Replacement of Poppet Assembly and Seat/

Seal Assembly

If the Nozzle is leaking only while connected to the receptacle you

may replace the Seat/Seal Assembly (p/n 14255) without replacing

the Poppet assembly (p/n 13960). The current poppet assembly

can be used with the new Seat/Seal Assembly if the nozzle does

not leak when disconnected. If the nozzle experiences any leakage

while disconnected, both the Poppet and Seat/Seal Assemblies

need to be replaced.

Parts Needed

(Parts sold separately)

Poppet Assembly

p/n 13960

Receptacle Interface Seal

p/n 14591

Seat Assembly

p/n 14255

(Contains Receptacle Interface Seal) Socket Tool

p/n T-2961

NOTICE

If purchased separately, the receptacle interface seal must

be assembled with the brass retainer according to Macro

Technologies instructions using the proper seal repair tool

kit: p/n 14590.

Tools Needed: In addition to the above parts, you will also need

an open ended 1-18” wrench a Torque Wrench (recommended) or

Socket Wrench with a 1” socket attachment and a vise.

Open end side of seal

facing retainer flange

Closed end side of seal

facing retainer threads

NOTICE

Make sure that the removal tool is all the way pushed into

the mating Seat/Seal Assembly hex or you could possibly

strip the retainer. Use care when removing the retainer.

If not removed carefully, the poppet may pop out of the

Nozzle, potentially causing personal injury and damage

the parts.

1. Remove all items from their shipment packaging taking care in

handling them so that they are not damaged. Carefully inspect

parts to ensure that all sealing surfaces are clean, free of dirt

and contamination.

2. Place the wrench in the vise and secure the end of the Nozzle

as shown to the left.

