│6

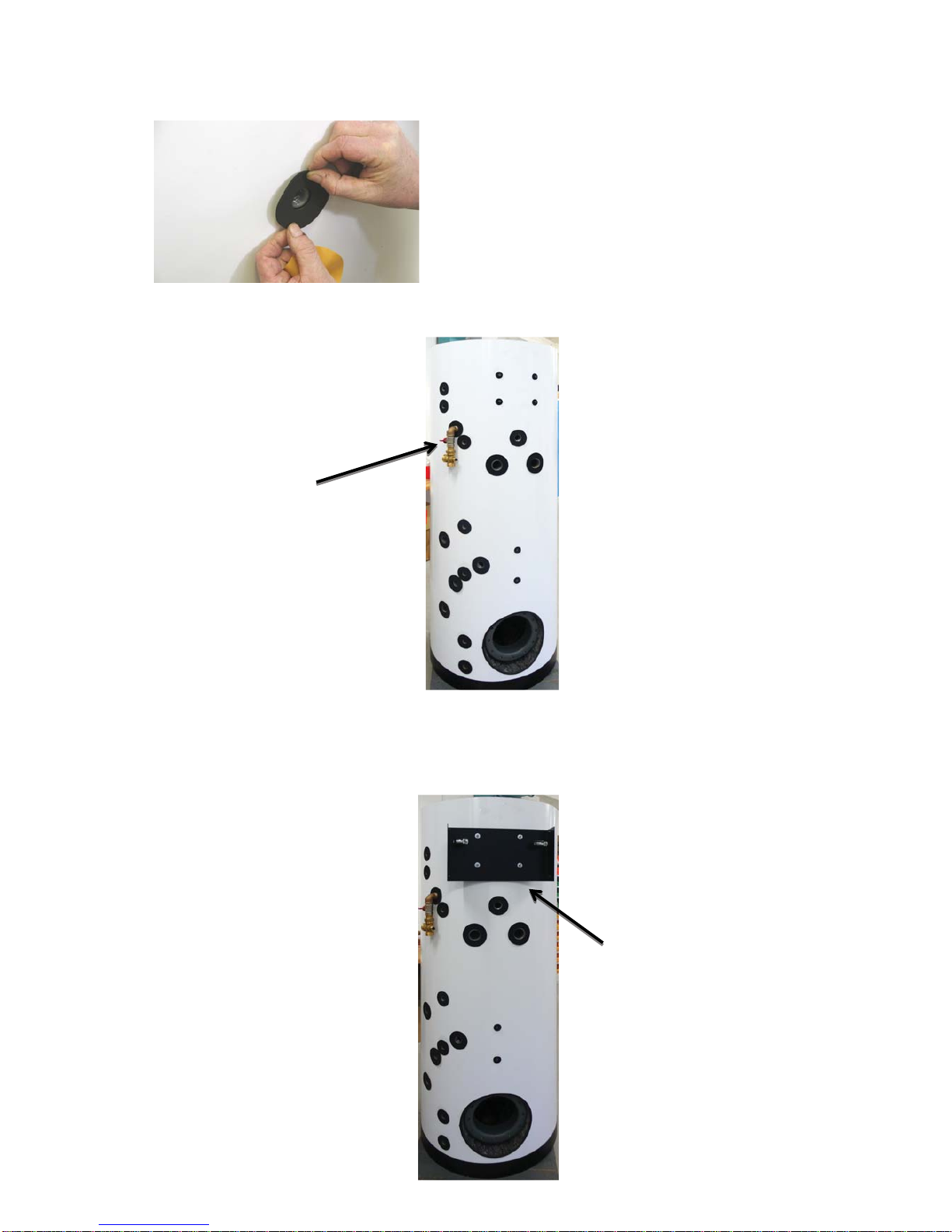

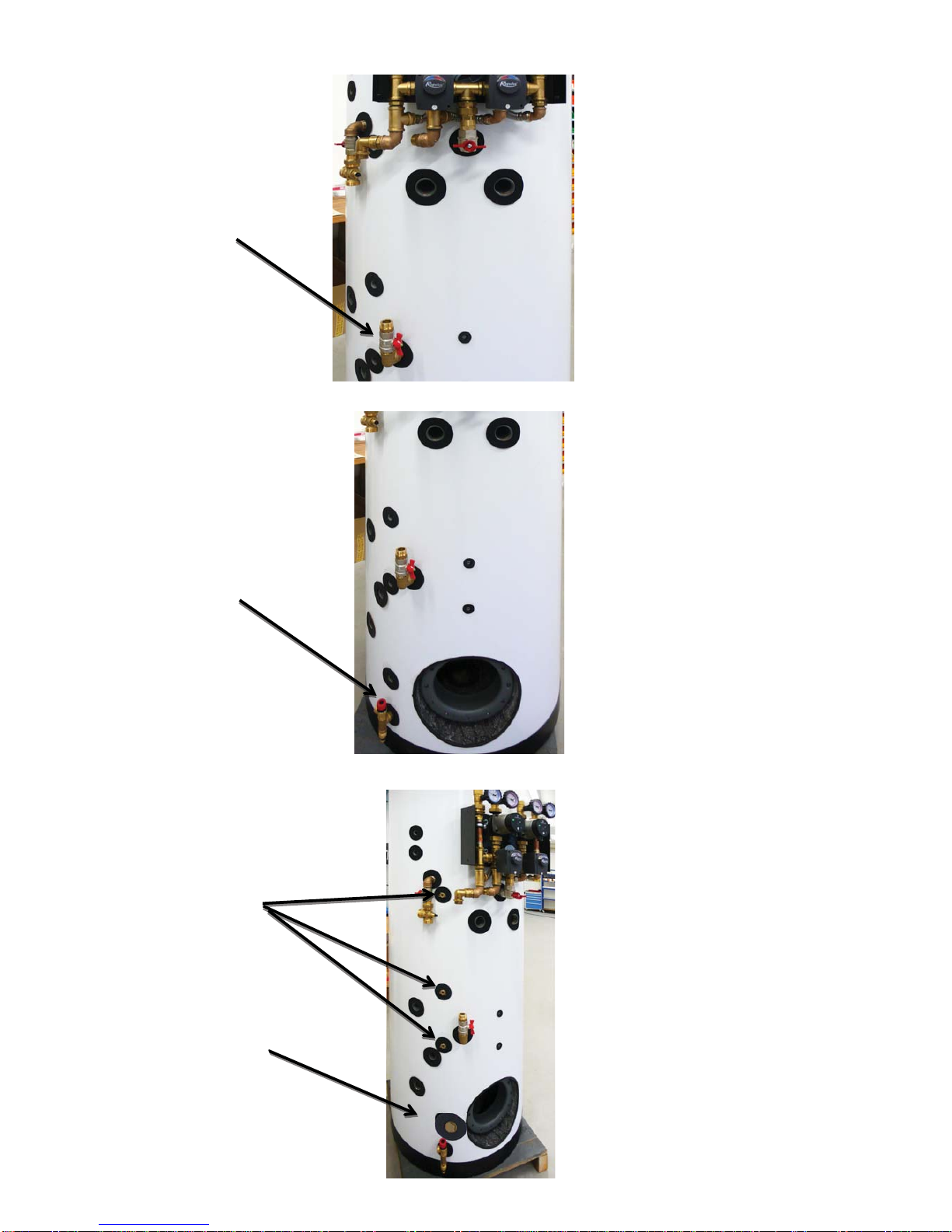

5.1 Mounting pump stations and accessories onto VEGA 390

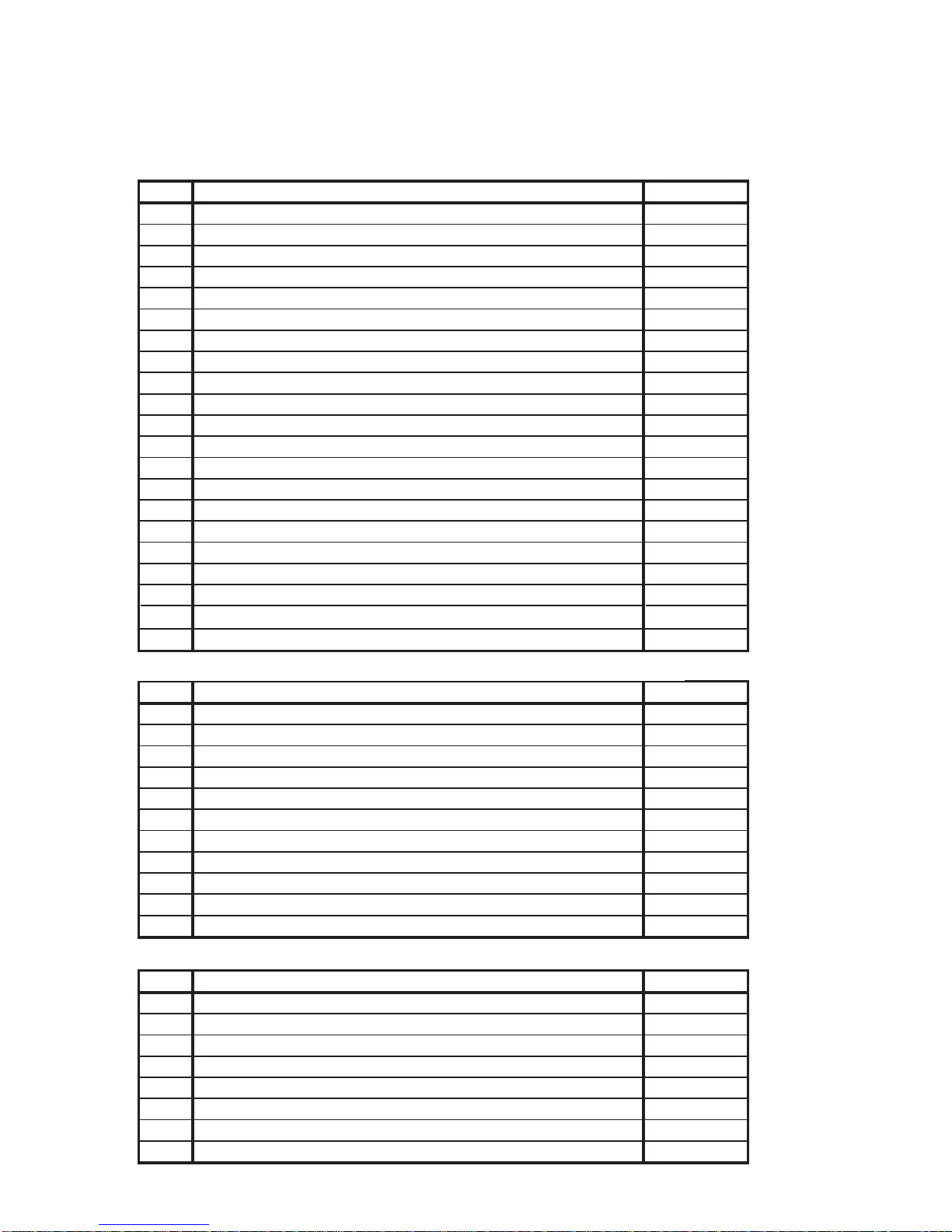

SCOPE OF SUPPLY:

Vega 390 Thermal Store, code 12968 (the other one, code 12967, differs only in the number

of heating circuits):

Code Name Qty

12104 HSK 390 V Thermal Store, no insul., 1 stainless steel DHW coil 1 pcs

12036 Insulation for HSK390 V Thermal Store - NEODUL - code 12104 1 pcs

12224 Pump Station for Thermal Store - 2 circuits 1 pcs

12690 Angled Ball Valve Assy for LYRA 1 pcs

13494 1” Elbow Assy out to HP, for VEGA 390 1 pcs

13476 Zone Valve Assy in from HP, for VEGA 390 1 pcs

13477 Zone Valve Assy out to HP, for VEGA 390 1 pcs

13478 1” Elbow Assy in from HP, for VEGA 390 1 pcs

13479 1” Elbow Assy in from h. circuit, for VEGA 390 1 pcs

