Page 8

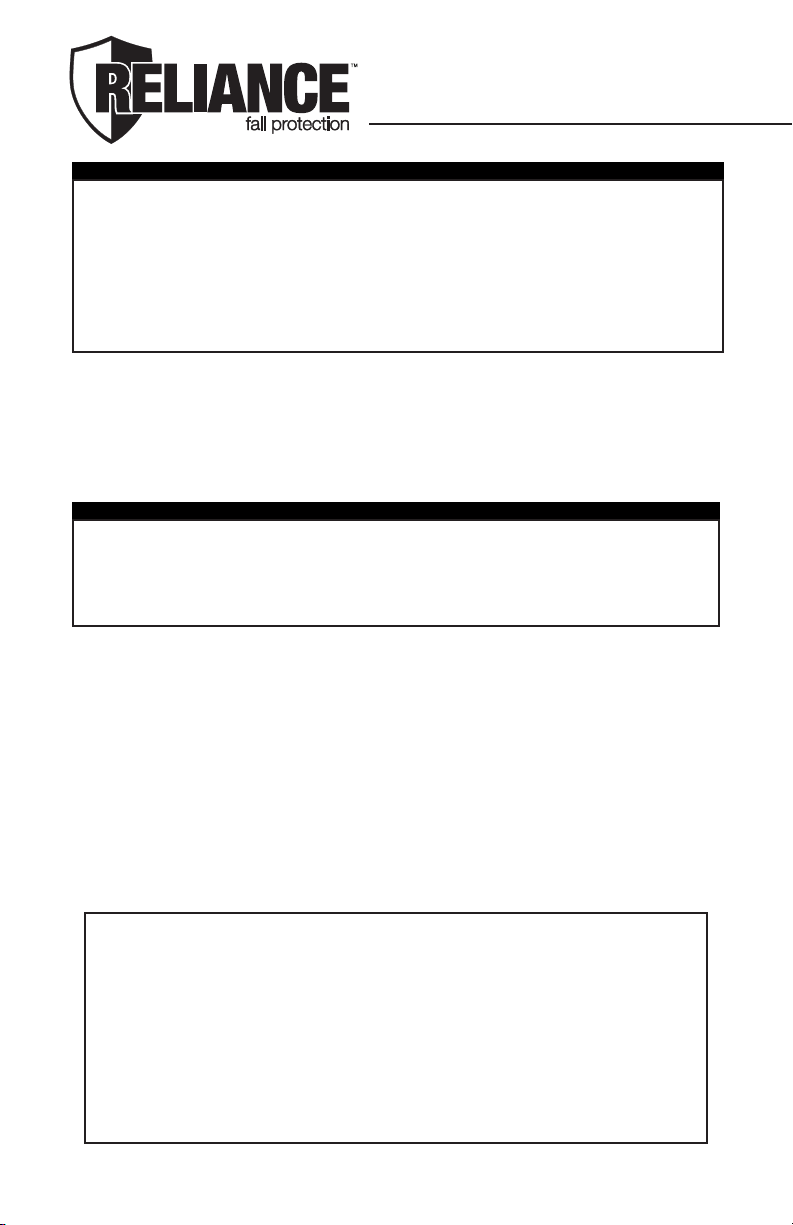

PRODUCT SPECIFICATIONS

Part # Working

Length Line Type Weight Capacity Hook Type Housing

Type

Housing

Dimensions

4015 18’ (5.5m) 3/16” (4.5mm)

galvanized 7 lbs (3.1kg) 400 lbs (181kg) 3006 Pelican

Zn Plate

LDPE over ABS

Plastic

11”L X 6”W X 3”H

(28cm X 15cm X 8cm)

4020 20’ (6.1m) 1” (25mm)

polyester web 8 lbs (3.6kg) 400 lbs (181kg) 3006 Pelican

Zn Plate

LDPE over ABS

Plastic

11”L X 6”W X 3”H

(28cm X 15cm X 8cm)

4030 30’ (9.1m) 3/16” (4.5mm)

galvanized 25 lbs (11.3kg) 400 lbs (181kg) 3007 Swivel

Zn Plate Carbon Steel 15”L X 9”W X 4”H

(38cm X 23cm X 10cm)

4031 30’ (9.1m) 3/16” (4.5mm)stainless 25 lbs

(11.3kg) 400 lbs (181kg) 3008 Swivel

Stainless Stainless Steel 15”L X 9”W X 4”H

(38cm X 23cm X 10cm)

4050 50’ (15.2m) 3/16” (4.5mm)

galvanized

26 lbs

(11.7kg) 400 lbs (181kg) 3007 Swivel

Zn Plate Carbon Steel 15”L X 9”W X 4”H

(38cm X 23cm X 10cm)

4051 50’ (15.2m) 3/16” (4.5mm)stainless 26 lbs

(11.7kg) 400 lbs (181kg) 3008 Swivel

Stainless

Stainless

Steel

15”L X 9”W X 4”H

(38cm X 23cm X 10cm)

4075 75’ (22.8m) 3/16” (4.5mm)

galvanized

48 lbs

(21.7kg) 400 lbs (181kg) 3007 Swivel

Zn Plate Carbon Steel 19”L X 13.5”W X 4.5”H

(48cm X 34cm X 11cm)