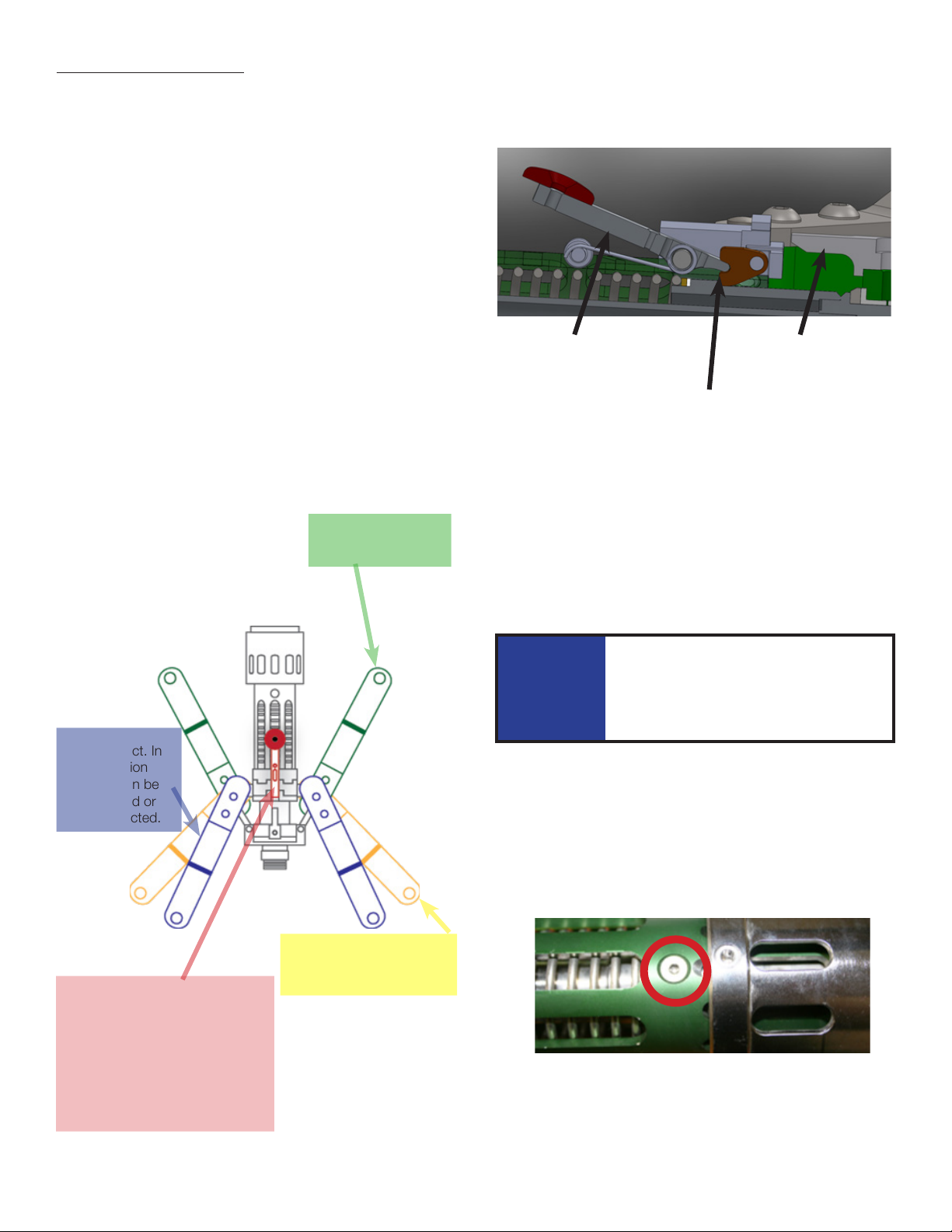

3. Align Socket tool (T-2961) with Seat/Seal Assembly hex

and place 1” socket wrench onto Socket tool and turn

counterclockwise to remove the Seat/Seal Assembly. Once

the Seat/Seal Assembly is fully unscrewed, the spring behind

the poppet Assembly will push the Poppet Assembly out of the

Nozzle.

4. Remove the old Poppet Assembly and Seat/Seal retainer. If

the Nozzle is only leaking while connected, the current poppet

Assembly does not need to be replaced. However, it should

still be carefully inspected to ensure that all sealing surfaces

are clean and undamaged.

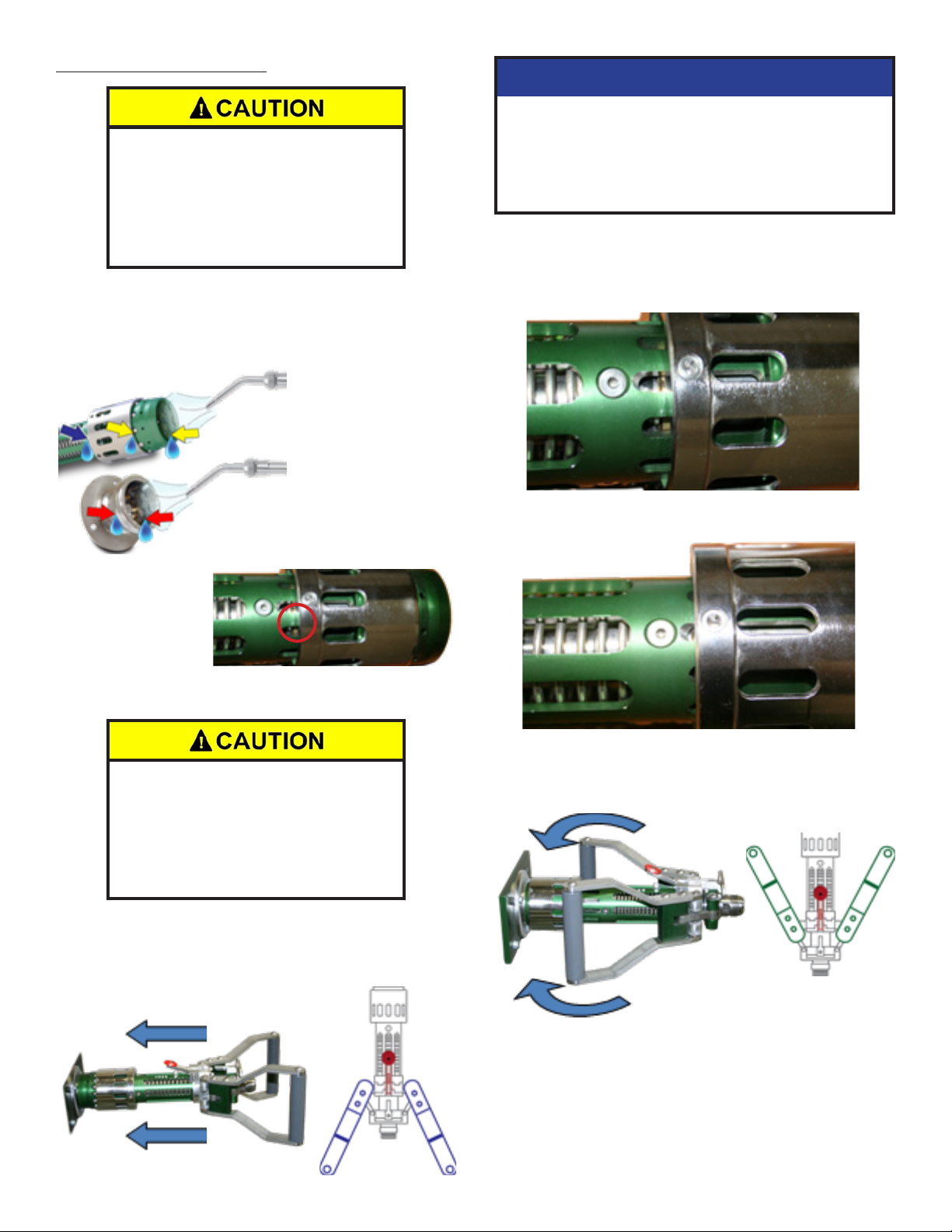

Inspect Seat/Seal Assembly (p/n 14255) to confirm that

receptacle interface seal has been positioned correctly. The

seal should be positioned with the open side facing the retainer

flange. The closed side should be facing towards the retainer

threads.

