Anti-Grounding Plate

TIME

DELAY

EXIT

LOOP

LMT

REVERSE

LOOP

REV SENSE

OPEN

REV SENSE

CLOSE

1

ON

2 3 41

ON

2 3 4 5 6 7 8

NC

NO

P8 P7P6

4404-010

20 19 18 17 16 15 14 13 12 11 10 987654321

94109410

1

2

5

6

11

13A

13B

13E

25

16

17

U

L1 L2/N B- B+

VWPE PE

Mode

EPM

1.0

PE

SCM series

basic I/O control

115 VAC Convenience Outlets

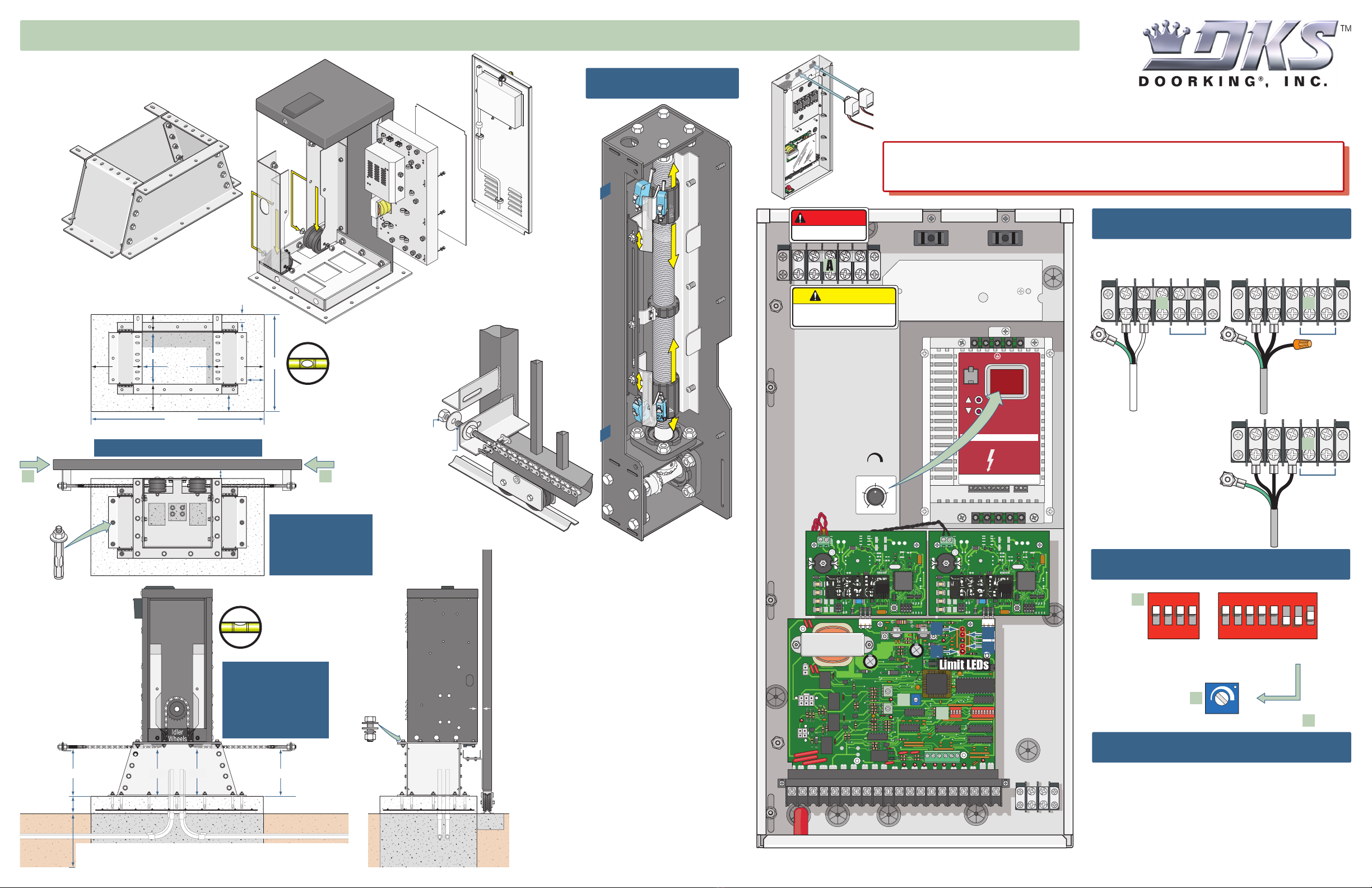

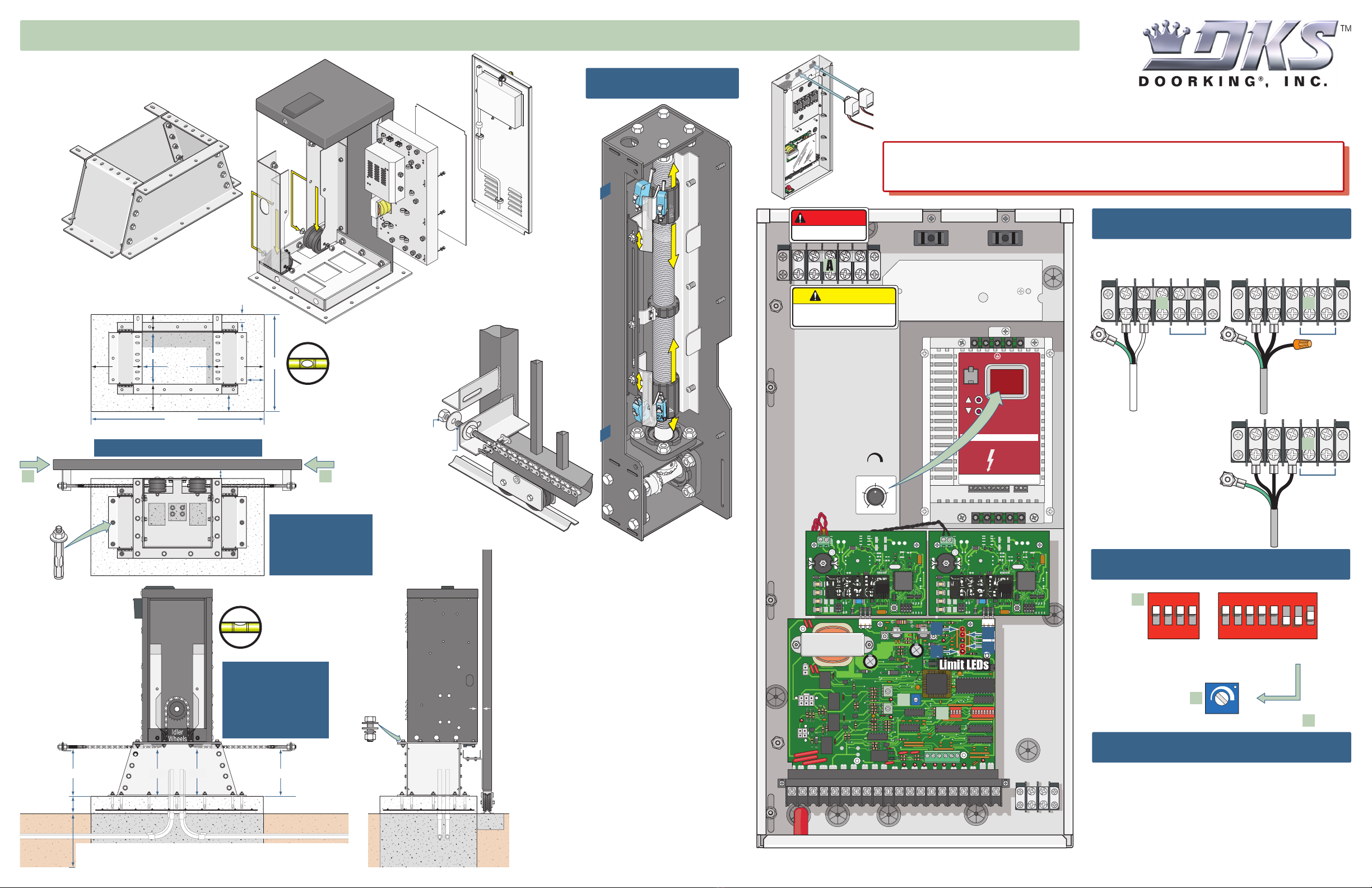

DO NOT power up and

cycle the operator until

the “DIP-Switches” and

the “Limit Switches”

have been adjusted.

