- 7 - 951-181-016

Version 06

EN

Table of contents

Table of contents

EU Declaration of conformity following ATEX directive 2014/34/EU,

annex X ..................................................................................................................2

UK Declaration of Conformity following to Regulation the Equipment and

Protective Systems Intended for Use in Potentially Explosive Atmospheres

Regulations 2016 (2016 No. 1107)....................................................................3

Explanation of symbols, signs and abbreviations...............................................9

1. Safety instructions...................................................................... 11

1.1 General safety instructions..................................................................11

1.2 General behaviour when handling the product.................................11

1.3 Intended use..........................................................................................12

1.4 Foreseeable misuse..............................................................................12

1.5 Modifications of the product................................................................12

1.6 Painting..................................................................................................13

1.6.1 Painting of plastic parts........................................................................13

1.7 Notes related to the CE marking.........................................................13

1.8 Prohibition of certain activities............................................................13

1.9 Inspections prior to delivery ................................................................13

1.10 Other applicable documents................................................................13

1.11 Markings on the product......................................................................14

1.12 Notes related to the UKCA marking ....................................................14

1.13 Notes related to the type identification plate.....................................14

1.14 Persons authorized to operate the pump ..........................................15

1.14.1 Operator.................................................................................................15

1.14.2 Specialist in mechanics ........................................................................15

1.14.3 Specialist in electrics ............................................................................15

1.14.4 Specialist for maintenance and repairs in potentially

explosive atmospheres.........................................................................15

1.15 Briefing of external technicians...........................................................15

1.16 Provision of personal protective equipment......................................15

1.17 Operation...............................................................................................16

1.18 Emergency stopping.............................................................................16

1.19 Transport, installation, maintenance, malfunctions, repair,

shutdown, disposal...............................................................................16

1.20 Initial commissioning / daily start-up.................................................18

1.21 Cleaning .................................................................................................18

1.22 Special safety instructions regarding explosion protection .............19

1.23 Expiry of the ATEX approval.................................................................20

1.24 Explosion protection marking..............................................................20

1.24.1 ATEX marking T6...T5...........................................................................20

1.25 General residual risks...........................................................................21

1.26 Residual risks ATEX...............................................................................22

2. Lubricants................................................................................... 24

2.1 General information .............................................................................24

2.2 Selection of lubricants..........................................................................24

2.3 Material compatibility...........................................................................24

2.4 Temperature characteristics................................................................24

2.5 Lubricants in explosive atmospheres .................................................25

2.6 Ageing of lubricants..............................................................................25

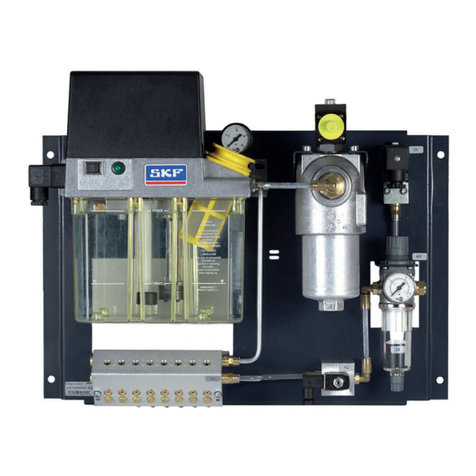

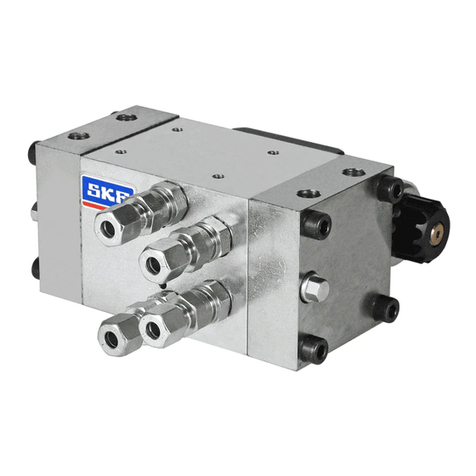

3. Overview, functional description ................................................ 26

4. Technical data ............................................................................. 29

4.1 Mechanics..............................................................................................29

4.2 Nominal output volumes .....................................................................30

4.2.1 Output diagram.....................................................................................30

4.3 Tightening torques ...............................................................................31