Planning the installation

(“55AQUAJET OES and AES SERIES” ONLY):

The Aquajet OES and AES Series pumps were designed specifically for the RV aftermarket and, as a result, should be

compatible with the existing electrical wiring for most RVs. Because these pumps use a lower amperage motor than the

Aquajet ORV and ARV Series, installation is generally simplified. Often times, installation is as simple as removing the

wirenuts connecting the existing water pump and then reconnecting the existing wiring (keeping careful track of polarity) to

the Aquajet pump.

Before installation, however, you should insure that your particular RV does not require any electrical modifications to run the

Aquajet OES/AES, as follows:

1. Determine whether or not your existing wiring can supply 6.5 Amps to the Aquajet ES without generating an excessive

voltage drop or overloading any control component. You should check specifically for three (3) things:

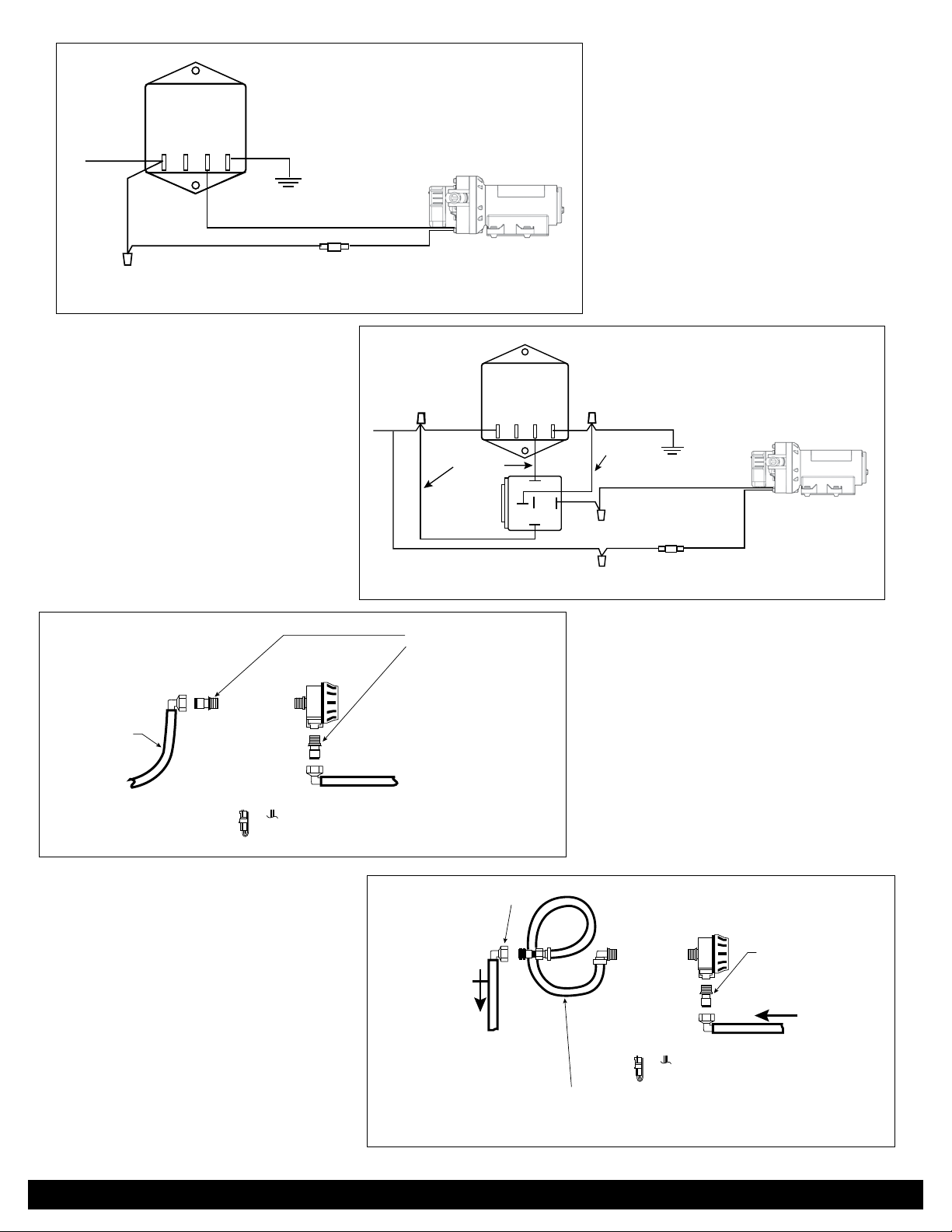

a. Determine whether your RV is currently using an Intellitec pump controller. The Aquajet ES Series is compatible

with most common rated versions (7 Amp, 10 Amp, 15 Amp). However, if you have either a 3 Amp or non-rated

controller, you should procure a 40 Amp rated relay to augment your existing controller. These 40 Amp relays are

available through local automotive stores or through Remco directly (P/N 20-267-6040-REM). If necessary, refer to

Figure 8, page 6 for additional information.

b. Check your RV Owner’s Manual for the recommended fuse rating for the pump branch circuit. If your

recommended rating is rated 10 Amps or more, you can proceed directly with the electrical installation. If your

recommended rating is less than 10 Amps, you should procure a 30 Amp rated relay as referenced above.

If necessary, please refer to Figures 1 and 2, page 4 for additional wiring instructions.

c. If there are two (2) or more switches in your RV that independently control your pump, you may experience

excessive voltage drops in your existing circuitry. Using voltmeter, test voltage at the pump with the pump running

(refer to Figure 1, page 4). With either a fully charged battery or a running generator, you should be getting at least

11 volts at the pump. If not, you should procure a 30 Amp rated relay as referenced above.

2. Determine the optimal location for the Aquajet pump. If possible, plan to position the Aquajet pump horizontally, with

its rubber feet resting on a “floor-like” surface rather than mounted on a wall. Never mount the pump in an area where

gasoline vapors are present, as the motor and heatsink of the speed-controller may get hot (up to 200 F) after extended

running. Locate the Aquajet pump at least one inch away from any wall surface. In most cases, you’ll be able to mount

the Aquajet pump very close to where the old pump was located.