Damage could occur to

the gate and operator.

Opening

direction

OFF setting.

Opening

direction

ON setting.

Tip: It is recommended that a surge suppressor be installed on the high voltage

power lines.

GATE OPERATOR MUST BE PROPERLY GROUNDED!!

CAUTION

High Voltage AC input power MUST MATCH

the operator specifications or DAMAGE will

occur and VOID the warranty!

VERIFY Input AC power MATCHES your

specific operator power BEFORE wiring!

EXIT

LOOP

LMT

REVERSE

LOOP

REVSENSE

CLOSE

P8 P7

P6

4404-010

12

43

12

43

12

43

Electronic Box

Power safety and opening devices

that require 115 VAC power.

Two 115 VAC Convenience Outlets

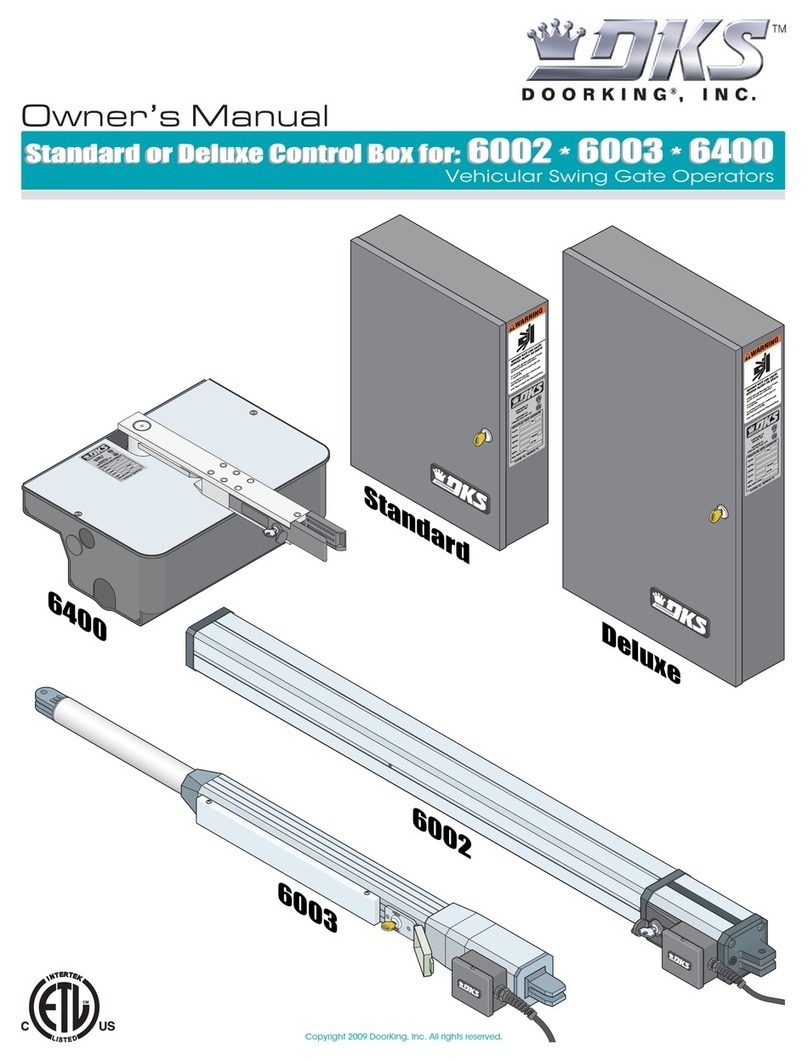

Model 9200 is intended for installation only on sliding gates used for vehicles.

Pedestrians must be supplied with a separate access opening. For safety and installation instructions,

please refer to the Installation/Owner’s manual.

See reverse side

See reverse side to wire main terminal.

With power OFF, push and hold the

lock plate down where shown to

adjust the Open and Close limit nuts.

After adjusting the limit-nuts, be sure

that the lock-plate is engaged in the

slots on the limit-nuts to prevent them

from rotating.

The slow-down limits on all models

but the 9210 will move up or down

3/4 inch. DO NOT remove the

slow-down limit assembly from the

3/4 inch slot and re-attach it in the

longer slot on the partial open

adjustment rail to gain further

adjustment. This will cause mechani-

cal damage to the switch assembly

when the operator is activated.

