3

! SAFETY INSTRUCTIONS !

Fig. 1

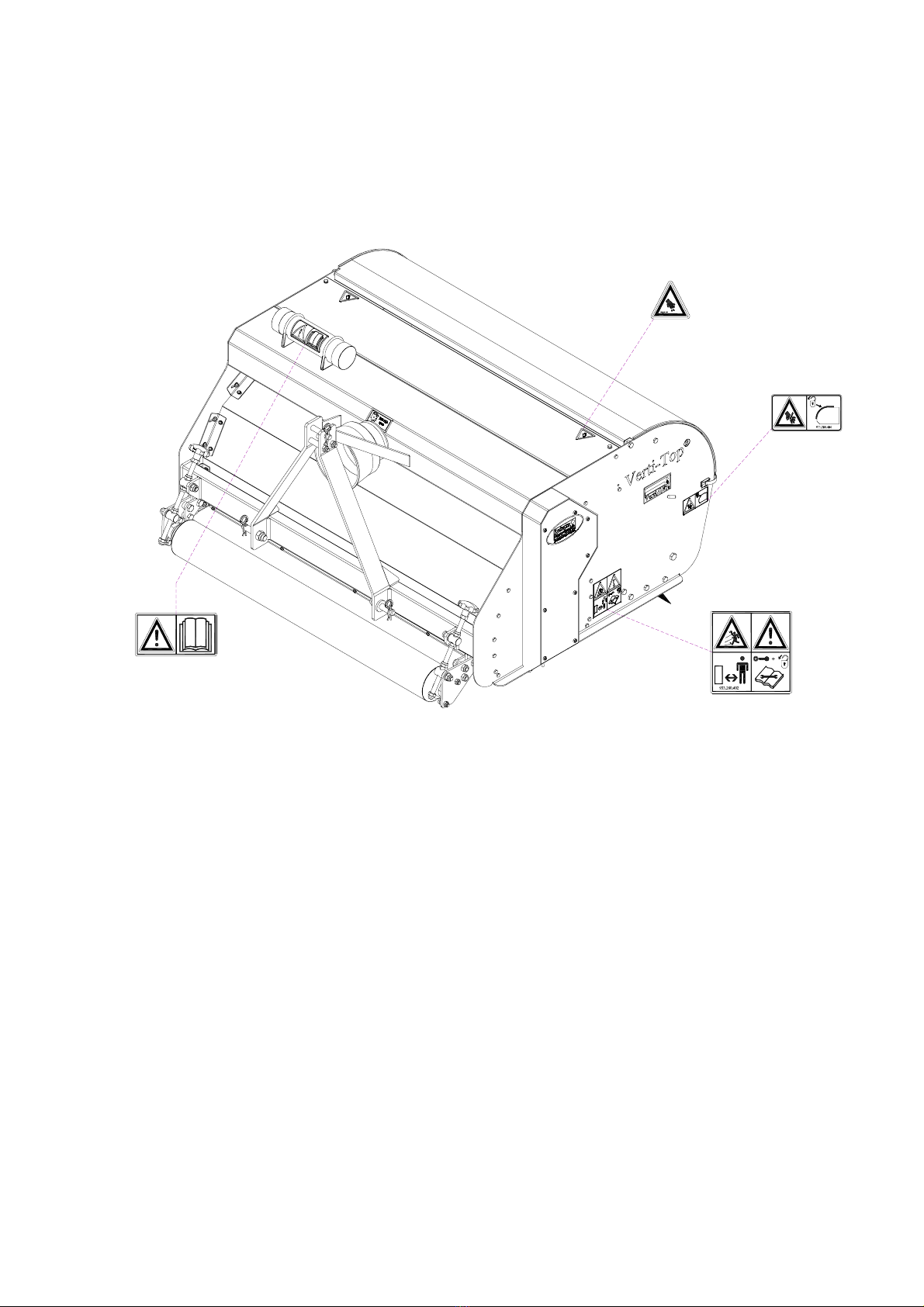

The design of the Verti-Top allows for safe use.

However, this is only possible if the user fully

observes the safety instructions given in this

manual.