13497 1” Valve Assy out to h. circuit, for VEGA 390 1 pcs

13529 Safety & Drain Valve Assy for VEGA 390 1 pcs

13237 Accessory Kit for LYRA and VEGA 1 pcs

6230 Flange for PS2F tank, d=312, no holes 1 pcs

13485 Kit for connection of assys onto VEGA 390 1 pcs

154 Sheath 7x8-100, 1 sensor, 1/2" 3 pcs

10845 Capillary spring, small, 1/2", stainless steel 3 pcs

12714 Cover for 2-circuit pump station, for 380l Thermal Store 1 pcs

12223 Front insulation for cover for 2-circuit pump station 1 pcs

12721 Top insulation for 2-circuit pump station, 380l 1 pcs

12713 Black knurled screw, M6x1-10 PA 6.6 4 pcs

Code Name Qty

6969 1" hex nipple, MM, thick wall 1 pcs

13481 DN 20 pipe (1" nut) l=1010 mm 1 pcs

13489 DN 20 pipe (1" nut) l=690 mm 1 pcs

13488 DN 25 pipe (5/4" nut) l=490 mm 1 pcs

13484 DN 25 pipe (5/4" nut) l=125 mm 1 pcs

7187 Insulation DNa 35, 13 mm thick (2 m) 1 m

6447 Insulation DNa 28, 13 mm thick (2 m) 2 m

12996 M6x16 stainless steel bolt (hex socket) DIN 912/A2 4 pcs

7853 6.5 washer (large diameter 3d) 8 pcs

9980 1" nut gasket - 18,5x30x2 PTFE 4 pcs

9981 5/4" nut gasket - 25x39x2 PTFE 4 pcs

Code Name Qty

11969 6/4" FF ball valve 1 pcs

7627 6/4“ Hex nipple, MM, thick wall 2 pcs

8757 6/4" T-piece in brass, FFF 1 pcs

8766 Reducing hex nipple 1"x6/4" MM 1 pcs

7049 1" T-piece in brass, FFF 1 pcs

6969 1" Hex nipple, MM, thick wall 1 pcs

7701 Reducing hex nipple, 1“x1/2“, MM, brass 1 pcs

11713 1/2“ drain valve, no handle, with cap 1 pcs

9097 Plug 1/2“ + gasket, brass 1 pcs

12968 - VEGA 390 2 circ.

13485 - Assemblies Connection Kit for VEGA 390

13437 - Expansion Vessel Connection Kit