77

– the set value is in the range 0 to “PtE“ (max. 80 °C) if water is the heat transfer fluid,

– the set value is in the range 0 to 250 °C if oil is the heat transfer fluid.

With leak-stop mode and oil the max. heating capacity is 60%.

By pressing the key twice, the suction or drainage mode by compressed air (model P140S) mode is

initiated and the consumer connected to the unit is drained. The upper lamp lights up.

Drainage is possible only when the fluid temperature S1 is below the programmed pump run-out tem-

perature “PtE”. If this is not the case, the unit will first cool the heat transfer fluid down to this value.

The pump will then switch off.

After the run-out time “dtP”, the pump will reverse direction and empty the consumer during suction

time “Sut”. After this period of time, the unit will switch off automatically.

Drainage and leak-stop modes can be interrupted by pressing the “On/Off” key. Holding the “On/Off”

key (wait until the “Suction/ Leak-Stop” lamp goes off) will switch the unit back to normal operation.

When using water as the fluid and in leak-stop mode, the set value cannot be adjusted higher than the

“PtE” value.

Note: In pressurized water units, the pressure release valve shuts 5 °C above the “PtE” temperature,

i.e. max. 85 °C, and opens at “PtE” when cooling.

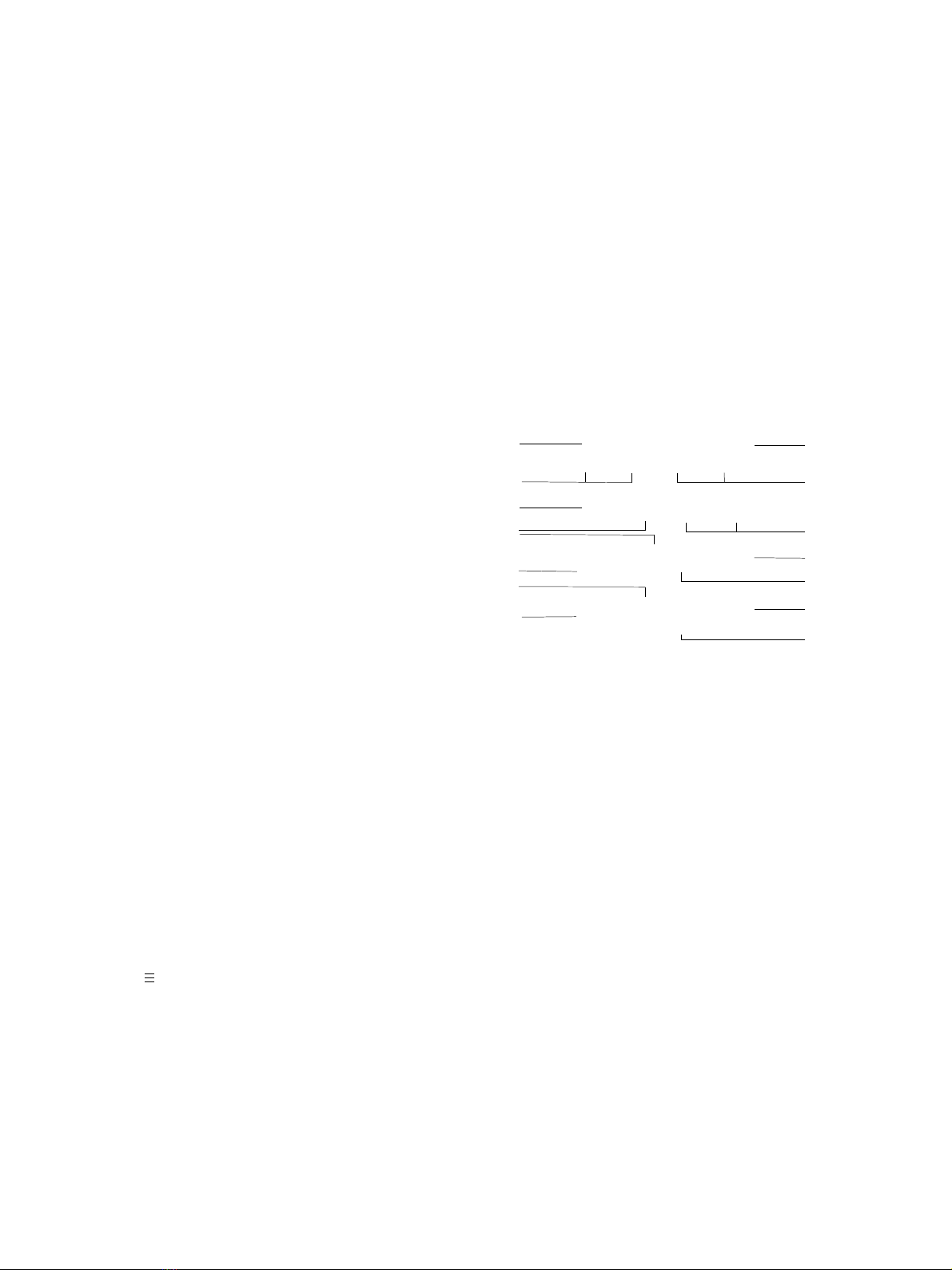

“Alarm Reset” key and switch-over “set value 1” (SP1)/“set value 2” (SP2) with lamp (6). Func-

tion:

– Manual resetting of the alarm relay (e.g. horn switched off). As soon as the malfunction has been

corrected, the alarm display can be switched off by pressing this key once more.

– Manual acknowledgement of the automatic switch-over from consumer temperature control (cas-

cade) to outlet temperature control for defective or missing sensor Sn2 (consumer sensor).

These notes are valid only, if the value «rtr» in Section 7.3 is set to 0.

– Set value switch: pressing the key briefly will cause the second set value SP2 to be displayed and

the “SP2” light to flash.

Pressing the key for 3 seconds will activate the second set value and cause the “SP2” lamp to light.

The display or reactivation of the first set value SP1 will occur accordingly.

The set value can also be activated via an external signal (see Section 6.1, Display 9).

Important: The set value can be switched only when there is no alarm, i.e. the “Alarm Reset” lamp is

not lit.

Programming of the second set value SP2 see Section 7.1, fig. “SP2”.

