5

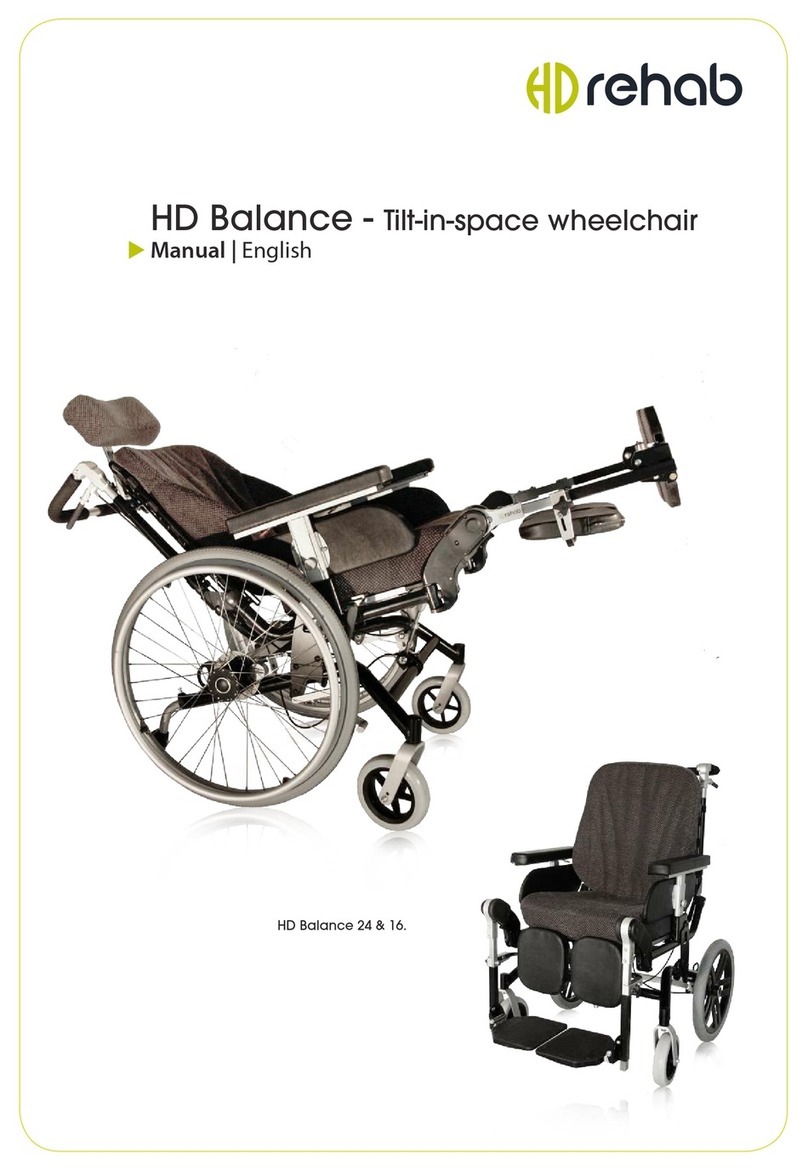

HD BALANCE | Technical Information

2. Chassis Construction

The HD Balance chassis is constructed of three interacting frames; wheel frame, seat frame, and

back frame. These are attached to each other at a number of points such that desired geometry

for balance, recline, and seat tilt can be achieved. The wheel frame and seat frame are connected

by balance plates. The balance plates are critical to the characteristics of the wheelchair.

The two models, 16 and 24, have identical chassis with the exception of the wheel frame, where

the plates for wheel attachment have different designs.

2.1 Chassis conguration options

The HD Balance chassis can be modied to change the wheelchair characteristics. The standard

conguration is the reference point for any given data in terms of characteristics, function,

measurements, and tests against existing standards. Changes to the chassis conguration come

with both positive and negative consequences. Therefore the standard conguration should be

used wherever possible.

The following modications can be made:

- Change of balancing plates. Provides raised seat height, lowered seat height, or moving

the balance point forward or backward. Described in section 2.4.

- Lengthened seat frame. Provides increased seat depth. Must be selected with initial

wheelchair order, cannot be changed after assembly.

- Increased / Limited tilt. Described in section 2.5.

- Change of tilt rod. Eects tilt range per document 95758-1. Described in section 2.6.

- Change to rod in place of gas spring. Provides a xed back angle between 90 and105

degrees. Described in section 2.7.

- Moving wheel mounting point 50 mm backward. Makes the wheelchair more stable but

with somewhat poorer handling. Described in section 2.9.

2.2 Change of back frame

1. Remove the push handle by pulling it competely out of the back

frame. Be careful with the cables!

2. Remove the back cushion and disassemble back system (Flexi-

back or Fixed back).

3. Release the rear bracket of the gas spring by pulling out the pin

so that the gas spring can be gently removed.

4. Remove the retaining rings on the inside of the back system

attachment points (A, g1). Tap the pins so that the back frame

can be lifted o. NOTE! It is not necessary to remove the pins

completely in order to release the back frame.

5. Remove the back frame and replace it with the new frame.

6. Assemble the new frame by repeating the same steps in reverse

order. Be careful not to damage the retaining rings, replace

them with new rings if necessary!

2.3 Change of seat frame

1. Remove the back frame per section 2.2 steps 1-4.

2. Remove seat cushion, seat board, leg rests and armrests.

3. Remove tilt rod and gas spring per section 2.6 steps 1-5.

4. Remove the screws from both balance plates (A, g 2).

5. Carefully press one balance plate outwards (B) so that

the seat frame can be lifted o. Be careful when the seat

frame comes free as there can be a pinching hazard and

cables can be damaged.

A

Fig 1

B

A