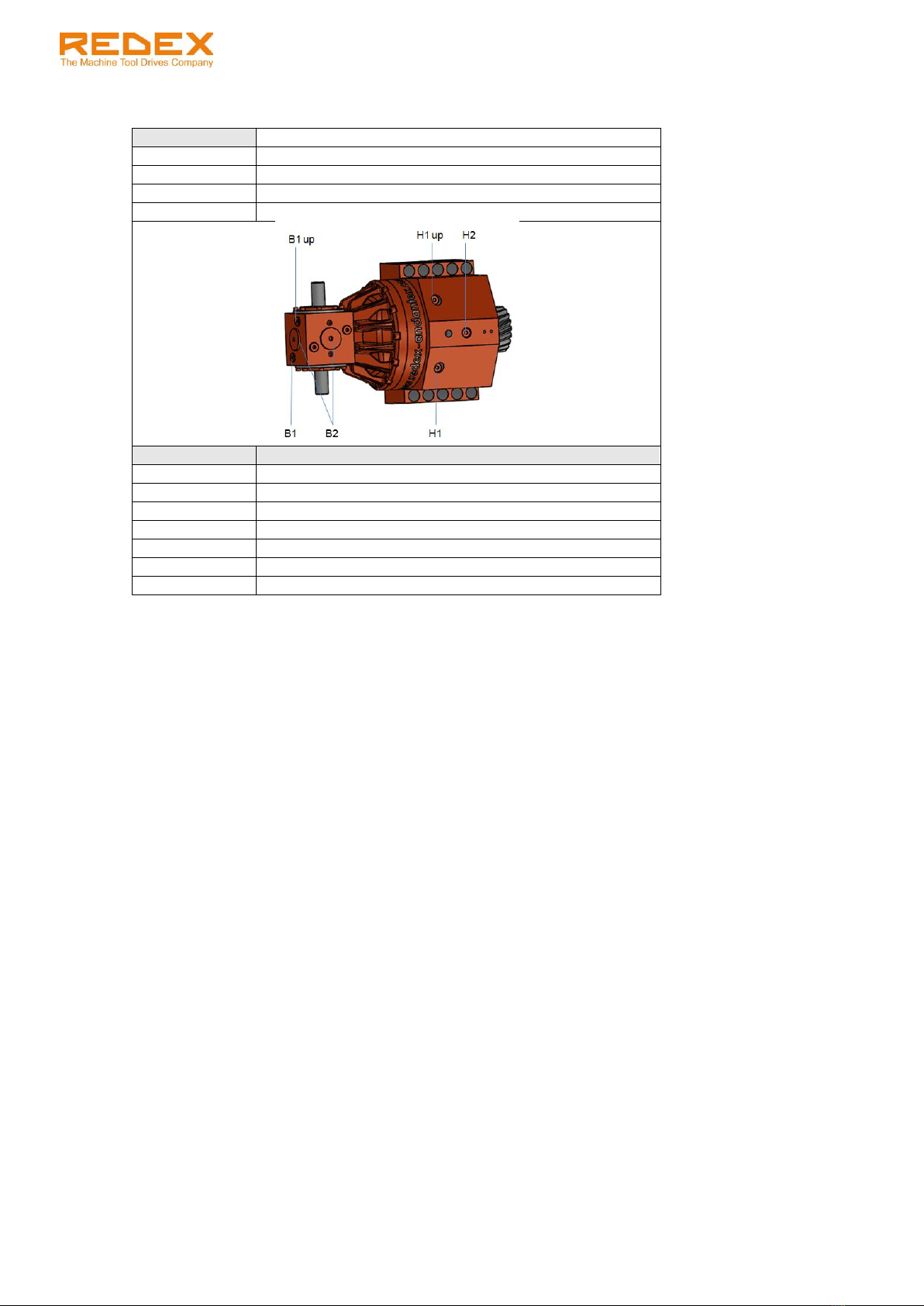

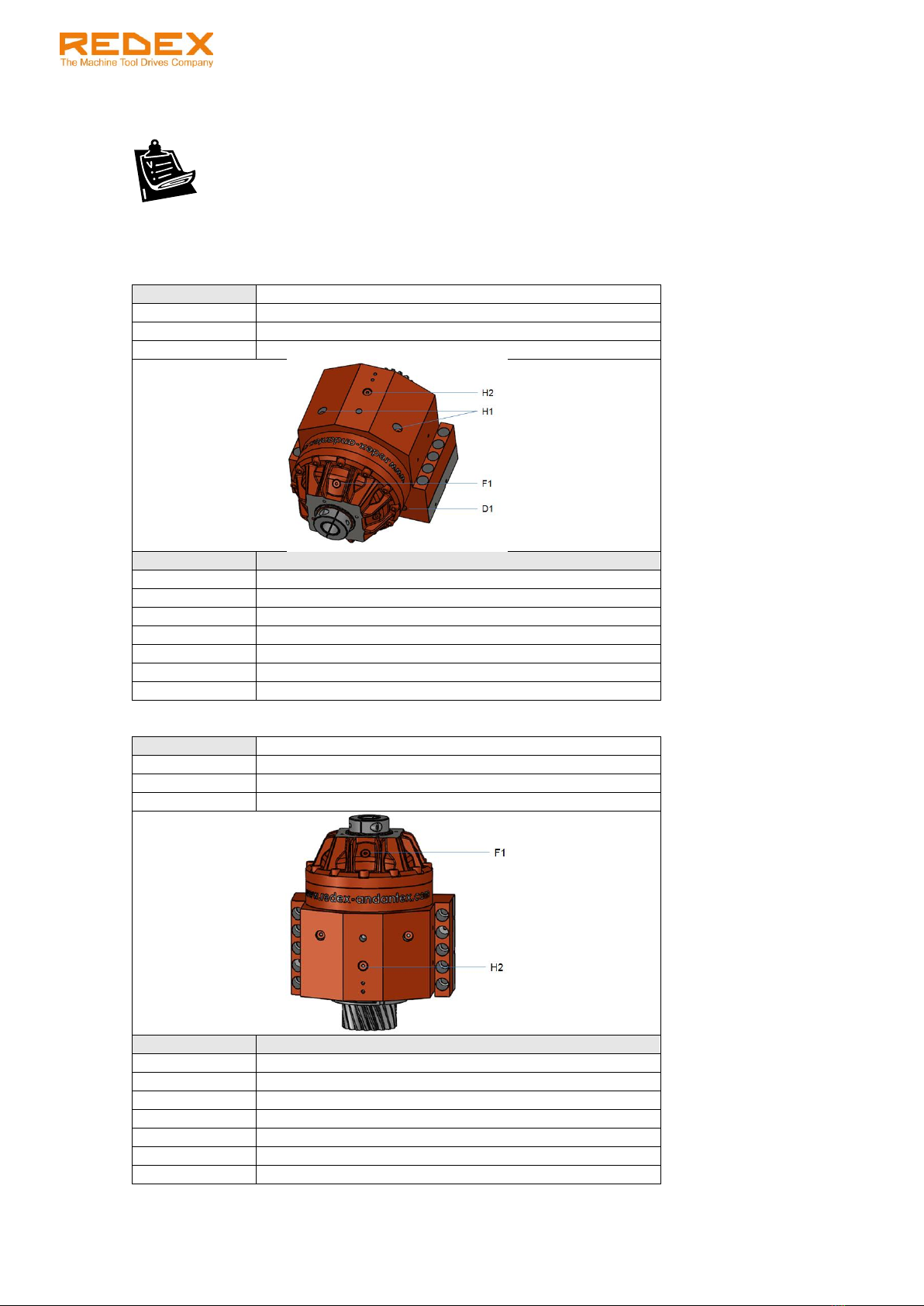

2.3 MOUNTING POSITION NOMENCLATURE 3

3LUBRICATION 4

3.1 RECOMMENDED LUBRICANTS 4

3.2 OIL FILLING:RIGHT-ANGLE CONFIGURATION (KRPX+R) 4

3.3 OIL FILLING:MOTOR IN-LINE CONFIGURATION (KRPX+M) 8

3.4 OIL DRAINING 10

4INSTALLATION ON THE MACHINE 11

4.1 RACK MOUNTING TOLERANCE 11

4.2 KRPX+ PERPENDICULARITY TOLERANCES 12

4.2.1 SET UP DATA 12

4.2.2 SET UP METHOD 12

4.3 KRPX+ HEIGHT SETTING 13

4.3.1 SET UP DATA 13

4.3.2 SET UP METHOD 15

4.4 PROPER TOOTH MESHING VALIDATION 16

4.5 TOOTH CONTACT PATTERN CHECK 17

4.6 KRPX+ FINAL FIXING 17

4.7 INSTALLATION IN CASE OF ROTARY DRIVE 18

5MOTOR INSTALLATION 19

5.1 MF-TYPE MOTOR FLANGE MOUNTING (FOR RIGHT ANGLE CONFIGURATIONS KRPX+R AND CYLINDRICAL SHAFTS) 19

5.2 MF-TYPE MOTOR FLANGE MOUNTING (FOR RIGHT ANGLE CONFIGURATIONS KRPX+R AND TAPER SHAFTS) 20

5.3 IF-TYPE MOTOR FLANGE MOUNTING (FOR IN-LINE CONFIGURATIONS KRPX+M) 21

6RACK & PINION LUBRICATION: OPTIONAL LUBE PINION (PGRP) AND LUBE PINION SUPPORT

(SFRPX) 24

6.1 DESCRIPTION OF THE PGRP &SFRP OPTIONS 24

6.2 RECOMMENDED LUBRICANTS 24

6.3OIL FLOW RATES 24