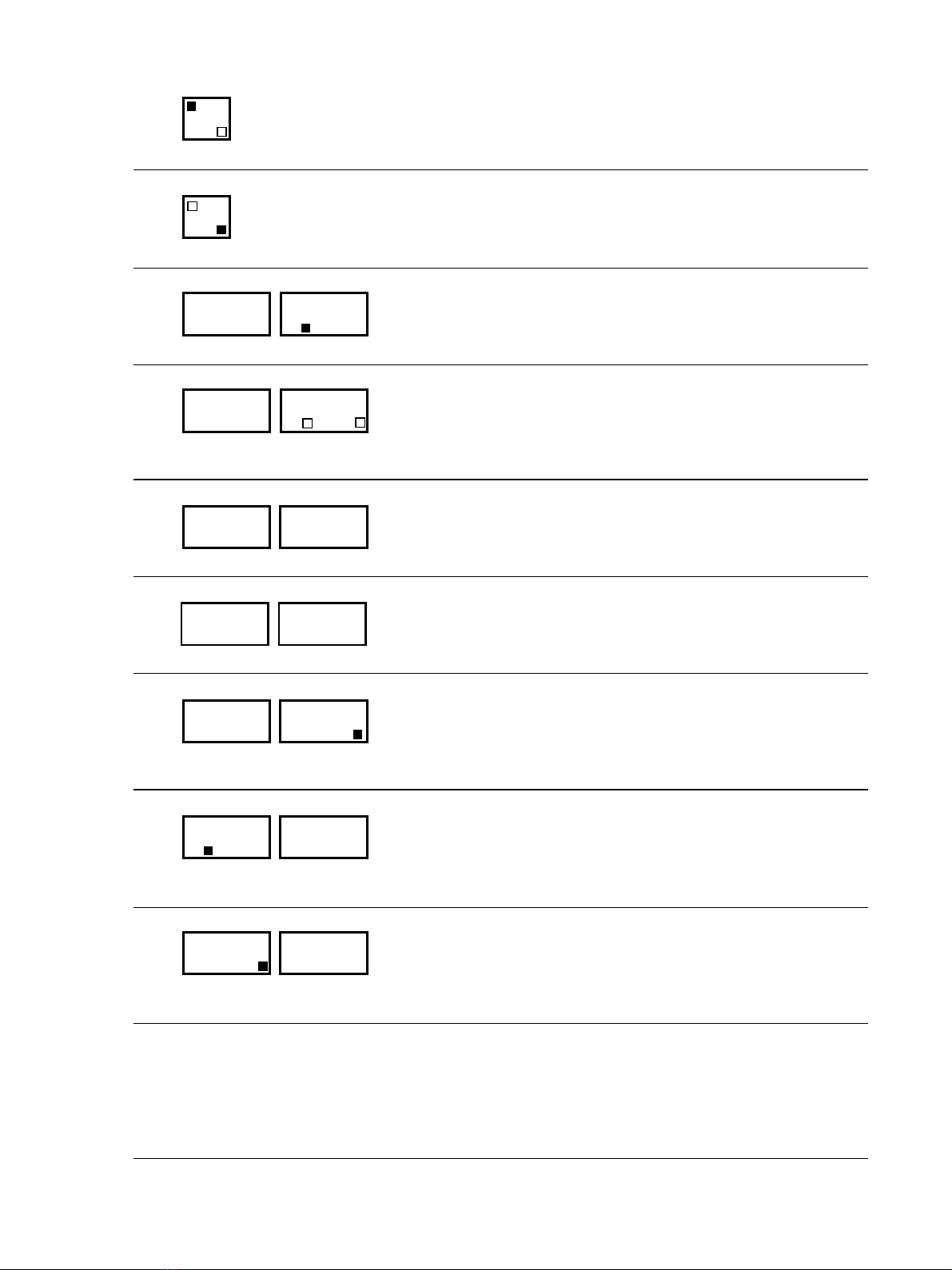

“Motor Reset” key with lamp (10). The lamp lights up when there is a malfunction in the pump circuit

(malfunction see Section 6.2, Display 19 or 20).

“Over Temp” Lamp (11) lights if:

– the safety thermostat fitted in the unit has tripped (fluid temperature), see also Section 11.1, Fig. 2.

– the programmed max. limit value “S¯¯” from probe Sn1 or Sn2 is exceeded (Display S¯ ¯, see Sec-

tion 11.1, Fig. 2).

“Low Level” Display (9) lights up or flashes when the level of the heat transfer fluid in the unit is

insufficient (see also Section 6.2, Display 23).

