42

SCARPAVAPOR®NO LIMITS

ENGLISH

20. The security stopper/security valve must be replaced every 3

years from the rst ignion.

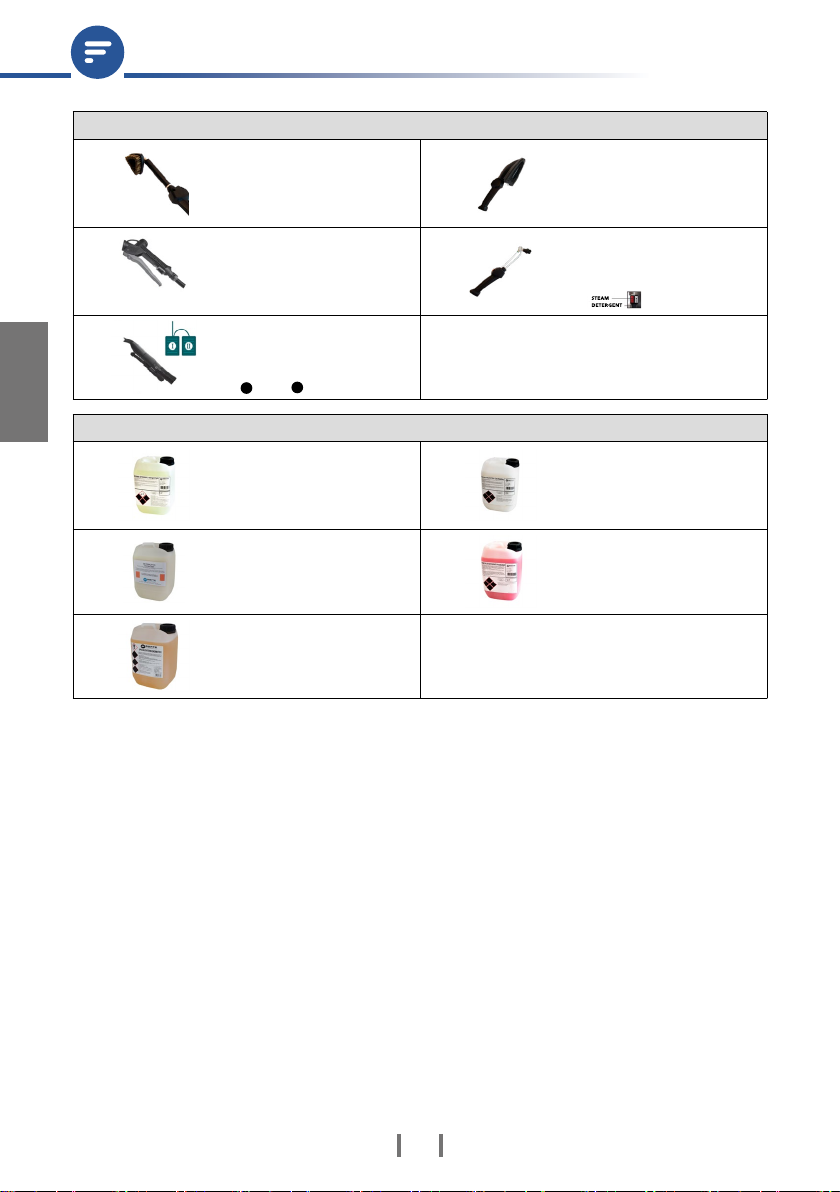

21. With some of our machines, it is possible to dispense detergen-

ts as well. It is recommended not to pour foaming detergents

inside the dedicated tank, the foam might get into the vacuum

motor breaking it up.

22. For all models, do not pour detergents, chemicals, acids, sol-

vents, corrosive or toxic substances, perfumes etc.inside the

boiler, pour only water. Before this operaon verify the machi-

ne is o and unplugged.

23. Do not use the machine to remove dust or corrosive liquids

(acids or bases), inammable and/or explosives.

24. Do not clean the machine by water spraying, do not dip into

water, use only a wet cloth with the machine o, unplugged

and cooled. Do not use any type of detergents.

25. Never touch the machine while plugged with wet hands and/

or barefoot.

26. Do not use the machine next to water (sinks, pools, bathtubs,

containers, etc.), in places with a certain danger of explosion or

presence of toxic/inammable substances.

27. Do not run steam jet towards people and/or animals and

electrical or electronic plugged equipment.

28. Do not push or pull the machine from the steel drum. To move

it use the dedicated handle.

29. Do not pull the steam/water gun hose to move the machine.

30. To perform any maintenance, repair, cleaning work the machi-

ne must be unplugged, cool, and the boiler at “zero” pressure.

31. At the end of every working session unplug the machine then

empty and clean the dirt-gathering steel drum. The emptying

and cleaning of the boiler must be done at least once a month.

Before doing it, unplug the machine, let it cool and gently un-

screw half-round the security valve to remove eventual residual