3

Collector description

REGULUS Flat Solar Collectors are designed for solar

domestic hot water heating (DHW), backup- and pool

heating with solar energy. Solar radiation penetrates the

glass and is intercepted by an efcient absorption layer

applied on an all aluminum absorber. The heat is then

transferred into heat transfer uid. The absorber is sea-

led in a compact frame with high quality thermal insulati-

on. The collectors are designed for year round operation,

that’s why they work in a separate primary circuit lled

with antifreeze heat carrier.

The collectors are not intended for direct wa-

ter heating. If different heat transfer uid is used

than specied by the manufacturer, irreversible

damage to the collector may be done.

Transport, handling and storing

Collectors shall be transported in their original packing,

in upright position (standing on their shorter side) or lying

horizontal with glass upwards, stack of max. 14 pieces

on a pallet.

During handling the collector glass shall be always

facing upwards.

Please check the condition of the collector upon recepti-

on from your supplier or forwarder. Later claimed mecha-

nical damage (frame, glass, connection) will be refused.

When stored, the collector shall not be exposed to rain

and its absorber exposed to solar radiation.

Scope of supply

1. KPG1H-ALC collector

2. Instruction manual

3. Warrant Certicate

General instructions for installation

The installation must be done by a trained worker or a

specialized company.

During installation and before commissioning, it is

necessary to cover collectors in order to avoid overhea-

ting and possible burn injury to the installer.

Prior to installation, conditions set by the roong manu-

facturer and the max. permissible roof load shall be

checked.

Mounting method for solar collectors shall always re-

spect local conditions, i.e. roof inclination and weather

inuence on the overall load on the collector. Kindly con-

sult the fastening method with a structural statics expert.

During installation the collectors and accessories shall

be handled carefully. Defects caused by improper hand-

ling or DIY installation are not cover by warranty.

Generally valid rules and standards for occupational

safety shall be respected during installation. This con-

cerns mainly technicians walking on a roof and the secu-

ring the area against objects falling down from a roof.

Only REGULUS mount elements may be used. Other

fastening elements may be used only with a written

approval from REGULUS company.

Collectors shall not be exposed to solar radiation un-

til commissioned. The absorption surface may get

damaged.

Collectors shall be installed and operated in compliance

with this Manual and with respective generally valid rules

and norms.

Collector placing

The collector must be placed outdoors. The glass

absorption surface should be orientated to South, with

deviations not over 45° (Southwest or Southeast). For a

year round operation the right inclination angle is 40°-

50°, for summer operation smaller inclination is better

(30°).

Collectors are installed according to marking.

The collectors shall be installed at an angle

between 15° and 75°.

On inclined roofs it is recommended to install

solar collectors as close to the roof ridge as possible.

Should this solution be impossible, then protections

against snow slide shall be installed above the collec-

tors.

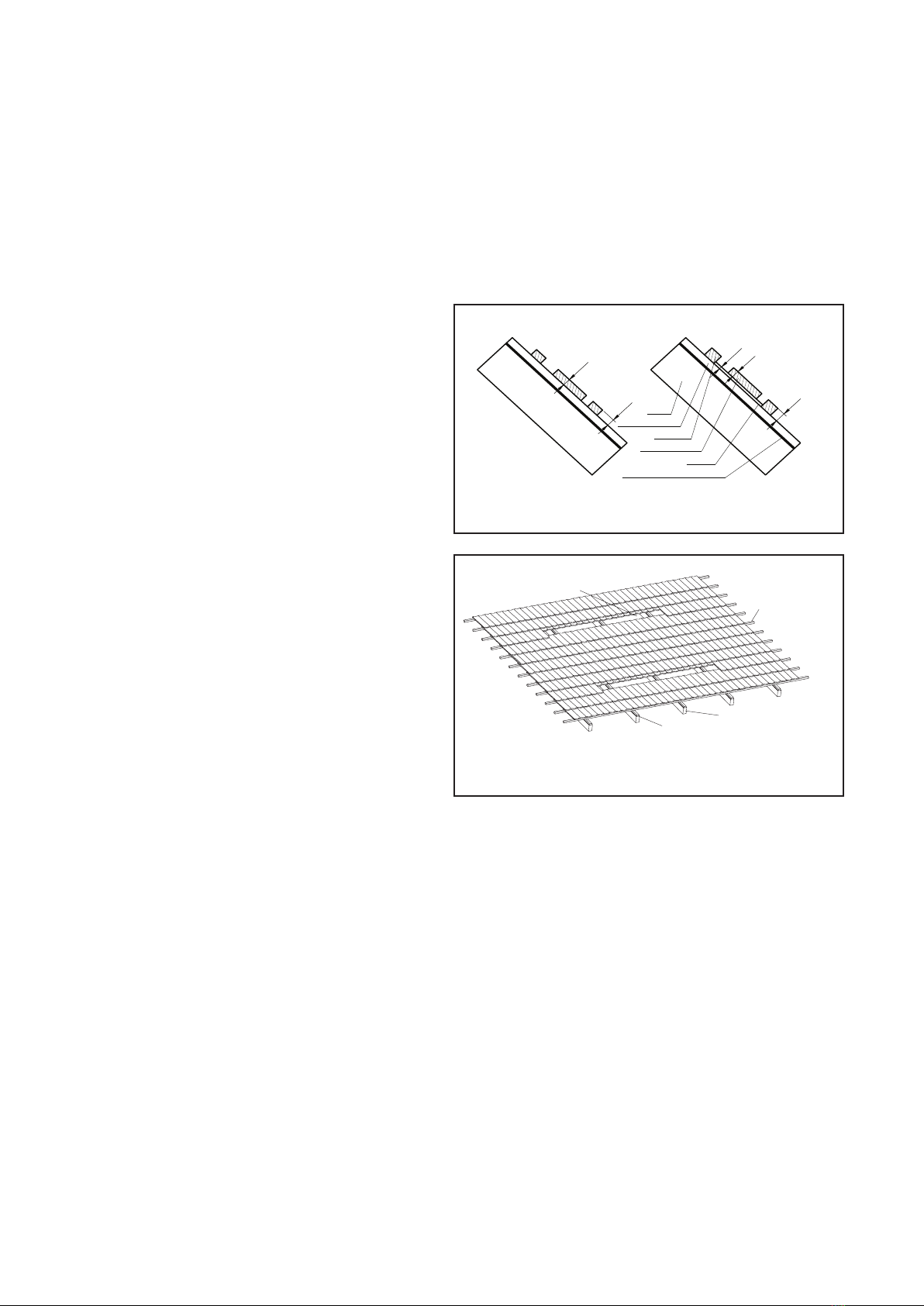

The numbers of roof anchors shown in the Mount Kits

for Fitting and Connecting Regulus Solar Collectors are

designed for the following load:

Max. permissible snow and wind load ≤ 1,8 kN/m2

Max. permissible wind load - negative pressure ≤ 1,0 kN/m2

The customer/user shall be informed about this fact

prior to starting installation of a solar thermal system. If

a higher load than shown above is expected in the area

in question, a statics expert shall be consulted and more

roof anchors designed, or other measures taken that

would ensure safe collector tting. Regulus refuses any

responsibility for damage caused by wrong design of

collector fastening.

GENERAL INSTALLATION AND OPERATION INSTRUCTIONS