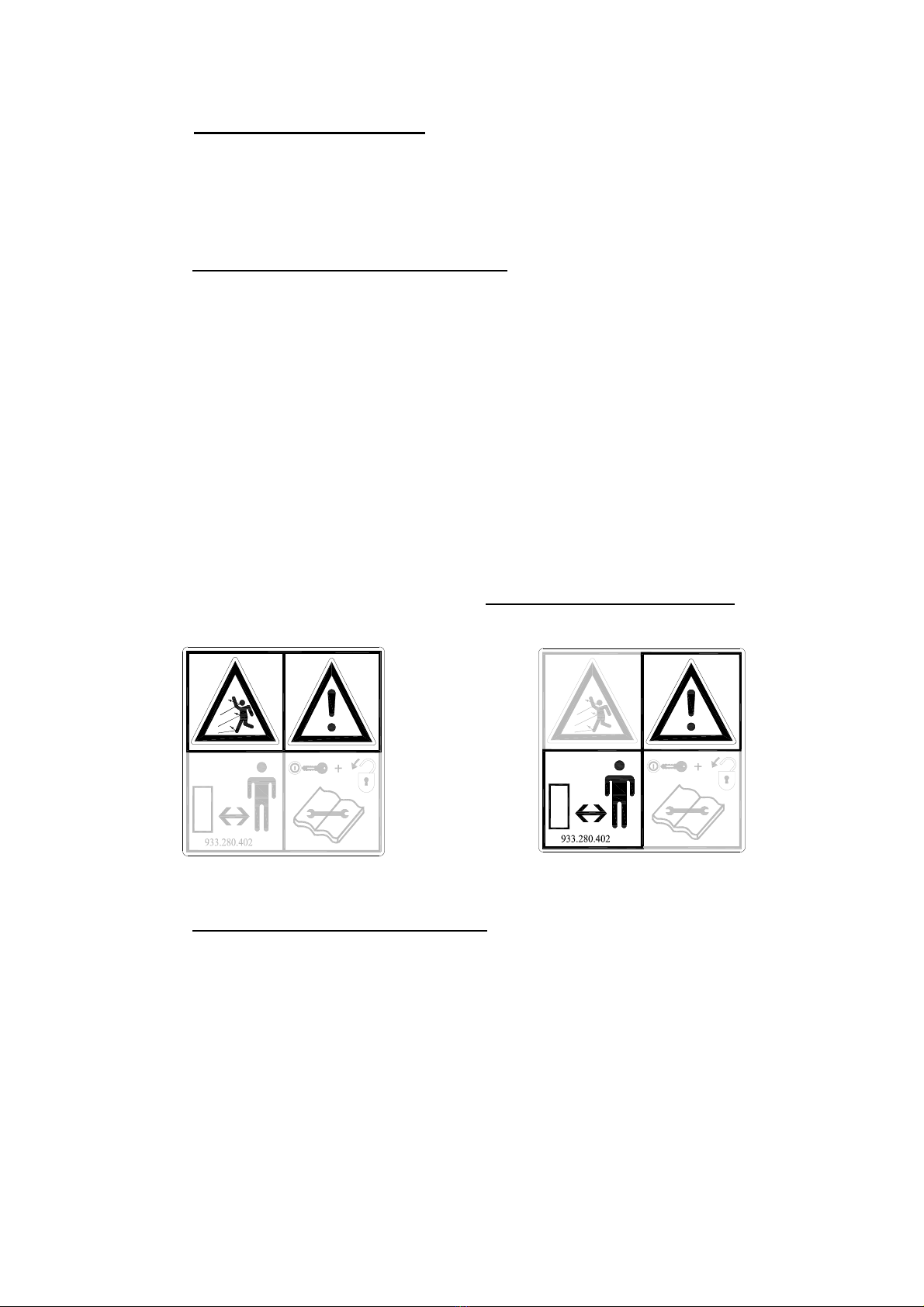

Read and understand (Fig. 1) the manual before

starting to use the Verti-Top.

If the machine is not used as described in the

manual, injury and/or damage to the Verti-Top

may result.

