This user’s and maintenance manual refers to VIP4ToolsPro air/oil lubrication system.

This manual should be conserved in such a way that it remains undamaged over time and is readily

available to personnel needing to consult it.

Further copies of this manual, updates or clarifications can be obtained by directly contacting the

Technical Sales Office at Dropsa.

The manufacturer reserves the right to update the product and/or the user’s and maintenance manual

without the obligation to revise previous versions. It is however, possible to contact the Technical Sales

Office for the latest revision in use, or to consult our web site at http://www.dropsa.com.

The use of the equipment referred to in this manual must be entrusted to qualified personnel with a basic

knowledge of mechanics, hydraulics and electrical systems.

It is the responsibility of the installer to use tubing suitable for the system; the use of inadequate tubing

can cause problems with the pump, injury to persons and create pollution.

Loosening of connections can cause serious safety problems; carry out a check before and after

installation and, if necessary retighten them.

Never exceed the maximum working pressure values permitted for the panel and the components

connected to it.

Before any maintenance or cleaning operation disconnect the power supply, close off the air supply and

discharge the pressure from inside the equipment and the tubing connected to it.

Do not subject the panel, the connections, the tubing or parts under pressure to violent impacts; damaged

tubing or connections are dangerous and should be immediately replaced.

After long periods of inactivity check air tightness of all parts subjected to pressure.

Personnel must use personal protection equipment, clothing and tools adequate for the location and the

use of the panel both during its operation and during maintenance operations.

The panel, and any accessories mounted on it, should be carefully checked immediately on receipt and in

the event of any discrepancy or complaint the Dropsa SpA Sales department should be contacted without

delay.

Dropsa SpA declines to accept any responsibility for injuries to persons or damage to property in the event of the

non-observance of the information presented in this manual.

Any modification to component parts of the system or the different destination of use of this system or its

parts without prior written authorization from Dropsa SpA will absolve the latter from any responsibility for

injury to persons and/or damage to property and will release them from all obligations arising from the

guarantee

2. GENERAL DESCRIPTION

The VIP4ToolsPro panel is to be utilized for:

- Tool and cutter griding

- Boring

- Broaching

- Rollforming

- Chains

- Mono and bi-rails conveyors

- Pipes bending

- Gear cutting

- Tapping

- Drilling

- Milling

- Bending

- Punching

- Band and circular sawing

Designed for high performance at a low cost, it is distinguished by its compactness.

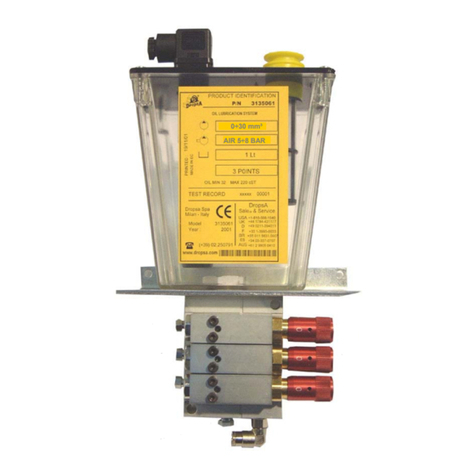

The system comprises a pneumatically controlled mini-pump and the mixer base. The mini-pump can be

manually regulated to cover a wide range of needs (0-30 mm³). The modularity of the system allows

extreme versatility by allowing different numbers of base mixing-manifolds to be installed accordingly.

3. PRODUCT IDENTIFICATION

A yellow plate showing the product code and the basic characteristics is mounted on the front of the oil

tank.