1. Introduction

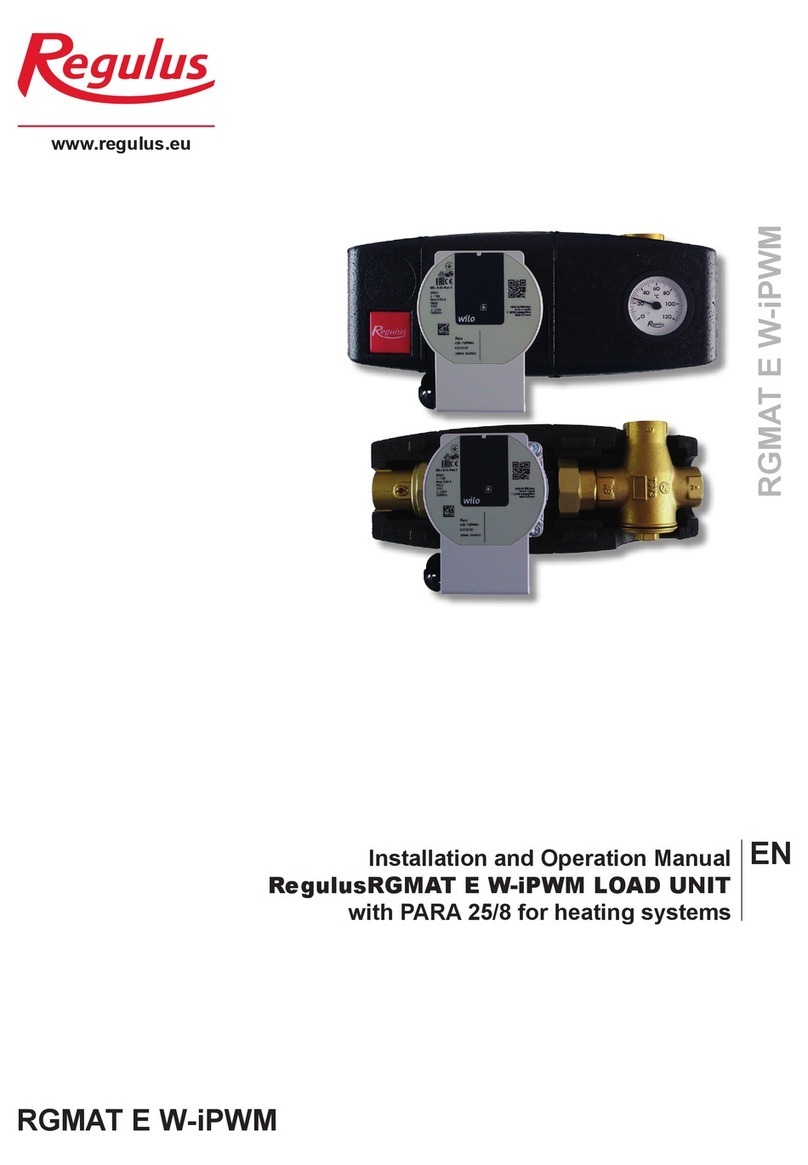

RegulusRGMAT E G60 Load Unit makes boiler installation quicker as it contains all important

components needed for boiler circuit circulation and boiler protection against low-temperature corrosion.

It is designed to be installed directly on a boiler return piping. The min. distance of the pipe axis from a

wall is 100 mm to enable insulation removal if needed.

This Load Unit is intended for hydronic fireplaces and solid-fuel boilers.

2. RGMAT E G60 Description

RGMAT E G60 keeps the temperature at the boiler inlet above the flue gas condensation temperatures,

which prevents so called low-temperature corrosion of the boiler combustion chamber. This limits con-

densation and boiler tarring significantly, the efficiency of fuel combustion increases and service life of

the boiler is extended.

Main Features

Function maintaining a minimum inlet temperature into a boiler (fireplace) through a load

valve

Application Load Unit for solid-fuel boilers and fireplaces; it prevents low-temperature

corrosion and boiler (fire) fouling

Description consists of a UPM3 FLEX AS pump, ball valves with union nuts, TSV3B valve

(with automatic bypass balancing), thermometer, insulation

Working fluid water; water/glycol mixture (max. 1:1) or water/glycerine mix-ture (max. 2:1)

Installation on boiler return piping, min. distance of the pipe axis from a wall is 100 mm

RGMAT E G60 Technical Data

Fluid working temperature 5 - 95 °C

Max. working pressure 6 bar

Min. working pressure 0.5 bar

Max. ambient temperature 5 - 40 °C

Max. relative humidity 80 %, non condensing

Load valve control range tvalve,opening +5 °C

Valve Kvs (A→AB direction) 6.2 m3/h

Valve Kvs (B→AB direction) 4.4 m3/h

Power supply 230 V, 50 Hz

Insulation material EPP RG 60 g/l

Overall dimensions 325 x 140 x 220 mm

Total weight 3.25 kg

Connections 3x G 1" F

Accessories

Bypass with float non-return valve code 16126

Codes max. boiler output

19083 for opening temperature 45 °C max. 46 kW

19090 for opening temperature 50 °C max. 42 kW

19086 for opening temperature 55 °C max. 36 kW

19092 for opening temperature 60 °C max. 32 kW

19089 for opening temperature 65 °C max. 26 kW

19091 for opening temperature 70 °C max. 22 kW