4.4 Oil Tank and Dispensing Valve

The oil tankmust be installed with the hose connection at the lowest point.

The golden ventilation of the tank must be at the highest point, so that no

oil can escape during driving.

To refill the system, a t-connector is placed between oil tank and

dispensing valve (tube has to be cut). The end cap, located at the end of

the filler pipe, needs to be attached. The removable end cap should be

placed in an accessible area, so refilling can be done easily. The oil flow

direction is marked with an arrow on the dispensing valve. The tube

connectors can be removed by pushing the black locking edge.

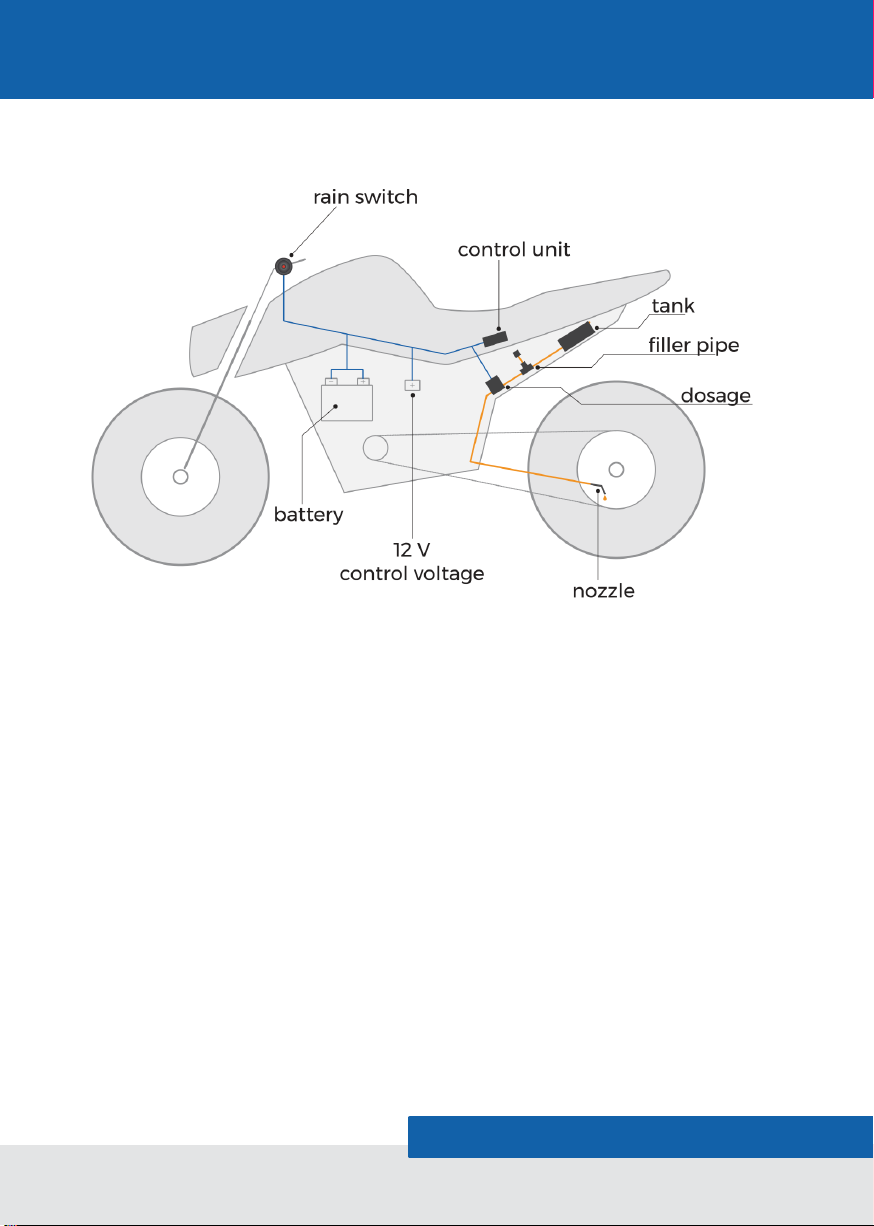

4.5 Electrics

The MOFESSOR is delivered completely wired and tested. Don’t

connect/disconnect the plugs in energized condition.

Steps for the electrical installation:

1. Chose installation place for the control unit

2. Connect dispensing valve to the control unit

3. Place switch for rain-mode activation on the motorbike and

connect the switch to the control unit

→Avoid placing the cable of the switch close to the ignition

Warning: The wire connection at the backside of the switch is not made to

be bent forcibly. The switch will break and this is no issue of warranty. We

recommend laying the M8 connector side of the cable through the motorbike

and not the switch. Please mount washer and nut before. The cable on the

backside of the switch needs to be mounted completely traction-free,

especially with the handlebar at maximum steering angle.