If purchased separately, the Receptacle Interface Seal must be

assembled with the brass retainer according to Macro Technologies

instructions using the proper seal repair tool kit: p/n 14590. See

replacement of Interface seal if you are repairing the Receptacle

Interface Seal separately.

5. Use the Socket Tool (p/n T-2961) to carefully align Poppet

Assembly and Seat/Seal Assembly.

6. Place the Poppet assembly, Seat/Seal Assembly, and Socket

Tool on the spring with the tool facing away from the nozzle.

Use of Socket tool T-2961 is important and critical in

order to properly guide all components into place. Failure

to properly guide components into place with Socket

Tool T2961 may result in misalignment on critical sealing

surfaces.

If not aligned correctly, the seal on the poppet Assembly

and/or the seal of the Seat/Seal Assembly may become

damaged.

NOTICE

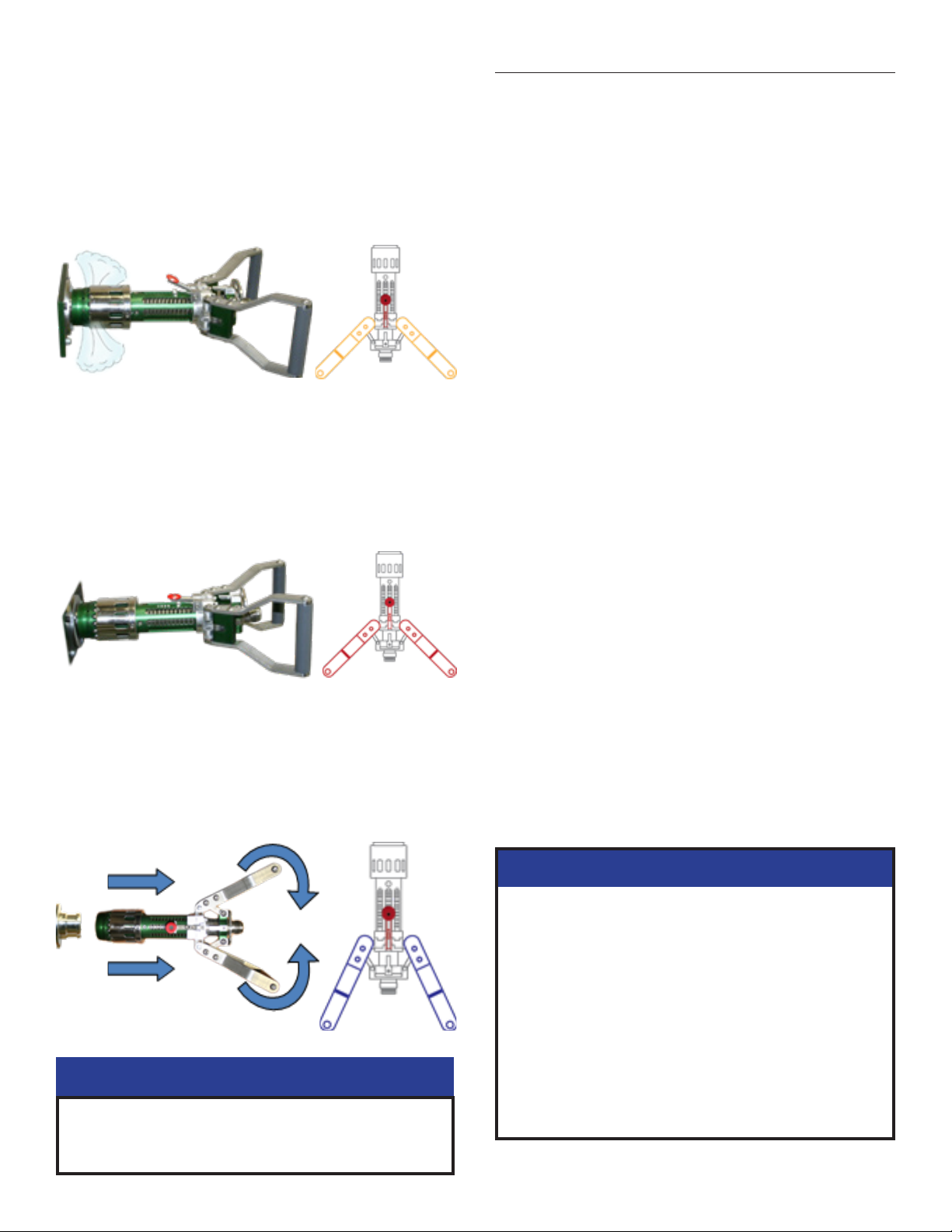

7. Push the Poppet assembly down by hand while threading the

Seat/Seal Assembly clockwise onto the Nozzle. Once you feel

the assembly threading into the Nozzle, you can remove the

pressure.

If assembled backwards, the seal will fail

prematurely.

7