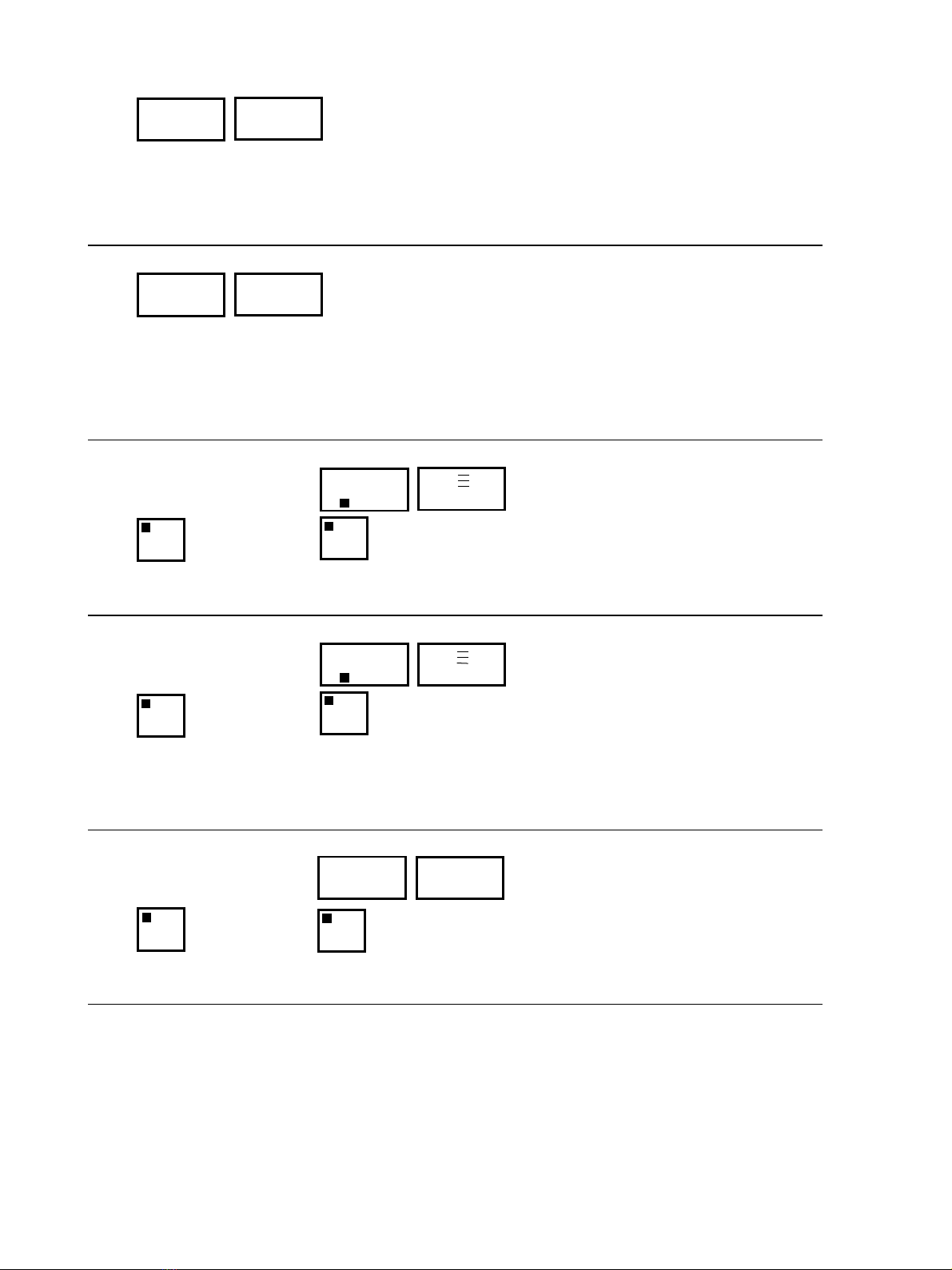

“Flow” key with lamp (8)

When the key is pressed, the amount of flow in l/min or GPM(US) appears in the display to the right,

when flow measurement is present. Exception: in leakstop and drainage modes the display “---” ap-

pears.

Lighting of the lamp: see Section 6.2, Display 24 or 25.

Blocking of the set value. The set value “SP1” can be blocked as follows: press the “P” key twice

and then the “Alarm Reset” key once within 5 seconds. Deblocking occurs the same way.

4. Switching on

Once the main switch on the unit is switched on, a functional test will run for approx. 3 seconds. Dur-

ing the test, 6 dots will appear in the two display fields (Section 6.1, display 1).

If another display lights up, see Section 6.1.

After the test has been run successfully, the dots will disappear; the RT 45 is ready for operation. In

the right display field, “oFF” will appear.