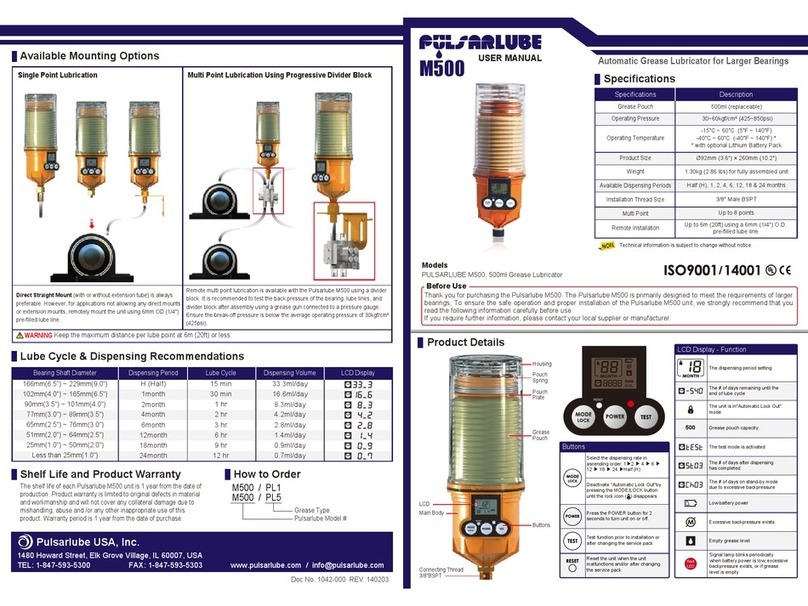

Pulsarlube USA, Inc

1480 Howard Street, Elk Grove Village, IL 60007, USA

Tel: (847) 593-5300 Fax: (847) 593-5303

www.pulsarlube.com

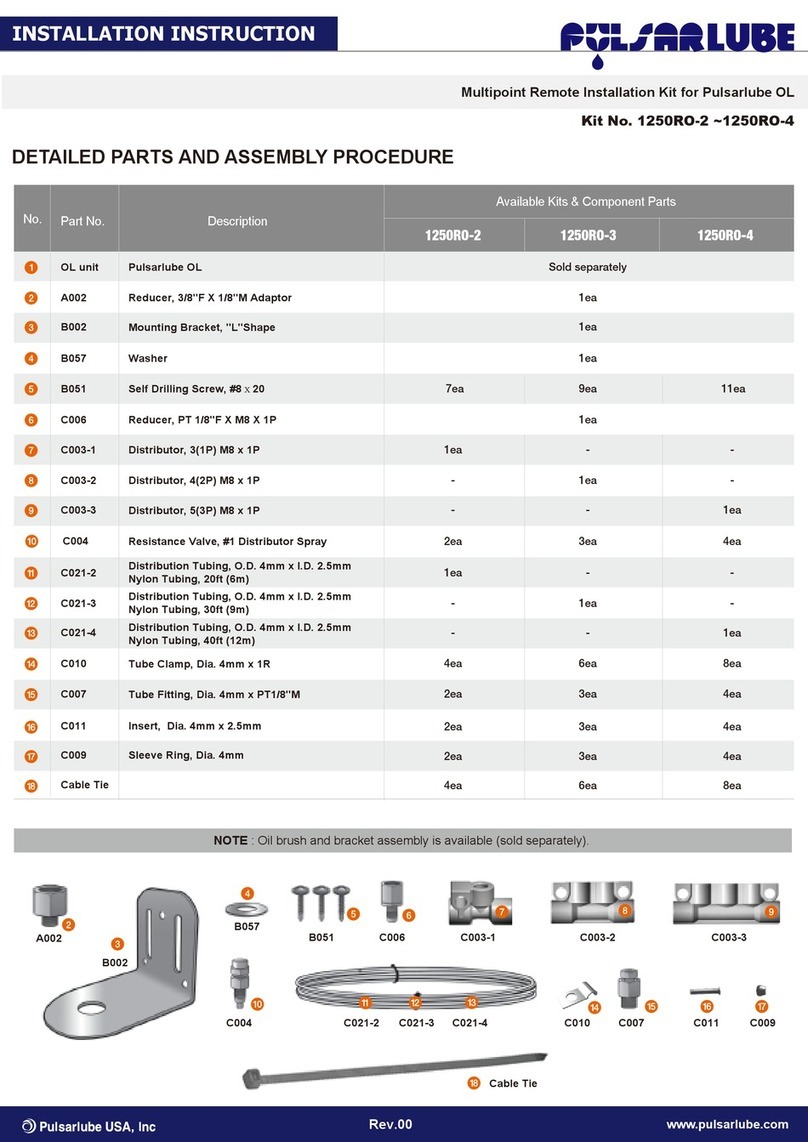

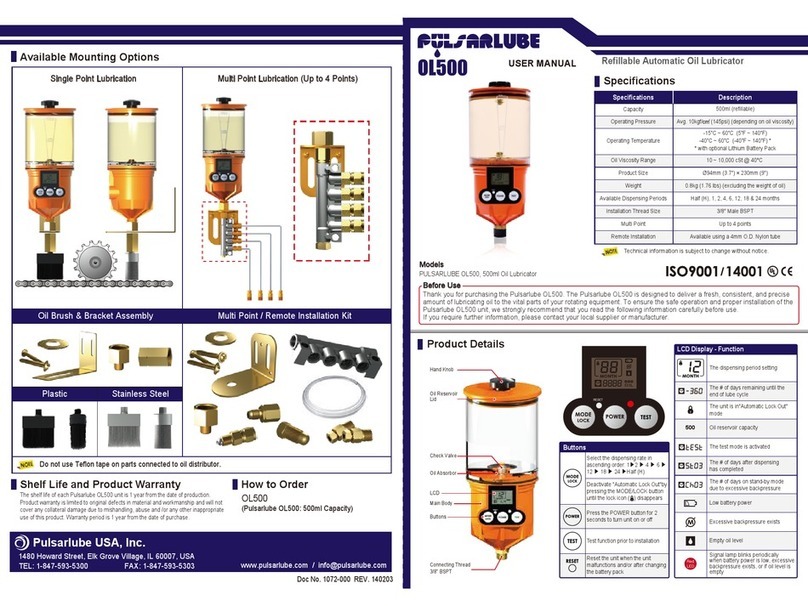

Multi-Point Installation

Install the mounting bracket (3) at a proper

location using screws (8) to allow for easy

installation and filling of oil.

Install the lubricator using the adapter (2),

washer (4), and reducer (5).

Remove the oil reservoir lid and fill the

cartridge with oil to the 500ml level on the

label. After closing the lid, turn the knob on the

lid counter clockwise to open the vent and

relieve vacuum pressure.

Press the “TEST” button for 2 seconds to run

test mode. Confirm that the unit is dispensing

oil properly.

Assemble the reducer (5) and the distributor

(6). The distributor must be installed near the

lubricator.

Connect one end of the tubing to the

resistance valve (7) and the other end of the

tubing to the fitting connector (11). Assemble

the insert (12) and sleeve ring (13) in order, as

shown in the circled image on the left. (If an oil

brush and bracket assembly is to be used,

connect brush to a fitting connector (11) at the

end of lube line using an appropriate socket.)

Use the tube clamps (10) and screws (8) to

affix the tubing (9) to a wall.

Apply PTFE Tape around the thread on fittings

(2) and (11) and on the tip of the lubricator. Do

not use PTFE Tape on parts (5), (7), or (9).

Output volume may vary depending on oil

viscosity, length of lube line, ambient

temperature, etc.

For oils below ISO VG 100, place the oilers below the

lube points and twist the lube lines a couple of times

to avoid oil leaks caused by gravity.

For oils below ISO VG 100 –OL500 products should be

installed below the lube points.

Note : All parts above are Metric thread.