Model F1FR Quick Response Concealed Pendent Sprinklers

Installation Wrench: Model RC1 Sprinkler Wrench

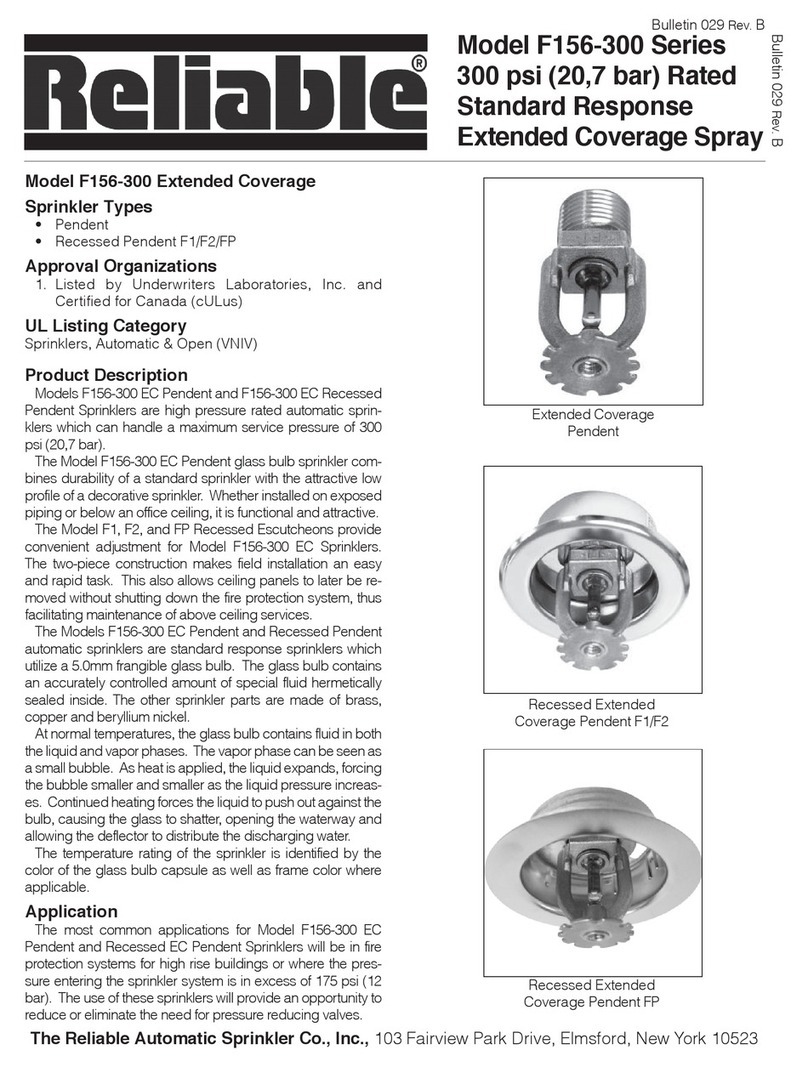

Technical Data:

Nominal

Orifice

“K” Factor Thread

Size Model

Temp. Rating Max.

Ambient

Temp

Bulb

Color Approvals

Sprinkler

Identification

Number(SIN)

US Metric Sprinkler Cover

½” (15mm) 5.6 80 ½” NPT F1FR 135°F/57°C 135°F/57°C 100°F/38°C Orange 1, 2 RA1414

½” (15mm) 5.6 80 ½” NPT F1FR 155°F/68°C 135°F/57°C 100°F/38°C Red 1, 2, 4(1) RA1414

½” (15mm) 5.6 80 ½” NPT F1FR 175°F/79°C 165°F/74°C 100°F/38°C Yellow 1, 2 RA1414

½” (15mm) 5.6 80 ½” NPT F1FR 200°F/93°C 165°F/74°C 100°F/38°C Green 1, 2 RA1414

(1) For VdS only = 155°F/68°C Norbulb and 1/2” [12,7mm] adjustment.

