9

Complete disassembly is not recommended. Return the unit to an authorized dealer for

total disassembly and/or repair.

All maintenance or disassembly should take place on a flat, clean work surface

covered with towels or wipers so as to have a clean space for the disassembled parts.

Inspect each part during disassembly for wear, scratches, and cuts. Discard the worn or damaged

parts and replace with new factory authorized parts. See parts drawings on pg16-20.

O-rings are sensitive to sharp edges. Inspect closely for cuts or damage. A small cut will cause

a leak. When assembling or disassembling O-rings, use hydraulic fluid as a lubricant to help

disassembly or installation.

When disposing of hydraulic parts or components observe all federal, state, and local guidelines.

IF YOU HAVE QUESTIONS REGARDING THE REPAIR AND MAINTENANCE

OF THIS TOOL CONTACT RELIABLE EQUIPMENT AT 800-966-3530

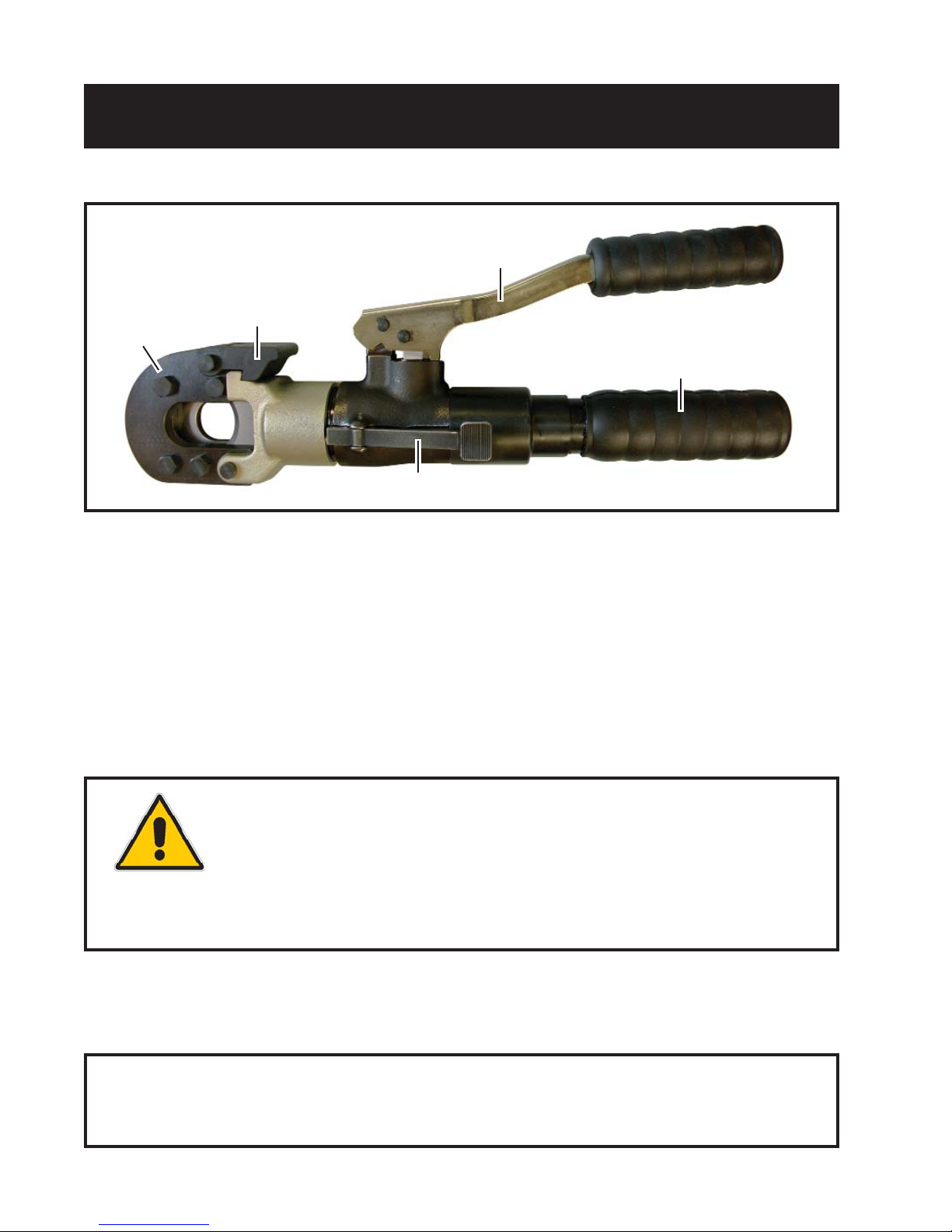

GENERAL MAINTENANCE

DAILY MAINTENANCE

The life, reliability, and safety of the tool is dependent on proper maintenance.

Clean and inspect all surfaces including head, latch mechanism, blade, ram, body and handles.

WARNING blade, head and handles may cut or pinch. Please use extreme caution.

Worn or damaged parts (i.e. chipped or cracked blade) may malfunction during operation,

causing more extensive damge to the tool and/or severe injury to the operator or bystander..

All parts must be replaced with new parts if signs of wear or damage are evident.

Keep Label Set clean and legible. Replace decals when necessary.

BEFORE USING THIS PRODUCT

READ THE SAFETY WARNINGS

and recommended practices described

in the manual. Failure by the operator to

read and fully understand the warnings

will leave this person unqualifi ed to use

and operate the tool.

Failure to observe all warnings and instructions could result

in property damage, severe personal injury, and/or death.

R

WARNING

Hardened metals may fly when severed

Take necessary precautions. Wear

safety glasses do not cut live

conductors. Keep fingers away from

cutting blades and moving parts.

Secure latch before operating tool

Failure to secure latch can result in tool

damage and personal injury.

NOTE:

Warning, Caution, & Danger Labels

are now on a single label # TMP4x1

Hardened Metals Label is # 20-CSL