10

- I

-

–

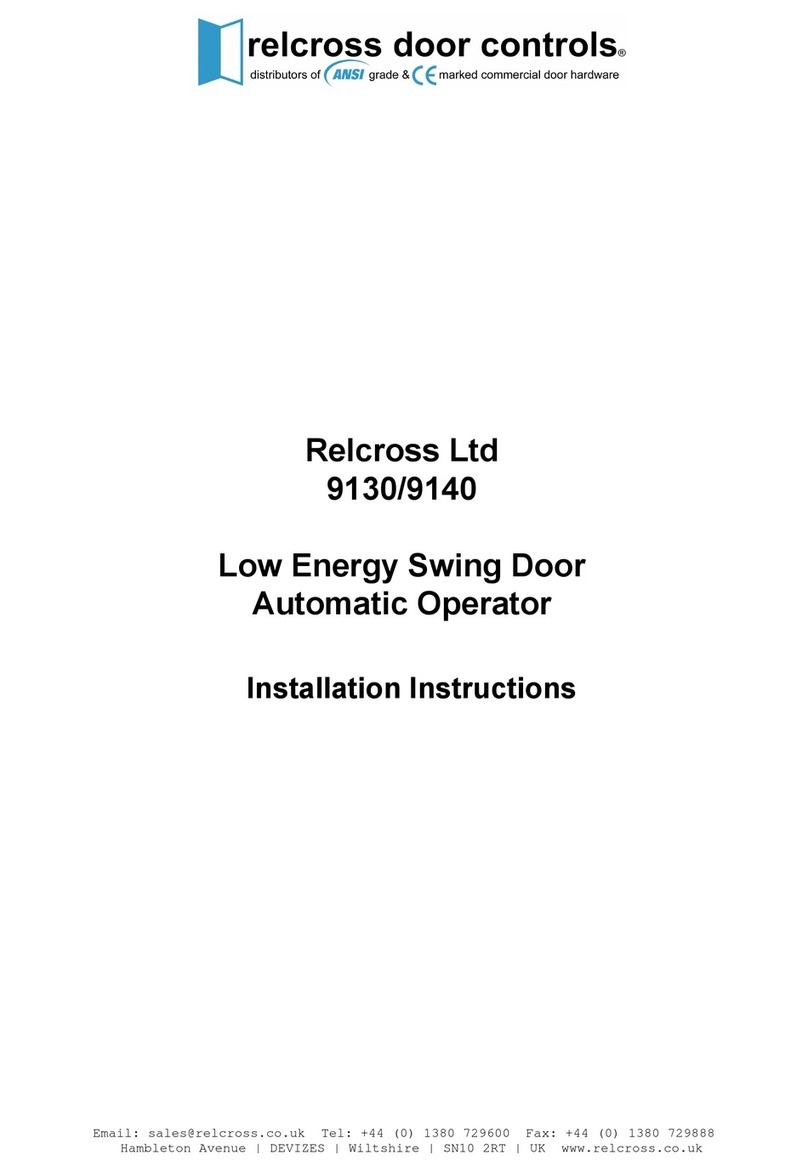

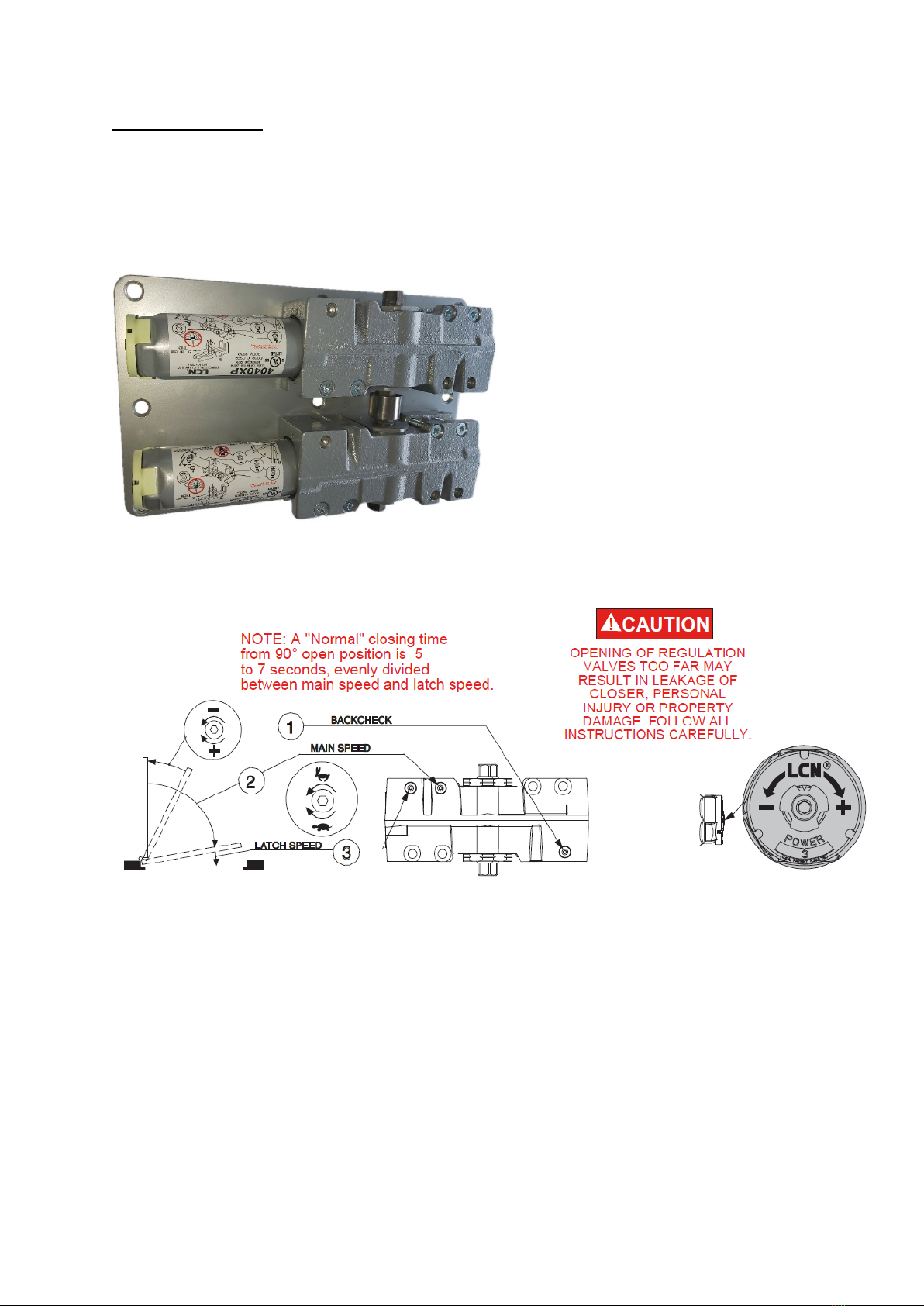

All LCN door closers have a minimum of 3

All closer mechanisms equipped with a ‘delay

valve on the reverse side of the mechanism which must be screwed in fully when the closer is to be

necessary ability to close the door into the frame (you can increase spring power with a simple Allen

key adjustment). Once you are happy with this adjust

Final adjustme

to the closer.

5 – 7 seconds from 90° open to fully closed.

-

When you are happy the closer is installed in accordance with the template and the closer arm has

the necessary pre-

required:

, is located on the end of the spring tube (5/32 Allen key). It is used to

adjust the spring’s power (force to close the door). Clockwise adjustment gives the closer more

-clockwise adjustment gives the closer

reduced closing power and makes the door easier to open.

spaces you must consider combining a number of availabl

-

-

mechanical overhead closer to perform correctly. Similarly, opening windows and doors in connected

-N-Stop arm and

adjust the back check valve (see below) to protect doors and frames.

(*Universal, power adjustable closers only – excludes 2000 series, 3000 series and 4016/4116

closers) (**e)