Turn power ON and activate the gate

operator. Re-adjust the limit nuts as

necessary for full-open and full-close

gate travel. After you are satisfied with

the gate limit settings, the speed

control knob can then be adjusted on

all models but the 9210 to personal

preference.

4” Min.

Pad depth is determined by soil conditions and local building codes.

Minimum depth is 18 inches. Reinforced concrete recommended.

Concrete Pad

Wire

Mesh

3/4”conduit with

sweeps recommended.

Clear Plastic Electronic Box Cover

1

2

3

QUICKSTART “BASIC” GUIDELINES FOR MODEL 9200 “FULL OPEN”: MOUNTED ON THE PEDESTAL MOUNTING STAND

120 Glasgow Avenue

Inglewood, California 90301

U.S.A.

Copyright 2013 DoorKing, Inc. All rights reserved. 9240-066-E-2-13

Plug-In Loop Detectors

Not included - Refer to the Installation/Owner’s manual AND

Loop Information Manual (available from www.dkaccess.com)

for more information on loops and plug-in loop detectors.

Important Note: DoorKing highly recommends that loops and

loop detectors are installed with this slide gate operator. A loop

detection system will preventing the gate from automatically

opening or closing on a vehicle when it is in the gate’s path.

High Voltage Connection

DIP-Switches

Limit Switches

1. Opening Direction

2. ON

3. ON

4. OFF

5. OFF

6. OFF

7. OFF

8. OFF

1. OFF

2. OFF

3. OFF

4. OFF

Auto-Close Timer

Chassis

Ground

DANGER

HIGH VOLTAGE!

1

ON

2 3 4 5 6 7 8 1

ON

2 3 4

SW 1 and 2 are Upside-Down on Circuit Board.

123

TIME

DELAY

A

B

D

C

C C

B

D

1 ft/s

.5 ft/s

0 ft/s 2 ft/s

1.5 ft/s

Limit LEDs

Plug-In Loop

Detector Plug-In Loop

Detector

MinMax

Speed

Push Push

Lock-Plate

Limit Nut Limit Nut

1

2

Slow-Down Limit

Slow-Down Limit

1A

2A

Partial Open

Not Used

1

2

2A

1A

Adjust 1 to 23 sec.

1 Limit

Switch

2 Limit

Switch

Check polarity of Three Phase:

Position the gate half way open.

Give open command and while

gate is opening, activate the

appropriate limit switch with your

finger. Gate should STOP. If it does

not, activate the other limit switch.

If this STOPS the gate, AC power

wires must be changed (Reverse

the connection of any 2 wires and

re-check limits).

Partial Open Adjustment Rail

208/230 VAC

THREE Phase

Chassis

Ground High

Voltage

AC Input

Wire

Hot

115 VAC Output

HotHot

208/230 VAC

SINGLE Phase

Chassis

Ground

High

Voltage

AC Input

Wire

Hot

115 VAC Output

Hot Hot

Use only two legs

of the incoming

3-phase power.