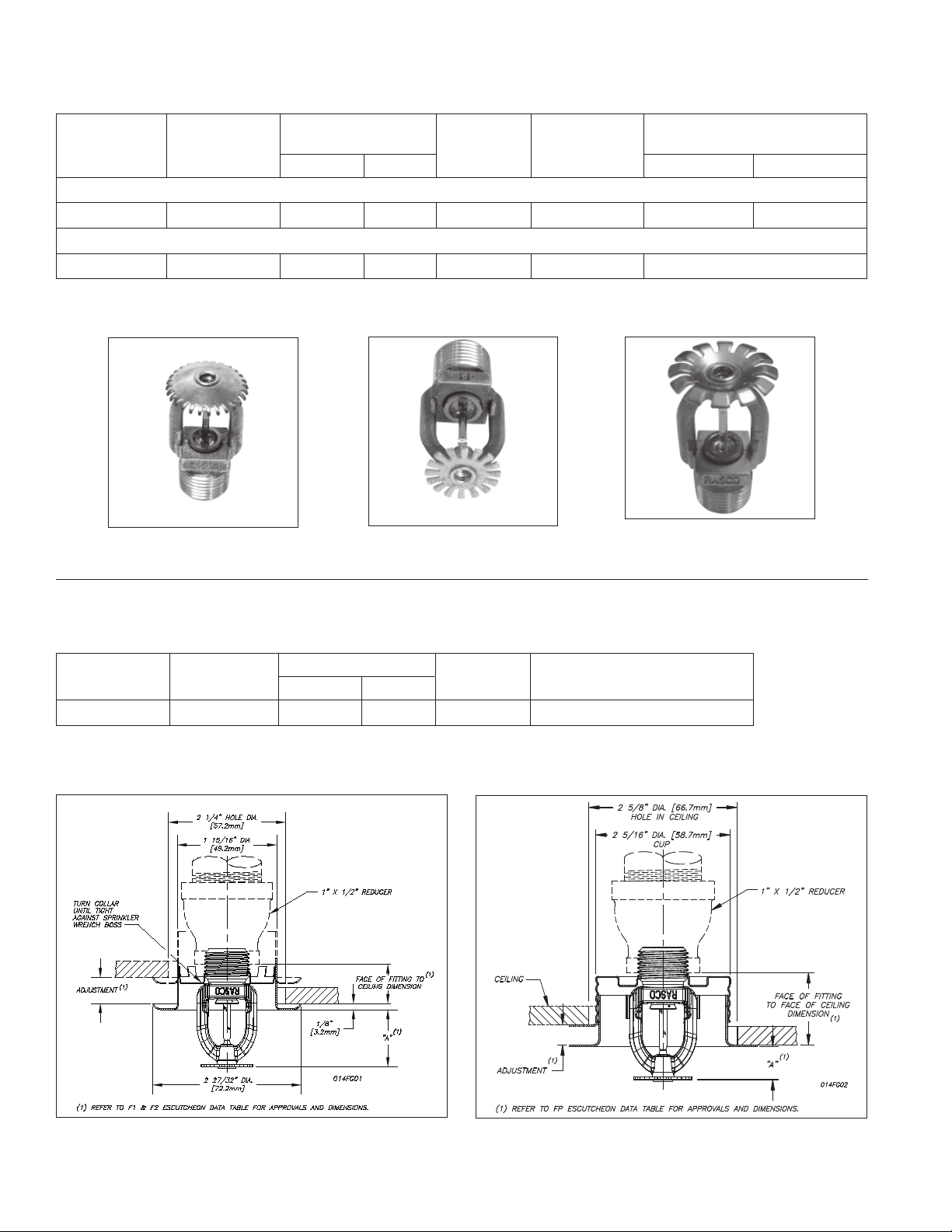

Figure 1 Figure 2

Installation Aid

A protective cap is included for use during installation.

Important: The F1FR 56 Sprinkler with Model CCP cover

plate is not an FM Approved combination.

Installation

Quick response sprinklers are intended for installation

as specified in NFPA 13. Quick response sprinklers and

standard response sprinklers should not be intermixed.

The Model F1FR 56 Recessed Quick Response Sprin-

klers are to be installed as shown. The Model F1 or F2 Es-

cutcheons illustrated are the only recessed escutcheons

to be used with the Model F1FR 56 Sprinklers. The use

of any other recessed escutcheon will void all approvals

and negate all warranties.

When installing Model F1FR 56 Sprinklers, use the

Model D Sprinkler Wrench. Use the Model GFR2 Wrench

for installing F1FR 56 Recessed Pendent Sprinklers. Any

other type of wrench may damage these sprinklers.

NOTE: A leak tight ½” NPT (R1/2) sprinkler joint can

be obtained with a torque of 8-18 ft-lbs (10,8 - 24,4 N-m).

Do not tighten sprinklers over maximum recommended

torque. It may cause leakage or impairment of the sprin-

klers.

