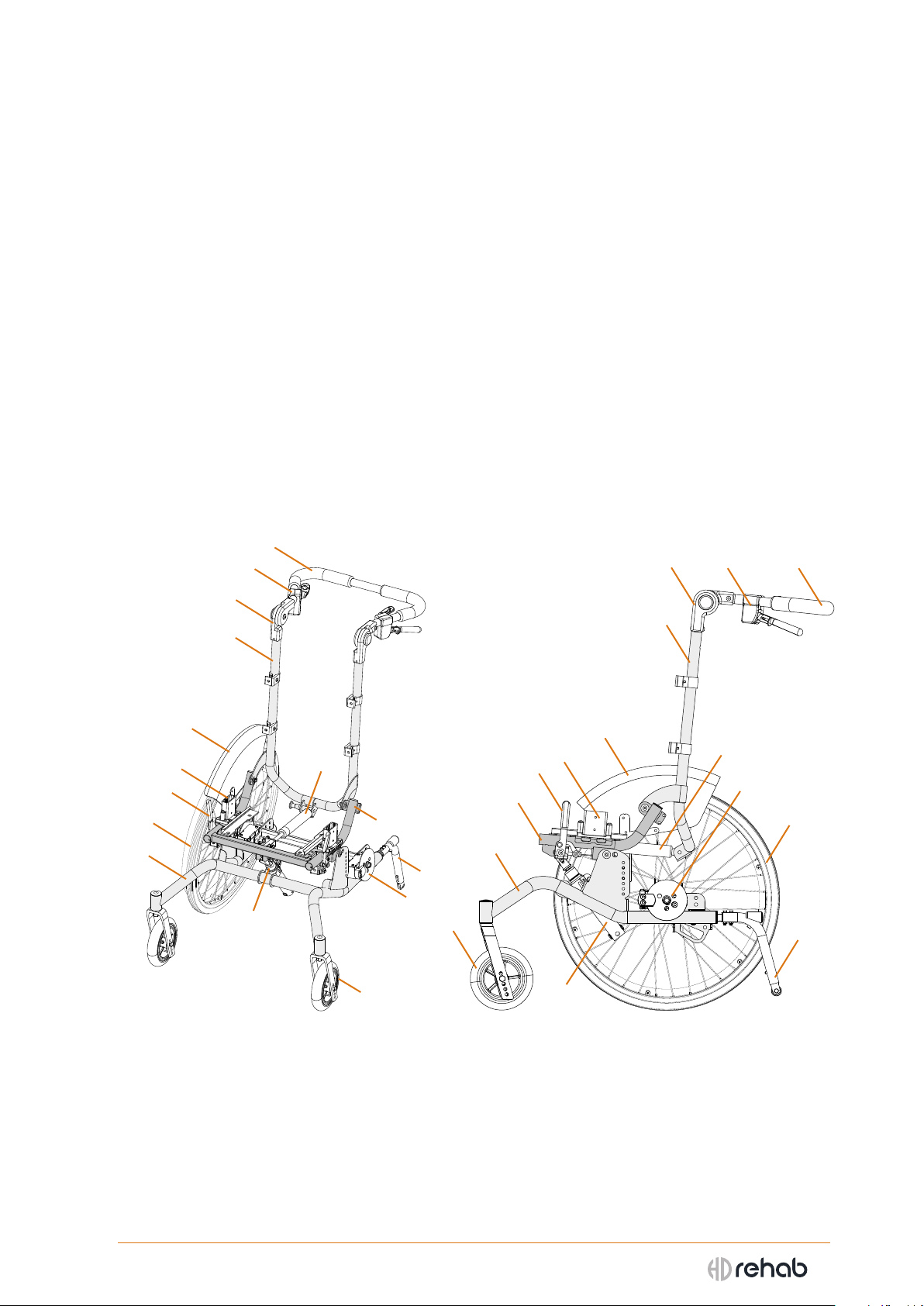

4HD Motion | Technical Information

1. GENERAL INFORMATION

The product is a comfort wheelchair that comes in two versions, HD Motion 22 and HD Motion 16.

HD Motion 22 is intended for children/youth or small adults who can to some degree drive the

wheelchair independently. It can also be used if the user is unable to drive independently. HD Motion

16 is only for users who cannot drive independently.

HD Motion is intended for users in need of excellent comfort and support when seated. The seat and

back can tilt in various positions to give the user a variety of seating options for activity and rest.

