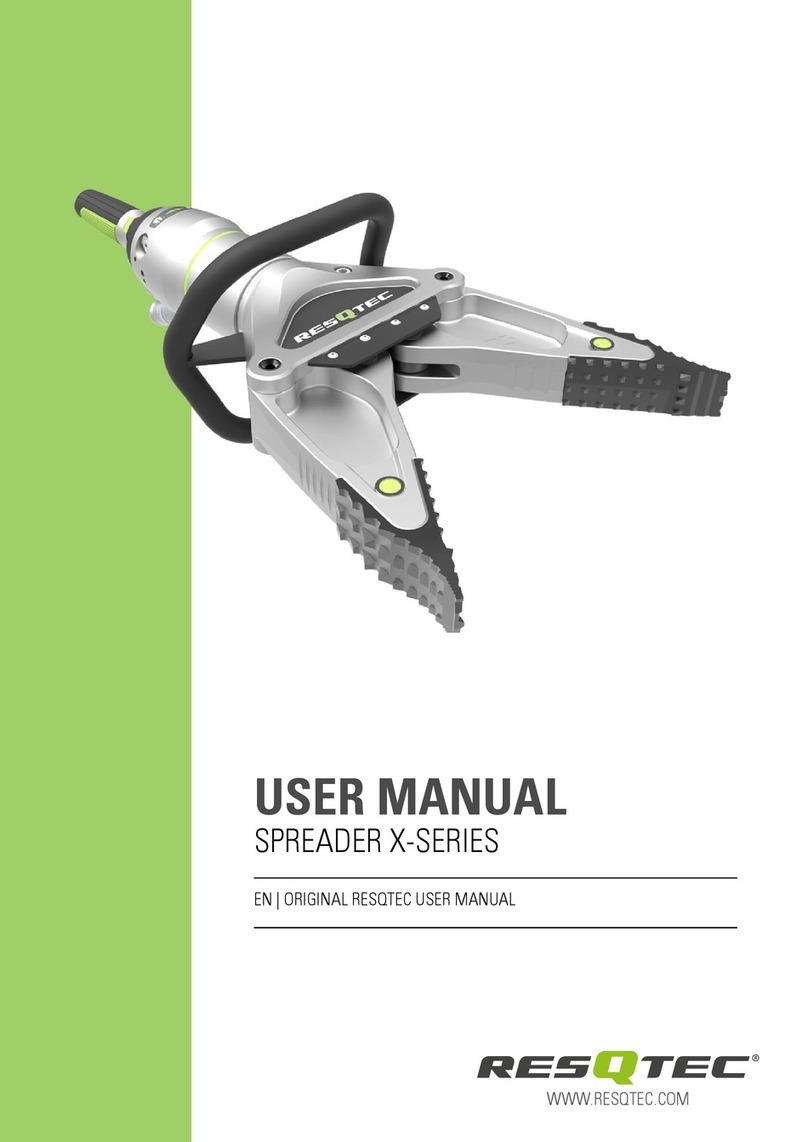

USER MANUAL SPREADER X-SERIES

05

RESQTEC Manual SPREADER X-series (DM064K08)

1.3. SAFETY INFORMATION

Before using the equipment and its related products and accessories, conduct an overall size-up of the intended use and safeguard against

potential hazards before installing the product. Read and understand this manual before using the equipment.

The WARNING and SAFETY labels on the product alert the user to special hazards inherent with its use. Should they

become damaged or unreadable, contact the manufacturer to obtain a replacement.

BEFORE INSTALLING THE PRODUCT, BE AWARE OF THE FOLLOWING:

•Makesurethatnokinkwillforminanyofthehosesduringuse.Makesurethatthehoseprovidesafreeowatalltimes.Failingto

do so may result in damage to the hose assembly and malfunction of your Resqtec system.

• Make sure no one on site is in danger or might get, when using Resqtec equipment. Be aware of your surroundings, the situation you

and the people around you are in, and what the consequences of the use of the Resqtec system are.

• When in use hold the product by the handles.

• NEVER, when in use, hold the product by any of its moving parts. Doing so can result in serious injury.

• NEVER, when in use, place your hands or any other body parts between the moving parts or between the arms/jaws and a

(stationary) object. Doing so can result in serious personal injury.

• When using a Resqtec product, always make sure the object is stable or stabilized by proper cribbing and/or shoring methods.

• Never pull a Resqtec product towards you by the hoses. Pick up the product by the handles instead, as intended.

• NEVER pull a hose to try to untangle it or to free a hose from an obstacle. Always direct your full attention to the problem; clear the

hose from the obstacle or untangle the hose before proceeding.

1.4. PRODUCT IDENTIFICATION

Productidenticationistomakesurethatthismanualcomeswithaspecicproductandthatthismanualshouldalwaysbeavailableasa

reference guide to that equipment. It is mandatory that this manual and accompanying “Service Booklet” are not separated from the product

speciedbelowduringitsservicelife.ThismanualcomeswithResqtecproducttype:

1.5. APPLICABLE TYPES

This manual covers the following product types:

X

Distributor/Supplier information:

With serial number: Hydraulic fluid used in product:

RESQTEC OPTI-GREEN HF-15 BIODEGRADABLE

RESQTEC OPTI-GREEN HF-46 BIODEGRADABLE

SKYDROL (PHOSPHATE ESTER MCS 2361)

ARTICLE NUMBER ITEM DESCRIPTION

4720.0000.** X2

4744.0000.** X4

4760.0000.** X6