ADJUSTMENTS

AND

TESTING

FS700 B – FS800 B

Doc. 10032657

Issued 12/2011

Ver. AA

Pag. 2 di 12

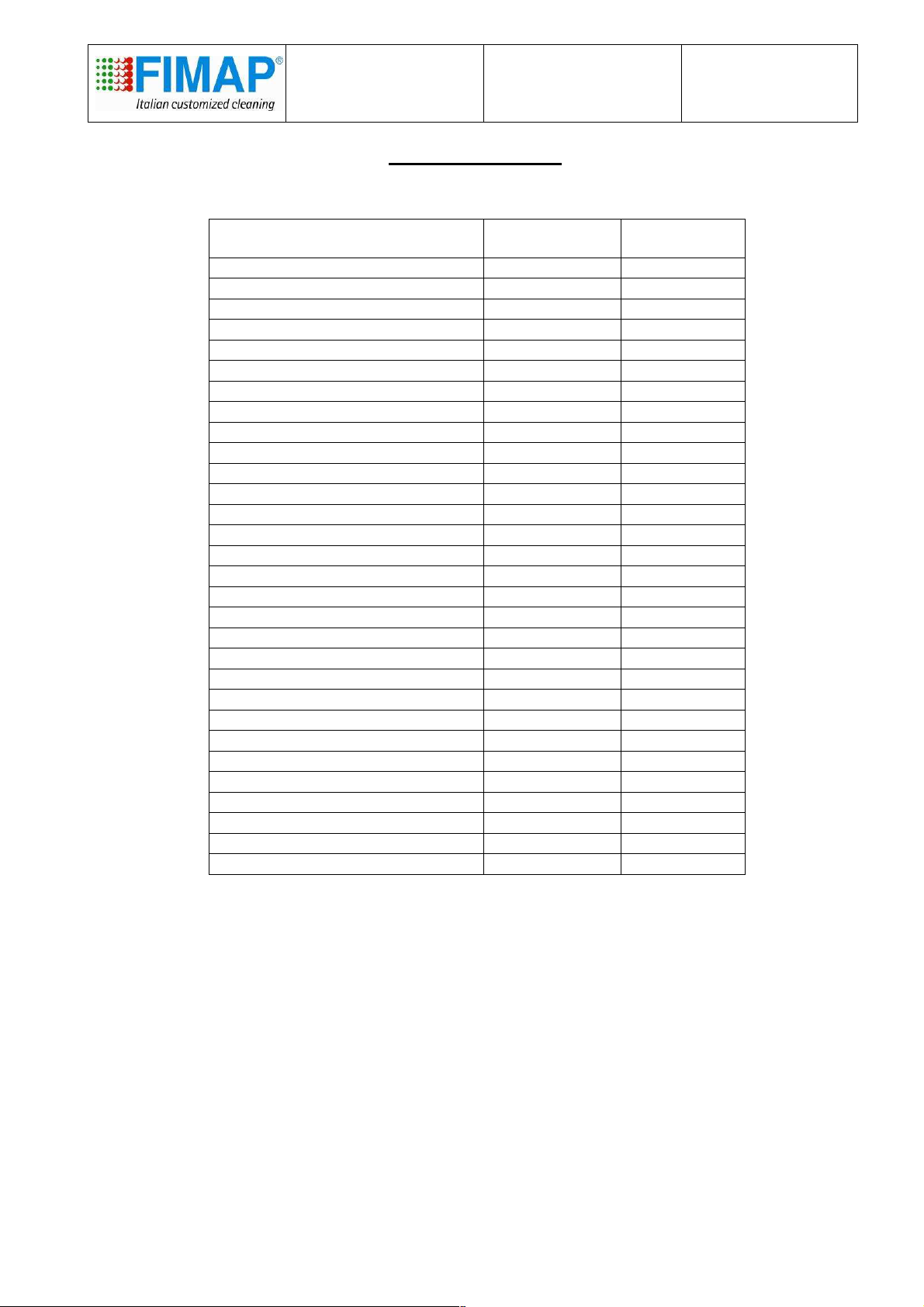

ALARM TABLE

Message Alarm What to do

A ARM A1

FW Switch ON

Forward micro-switch on in

turning on.

Put the potentiometer in idle position and

verify that the forward micro-switch is

open.

A ARM A2

BW Switch ON

Backward micro-switch on

in turning on.

Let the pedal stay in idle position and open

the ackward micro-switch.

A ARM A3

Pot. FAU T Potentiometer error Check the potentiometer harness.

A ARM A4

Ref OUT Neutral

Potentiometer not correclty

positioned

Put the potentiometer in the idle position or

if it already is in the right position, make

the potentiometer programmation.

A ARM A5

Over temperature Thermal protection Wait for 5 minutes and then verify the

traction motor a sorption rate.

A ARM A6

POWER STAGE Damaged power stage Replace the chopper card.

A ARM A7

OVERCURRENT Overcurrent

Check the motor ca les: If connections are

regular and repeat the alarm, replace the

chopper card.

A ARM A8 POWER

FUSE/RE AY

Power fuse or internal

contactor damaged

Check the fuse on the + attery and wiring,

replace the chopper card if it persists

(General relay damaged).

A ARM A9

UNDERVO TAGE Undervoltage Check the atteries for poor voltage.

A ARM A10

OVERVO TAGE Overvoltage Battery voltage greater than 45V: check

attery status

A ARM A11

Overload Current Current protection Check the motor current and possi ly trim

the electronic current control

A ARM A12

DISAB E ON Disa ling active Check the status of the disa led.

A ARM A13

KEY-OFF Turn off sequence active Check the wiring on the ignition power key.

A ARM A14

EEPROM FAI E²prom data reading failed Check the settings: if the alarm is repeated,

replace the chopper card.