Chassis

Ground

High

Voltage

AC Input

Wire

Hot

115 VAC Output

Neu

115 VAC

SINGLE Phase

White - Neutral

Black - 115 VAC Hot

Green - Chassis

Ground

SW 1SW 2

AA

A

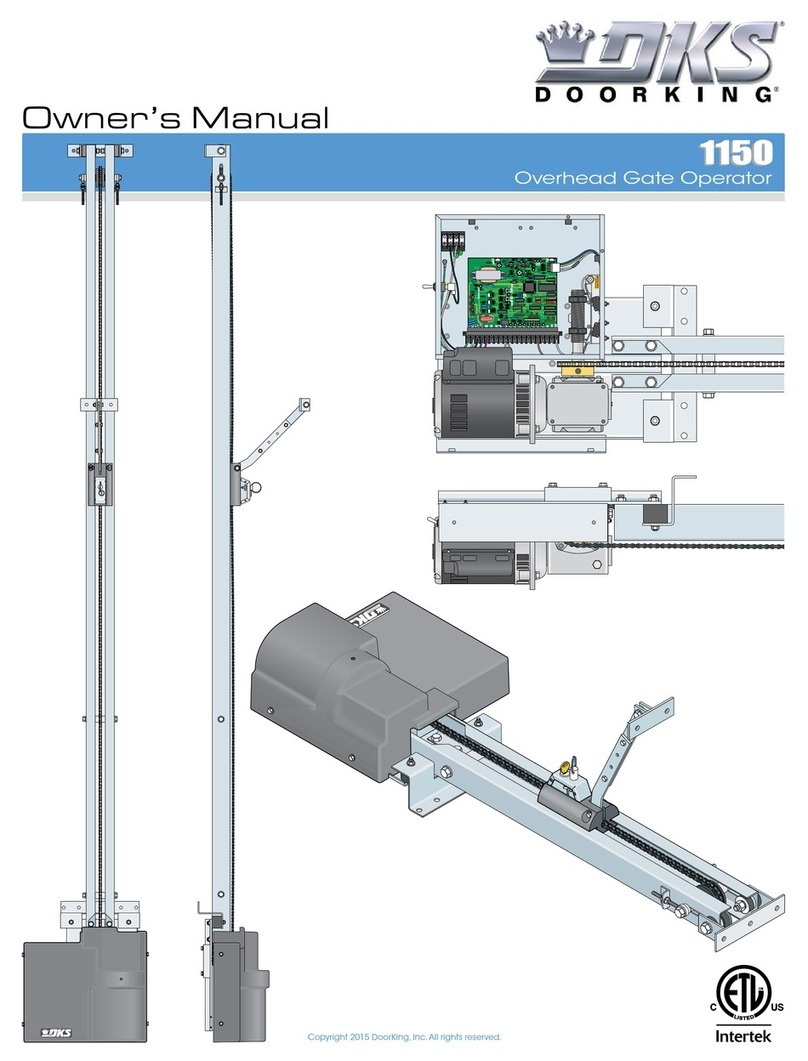

Operator MUST be parallel to gate!

Chain brackets MUST

align with idler

wheels so chain

stays parallel to gate!

Remove the 3 locknuts inside the

electronic box to swing box open.

Gain Access Inside Operator

Move the idler wheels to the lower position.

Fits on All 9200 Models.

Standard with 9230, 9235, 9240 and 9245 Models

1/2

Attach pedestal stand with

sixteen (16) 1/2” x 3” sleeve

anchors (not supplied) after

concrete pad has been

poured and has cured.

Bolt operator to

pedestal with

hardware supplied

in pedestal kit.

Manual

crank in

stored

position.

Caution:

Never

attempt to

manually

operate the

9200 until

you have

verified that

power has

been shut-off.

Connect

Chain to

the Gate

Chain nut

and chain bolt

should not protrude

past gate frame. The chain

should sag no more than one

(1) inch per 10 feet of travel. Do not

over tighten the chain.

Chain

Nut

Chain Bolt

Option 2

Master Link

Option 1

Gate

Frame

1”

Assemble Pedestal

Mounting Stand

Concrete Pad

Dimensions,

Pedestal

Mounting

Stand and

Conduit

Positions

1.75”

11.75”

4”

6.25” 4”

4”

Concrete Pad

Conduit

Area Concrete pad

MUST be level!

Idler

Wheels

Gate

Chain

Bracket

Conduit

Chain

Bracket

Chain

Bracket

Idler Wheels

Chain

Configuration

Concrete Pad

Electronic Box

DoorKing

Part Number

9200-135

See instruction

sheet with

pedestal kit

for assembly.

Chain

Tray

Washer

12 Sets

Washer

Lockwasher

Operator Base Plate

Gate

“Optional” Chain

Tray Kit:

Recommended for

gates longer than 20

ft. to support the

weight of the chain.

DoorKing offers a

chain tray and

supporting brackets

in 10 ft. sections to

fit any length gate

(DoorKing Part

Number 2601-270,

10 Ft. section). See

instruction sheet

with chain tray kit

for installation.

Chain brackets MUST

be mounted so the

chain remains the

same height as it is

on the idler wheels!

15.75”11.75”

11.75”

10.5” 10.5”10.5” 10.5”

1”

39.25”

22”

Top

Views

Side

Views

Pedestal mounting stand

MUST be level!

Idler Wheels

Speed Control Knob

On all models but 9210.