4100 100’ (30.4m) 3/16” (4.5mm)

galvanized

44 lbs

(20kg) 400 lbs (181kg) 3007 Swivel

Zn Plate Carbon Steel 19”L X 13.5”W X 4.5”H

(48cm X 34cm X 11cm)

4101 100’ (30.4m) 3/16” (4.5mm)stainless 44 lbs

(20kg) 400 lbs (181kg) 3008 Swivel

Stainless

Stainless

Steel

19”L X 13.5”W X 4.5”H

(48cm X 34cm X 11cm)

4130 130’ (39.6m) 3/16” (4.5mm)

galvanized

48 lbs

(21.7kg) 400 lbs (181kg) 3007 Swivel

Zn Plate Carbon Steel 19”L X 13.5”W X 4.5”H

(48cm X 34cm X 11cm)

4131 130’ (39.6m) 3/16” (4.5mm)stainless 48 lbs

(21.7kg) 400 lbs (181kg) 3008 Swivel

Stainless

Stainless

Steel

19”L X 13.5”W X 4.5”H

(48cm X 34cm X 11cm)

4000020-1 20' (6m) 3/16" (4.5mm)

galvanized

15 lbs

(6.8kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

11"L X 12"W X 4" H

(28cm X 30 cm x 10 cm)

4000030-1 30' (9.1m) 3/16" (4.5mm)

galvanized

17 lbs

(7.7kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

11"L X 12"W X 4" H

(28cm X 30 cm x 10 cm)

4000050-1 50' (15.2m) 3/16" (4.5mm)

galvanized

22 lbs

(10.0kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

12"L X 13"W X 4" H

(30cm X 33 cm X 10 cm)

4000085-1 85' (25.9m) 3/16" (4.5mm)

galvanized

35 lbs

(15.9kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

14"L X 15"W X 4" H

(35 cm X 38 cm X 10 cm)

4000100-1 100' (30.5m) 3/16" (4.5mm)

galvanized

37 lbs

(16.8kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

14"L X 15"W X 4" H

(35 cm X 38 cm X 10 cm)

4008025-1 25’ (7.6m) 1/4” (6.4mm) Dyneema

Rope

17 lbs

(7.7kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

11”L X 12”W X 4” H

(28cm X 30 cm x 10 cm)

4008040-1 40’ (12.2m) 1/4” (6.4mm) Dyneema

Rope

19 lbs

(8.6kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

12”L X 13”W X 4” H

(30cm X 33 cm X 10 cm)

4008080-1 80’ (24.4m) 1/4” (6.4mm) Dyneema

Rope

32 lbs

(14.5kg) 310 lbs (140kg) 3007 Swivel Zn Plate Fiberglass-

Reinforced Nylon

14”L X 15”W X 4” H

(35 cm X 38 cm X 10 cm)

4102050-1 50’ (15.2m) 3/16” (4.5mm)stainless 41.2 lbs

(18.7kg) 310 lbs (140kg) Swivel Carabiner

Stainless

Stainless Anodized

Aluminum

12.5”L X 12.5”W X 6.5” H

(32 cm X 32 cm X 17 cm)

4102130-1 130’ (39.6m) 3/16” (4.5mm)stainless 65 lbs

(29.5kg) 310 lbs (140kg) Swivel Carabiner

Stainless

Stainless Anodized

Aluminum

14.5”L X 14”W X 7” H

(37 cm X 36 cm X 18 cm)

4302020-1 20' (6m) 3/16" (4.5mm) stainless 15 lbs

(6.8kg) 310 lbs (140kg) Swivel Carabiner

Stainless

Fiberglass-

Reinforced Nylon

11"L X 12"W X 4" H

(28cm X 30 cm x 10 cm)

4302030-1 30' (9.1m) 3/16" (4.5mm) stainless 17 lbs

(7.7kg) 310 lbs (140kg) Swivel Carabiner

Stainless

Fiberglass-

Reinforced Nylon

11"L X 12"W X 4" H

(28cm X 30 cm x 10 cm)

4302050-1 50' (15.2m) 3/16" (4.5mm) stainless 22 lbs

(10.0kg) 310 lbs (140kg) Swivel Carabiner

Stainless

Fiberglass-

Reinforced Nylon

12"L X 13"W X 4" H

(30cm X 33 cm X 10 cm)

4302080-1 80' (24.4m) 3/16" (4.5mm) stainless 35 lbs

(15.9kg) 310 lbs (140kg) Swivel Carabiner

Stainless

Fiberglass-

Reinforced Nylon

14"L X 15"W X 4" H

(35 cm X 38 cm X 10 cm)

4302100-1 100' (30.5m) 3/16" (4.5mm) stainless 37 lbs

(16.8kg) 310 lbs (140kg) Swivel Carabiner

Stainless

Fiberglass-

Reinforced Nylon

14"L X 15"W X 4" H

(35 cm X 38 cm X 10 cm)

4400012-1 12' (3.6m) 3/16" (4.5mm) stainless 5.8 lbs

(2.6kg) 310 lbs (140kg) Pelican Swivel

Zinc Plate

Sanoprene Over

ABS

8"L X 5"W X 3.5" H

(20.3 cm X 12.7 cm X 88.9 cm)