Page 9 of 13

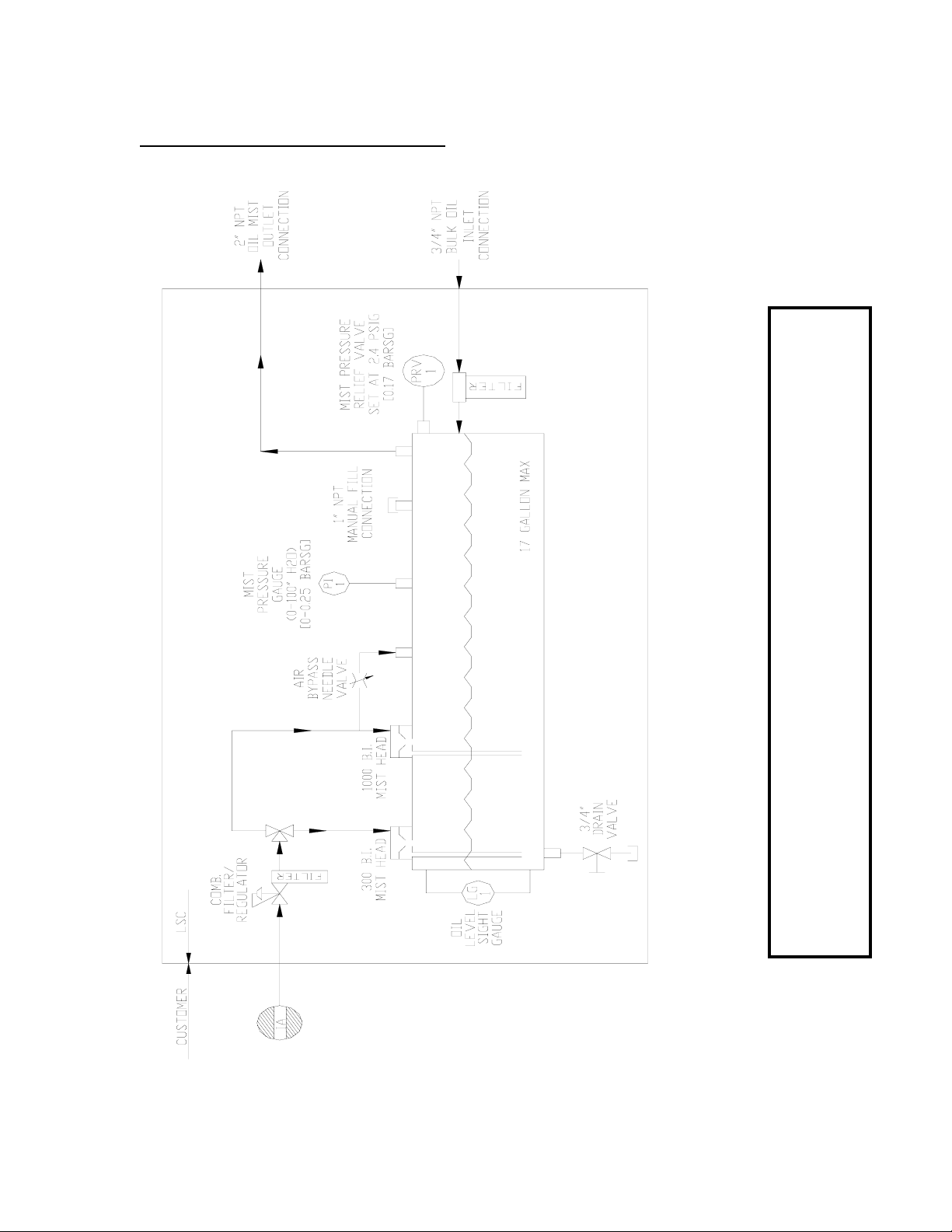

LUBRIMISTKMODEL “PRY330”

PART #77740220

REV 2

April 2007

Operation

The daily operation of the “PRY330” oil mist system consists of checking the oil mist

generator and the lubricated equipment. As machinery is added and removed from the

equipment preservation yard, the air pressure regulator will need to be adjusted to

maintain the proper mist pressure. Oil consumption will also vary with the quantity of

equipment items. Except for emergencies, routine adjustment of the generator is not

required while the equipment population is stable. The “PRY330” oil mist preservation

system, once installed and balanced, supplies a constant amount of oil mist to a number

of lubrication points.

Variations in the oil mist pressure or regulated air pressure (supply pressure) from the

initial set points is an indication that some component of the mist system or compressed

air supply system may have malfunctioned. Adjustments of the controls to offset the

failure symptom may lead to more serious problems before correction of the root cause

can be made. Please refer to the trouble shooting section of this manual for suggested

corrective actions.

The following checks should be made on a daily basis:

1. Check reservoir oil level, see start-up procedures on how to fill the oil reservoir.

2. Check the regulated air pressure and mist header pressure. Changes or fluctuations in

mist pressure readings indicate broken or plugged lines or reclassifier fittings in the

distribution system. These problems must be corrected before adjusting the regulated

air supply.

Maintenance

The following maintenance procedures should be performed on at least a semi-annual

basis to help ensure proper system operation. If your “PRY330” unit is installed in an

extremely dusty or humid environment or if you are concerned about the quality of your

compressed air supply, the maintenance schedule should be accelerated. Consult with the

nearest LSC office/service center for further discussion and recommendations.

3. Replace air filter element (P/N 77-500-472) and oil filter element (P/N 77-500-487).

4. Inspect and clean interior of the “PRY330” reservoir.

Use lint-free rags to wipe the reservoir.

5. Inspect and clean the oil suction screen.

Use cleaner that is compatible with the oil and use lint-free rags.

IMPORTANT: DO NOT DISASSEMBLE THE VORTEX MIST HEAD.