Prescription by a medical professional is required before beginning to use HD Motion. This applies to

new wheelchairs as well as when a used chair changes users. All prescription and adaptation of the

wheelchair must be carried out by qualied personnel.

If the user has movement patterns or behaviour that strains the wheelchair excessively a reinforced

model may be needed. This applies for example to users with increased tonus or spasticity.

The wheelchair is approved for use as a seat during transportation in vehicles.

HD Motion is a Class 1 Medical Device, CE-marked per EU 217/745 (MDR).

1.1 Important documents

It is useful to have the following documents at hand when working with HD Motion:

95431-1 Information about custom-made products

Information regarding regulations that apply for adaptations and modications of

medical products.

96711-1 Risk Information - Special congurations and Accessories

Information about increased risks when using certain special congurations and

accessories.

96764-1 Labelling

Information about which labels are to be found on the wheelchair.

96730-1 Maintenance Schedule

Instructions for maintenance to maximise the life and performance of the wheelchair.

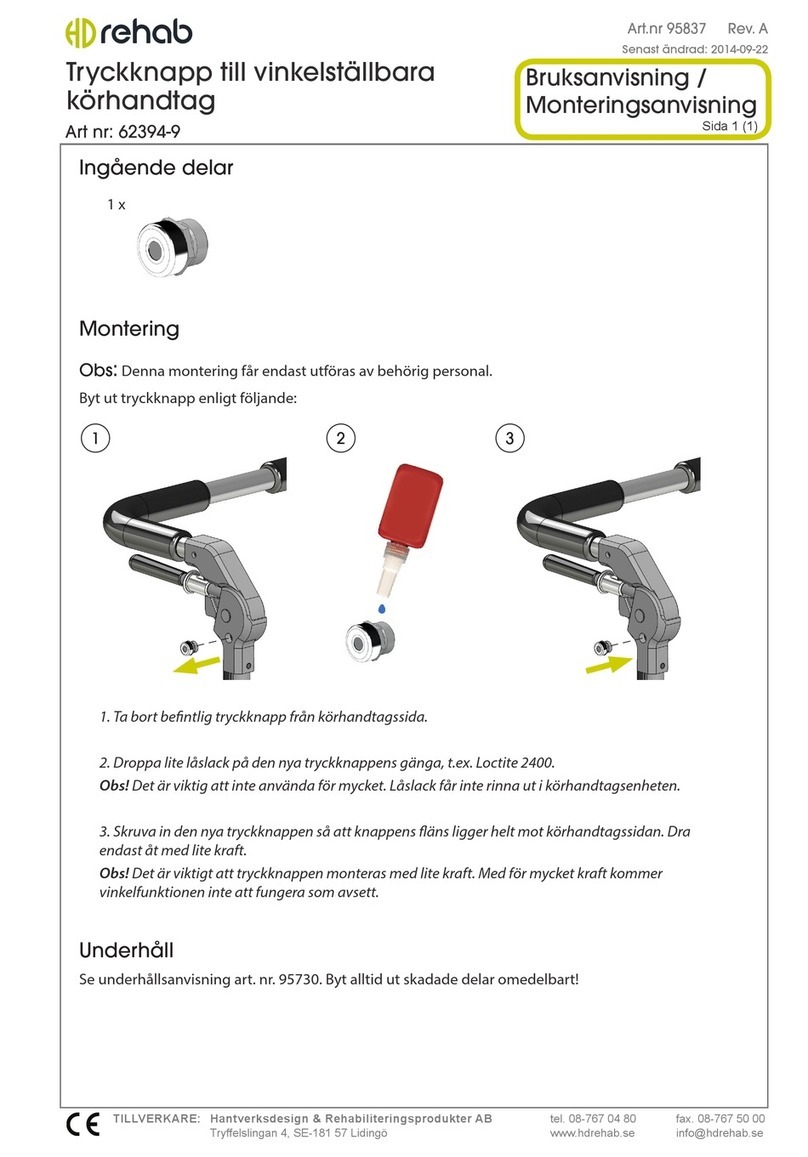

1.2 Lubricants and thread lockers

Table 1 details recommended lubricants and threadl ockers.

Table 1 - Recommended lubricants and thread lockers

Area of use Lubricant type Product used by HD Rehab

General lubrication of sliding surfaces etc. Synthetic food grade grease Fuchs Cassida EPS 2

Vendor: Ikaros AB

Locking of screws, permanent, e.g. wheel

axle pin

High strength thread locker Loctite 2700

Locking of screws to crossbars etc. that

may be removed for repairs

Medium strength thread locker Loctite 2400