PH: 866.476.9217 1

I. INTRODUCTION

Fast, safe and economical unloading of covered hopper cars continues to be a problem

at most unloading sites. One of the biggest contributors to this problem is the often

time-consuming and difficult job of opening and closing bottom gates or doors of these

hopper cars. Load compaction, weather conditions, age, abuse, or corrosive or gritty

bulk materials can combine to prevent gate mechanisms from operating smoothly.

Regardless of cause, the costs associated with the problem are significant. Delays in

emptying the hopper cars means slow car turnaround, increased demurrage costs, and

interrupted production schedules. Even more importantly, the chance of worker injury is

high since at many unloading sites, clumsy or dangerous makeshift tools are used

during the “fight” to open a stubborn gate.

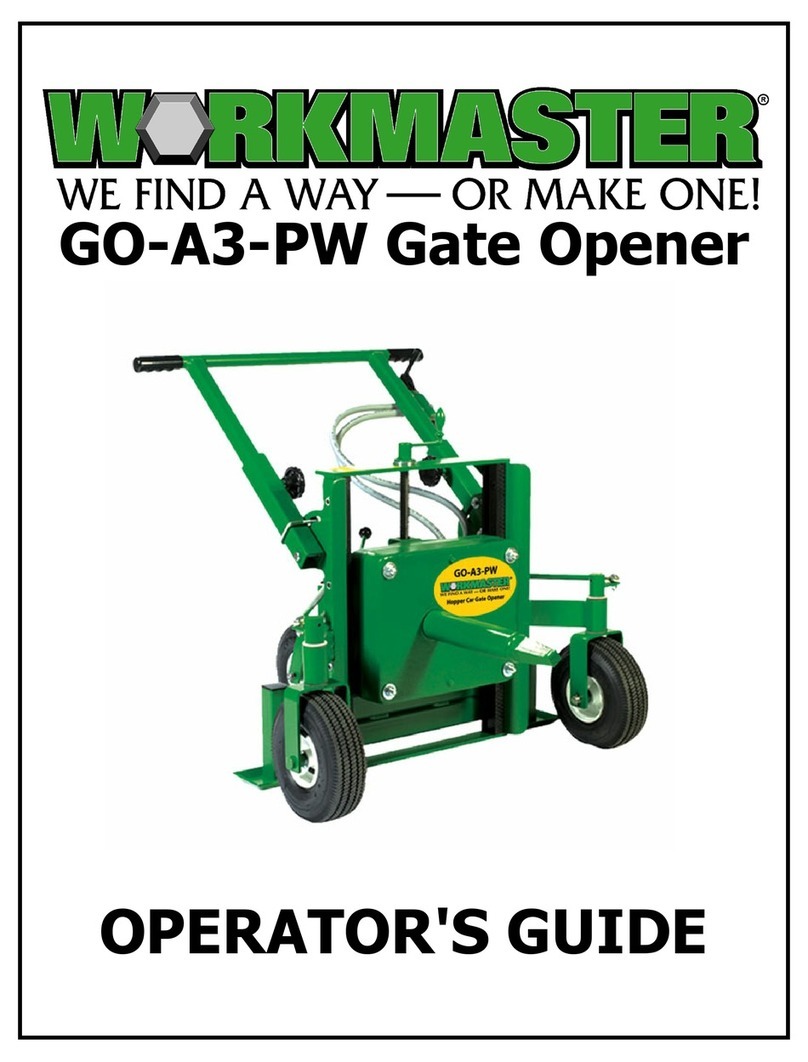

To meet our commitment of “WE FIND A WAY – OR MAKE ONE®”, WORKMASTER

has developed a line of Hopper Car Gate Openers and accessories which provide a safe,

efficient and economical solution to the problem of opening easy, medium and hard-to-

open hopper car gates.

There are pneumatic, electric and manual units available producing up to 13,000 ft-lbs

of torque eliminating the need for "cheater” bars, sledge hammers, jacks, and other

improper tools sometimes used on this difficult job.

This Operator's Guide details the specifications, operation, maintenance, and safe use

of the GO-M04 Hopper Car Gate Opener. Experience has shown that the GO-M04

Opener should be used on easy-to-open car gates. However, the same experience

demonstrates that total satisfaction in use depends on attention to detail in operating

and maintaining the unit.

The GO-M04 Gate opener uses a geared action to open or close hopper car gates with

a continuous 360° rotation in either clockwise (CW) or counter-clockwise (CCW)

direction. Input and output rotation directions are the same. (EXAMPLE: Clockwise input

rotation using the ratchet wrench creates clockwise output rotation on the Capstan

Drive Fitting.)

All persons involved in the operation and maintenance

of this equipment should be thoroughly familiar with

the contents of this manual.