THERMOJET®H-2500E SERIES

OIL PURIFIER SYSTEM

INSTALLATION AND OPERATING MANUAL

Doc # 77740119

Rev 15

Date June 2020

Page

of

Table of Contents

I GENERAL INFORMATION.........................................................................................................................5

Manufacturer Contact Information ..............................................................................................................6

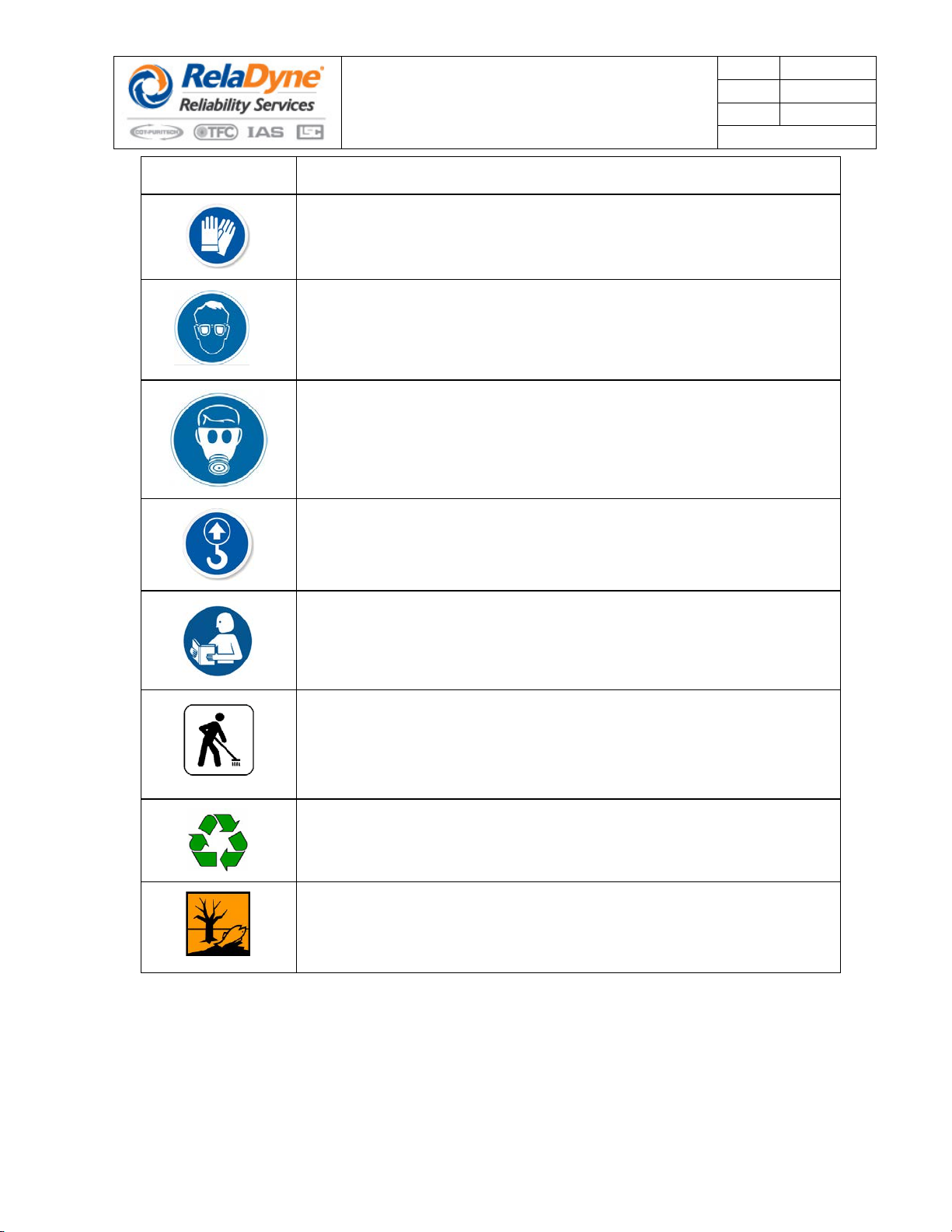

Explanation Of Graphic Symbols In The Documentation ...........................................................................7

II UNIT IDENTIFICATION AND LABELING .................................................................................................10

ThermoJet ® Model H2500- Model Code Designations...........................................................................11

Model Code Designation Key ...................................................................................................................12

Tag Detail for H2500E Model Oil Purifiers................................................................................................13

III DESCRIPTION OF THE PRODUCT........................................................................................................14

Principal of Operation................................................................................................................................15

Dewatering................................................................................................................................................15

Flow through the Unit................................................................................................................................15

The Jet Mixer............................................................................................................................................15

Return of Clean Oil....................................................................................................................................15

MountingOptions ......................................................................................................................................15

IV INSTALLATION........................................................................................................................................16

Receipt Inspection ....................................................................................................................................17

Placement of Equipment...........................................................................................................................17

Inlet and Return Oil Piping Connections...................................................................................................18

Condensate Purifier Connection...............................................................................................................20

System Exhaust Connections...................................................................................................................21

Electrical Power Connection.....................................................................................................................22

Grounding .................................................................................................................................................25

V SYSTEM START-UP AND OPERATION .................................................................................................26

Start-Up Procedures .................................................................................................................................27

Heater Operation:......................................................................................................................................32

Adjusting System Pressure.......................................................................................................................35

System Discharge Pressure .....................................................................................................................36

System Vent Operation.............................................................................................................................37

Monitoring Normal Operation....................................................................................................................39

Dailey ThermoJet Oil Purifier System Operational Checks......................................................................41

System Shutdown.....................................................................................................................................42

VI ROUTINE MAINTENANCE......................................................................................................................43

Maintenance Checks ................................................................................................................................44

General Inspection....................................................................................................................................46

Oil Filter Maintenance...............................................................................................................................47

Y-Strainer Maintenance ............................................................................................................................48

Condensate Purifier Assembly Maintenance............................................................................................49

Oil Mist Eliminator Maintenance ...............................................................................................................50

Air Breather Maintenance.........................................................................................................................51

Separation Vessel Maintenance...............................................................................................................52

Oil Heater Maintenance............................................................................................................................55

Auto Tune Oil Heater Controller................................................................................................................60

Check and Adjust Operating Pressures....................................................................................................62

Verify Low Oil Pressure Switch Operation................................................................................................63

Verify Oil Heater High Temperature Cutout Operation.............................................................................65