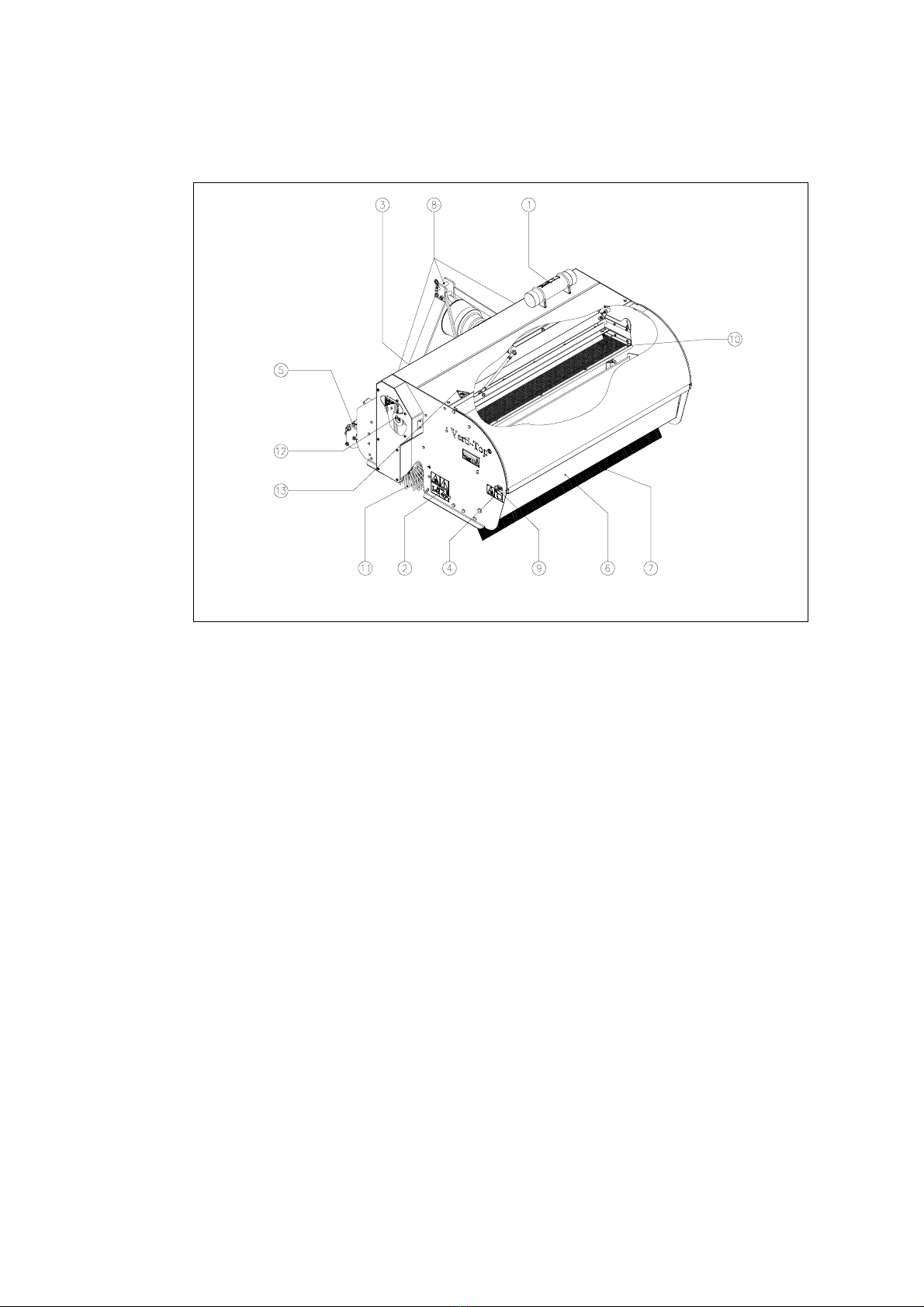

(1) The machine must only be used by professionals and must first be professionally

adjusted for use on the ground that is to be treated.

The manufacturer does not accept any liability with regard to damage resulting

from non-professional use; all resulting risks are the responsibility of the user.

Correct/professional use also includes following the manufacturer’s instructions

for use, maintenance and repair.

Before using the Verti-Top, inspect the area to be treated.

Remove any loose obstacles and avoid irregularities.

(2) The Verti-Top was constructed according to the latest technological knowledge

and is safe to use.

Improper use, maintenance or repair of the machine may result in injury to both

the user and others. This should be avoided!

Always use the Verti-Top in combination with the proper tractor as described in

the technical data.

(3) All persons whom the owner assigns to operate, maintain or repair the Verti-Top

must read and have completely understood the operating manual and in particular

the section Safety Instructions.

The user is responsible for a safe tractor/Verti-Top combination. This unit

must be tested in terms of noise, safety and ease-of-use. In addition, user’s

instructions must be prepared.

(4) Before using the Verti-Top, the user is obliged to inspect it for visible damage and

defects.

Any changes in the Verti-Top (including its functioning) that may affect its safety

must be corrected immediately.

For reasons of safety, it is in principle forbidden to make changes in or additions

to the Verti-Top (with the exception of those approved by the manufacturer).