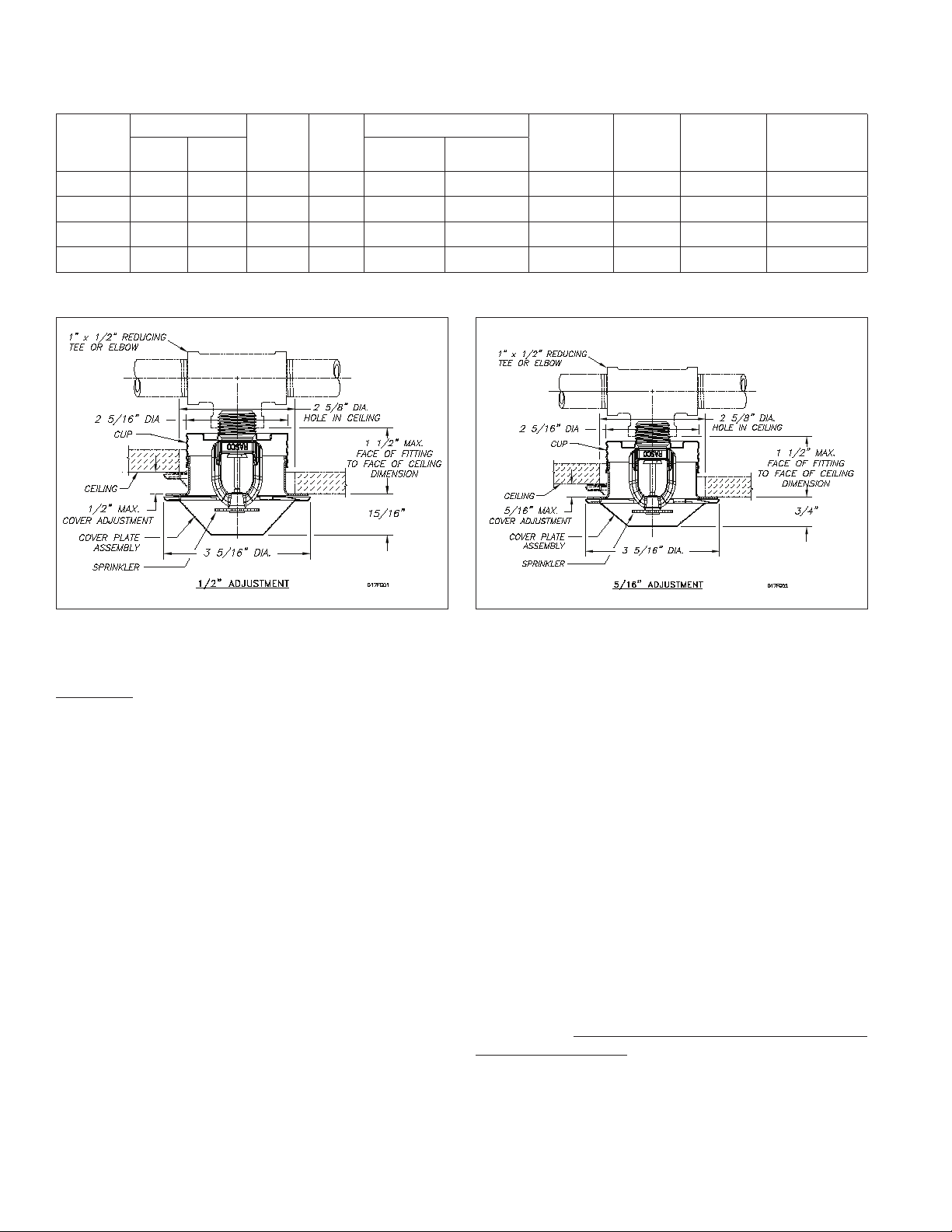

The Model F1FR 56/ CCP Concealed Sprinkler uses the

½” orifice, ½” NPT (R1/2), 135°F (57°C), 155°F (68°C),

175°F (79°C) or 200°F (93°C) Model F1FR 56 Pendent

Sprinkler with a threaded Model CCP cup which is fac-

tory attached to the sprinkler. The assembly is complet-

ed by the installation of the attractive, low profile, 135°F

(57°C) or 165°F (74°C) rated Model CCP push on cover

plate assembly. The cover plate and sprinkler cup as-

semblies are joined using a cover plate skirt with flexible

tabs for threaded engagement. A choice of two cover

plate assemblies provide either ½” (13mm) or 5/16” (8mm)

of cover adjustment.

Do not install these sprinklers in ceiling which have

positive pressure in the space above.

After a 25/8” (67mm) diameter hole is cut in the ceil-

ing, the sprinkler is easily installed with the Model RC1

Wrench. A Teflon* based thread sealant should be

applied to the sprinkler threads only. The Model RC1

Wrench is then used to engage the sprinkler wrenching

surfaces and to install the sprinkler in the fitting. When

inserting or removing the wrench from the sprinkler/cup

assembly, care should be taken to prevent damage to

the sprinkler. DO NOT WRENCH ON ANY OTHER PART

OF THE SPRINKLER. The cover plate is then pushed

onto the cup. Final adjustment is made by hand turning

the cover plate until the skirt flange makes full contact

with the ceiling. Cover plate removal requires turning in

the counter clockwise direction.

4.