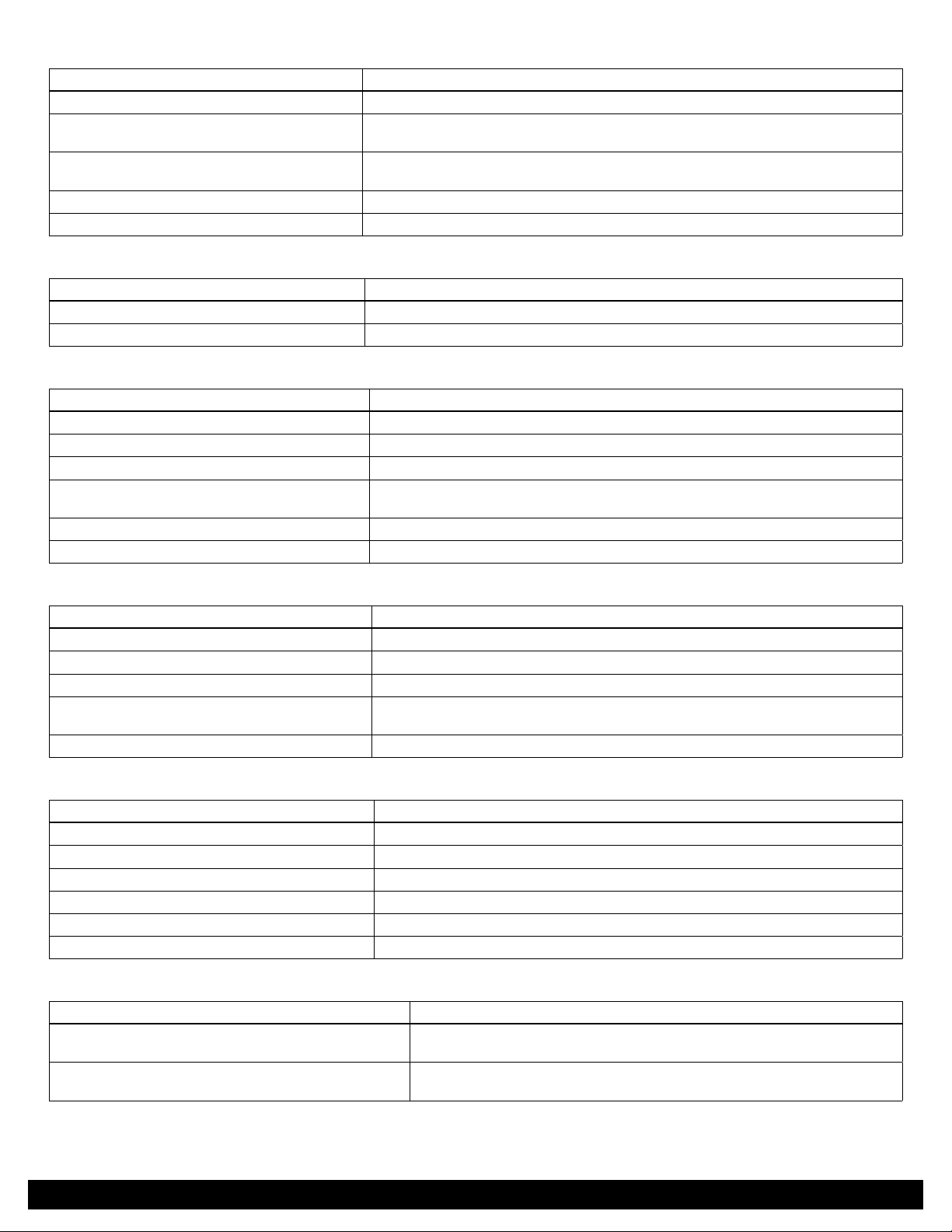

3. Survey the existing plumbing and identify the suction line (i.e. the line going from the water holding tank to the pump).

For the quietest possible operation of the Aquajet pump, you should try to isolate the pump mechanically from your

RV’s typically hard Polybutylene or PEX tubing. If your RV is currently plumbed with soft-walled, reinforced hose (see

Figure 5, page 5), then your system should be perfectly suicient as is. By installing a piece of IAPMO approved cold

water hose (such as ‘Accuflex’ Series 136) between the pump outlet port and your RV’s hard plumbing, you will achieve

the quietest possible pump operation. Remco also oers, as an optional accessory, a 39” long pre-assembled hose with

fittings.

(Remco product number 25-174) that will adapt directly to the Aquajet pump and your existing plumbing. Please refer to

Figures 6 and 7, page 5-6.

Installation

1. Using Voltmeter, determine polarity of the wiring to the existing pump(s). Unfortunately, there is no standardized

color scheme for RV wiring (most RVs, however, seem to use red for the positive lead and black for the negative lead).

Regardless of your specific configuration, positive voltage (12VDC) must be connected to the RED (fused) leadwire of

the Aquajet pump. Reversing this polarity will instantly blow the in-line fuse and may permanently damage the controller.

Mark the positive (hot) RV wire with a piece of tape.

2. Turn power “o” to existing pump(s).

3. Open a faucet, bleed o all existing pressure, then close the faucet again.

4. Disconnect the main power to the pump (either at battery or fuse panel).

5. Remove the wire nuts from the leads to the old pump.

6. Steps 1 and 2 of the earlier ‘Installation Planning’ section should have determined the applicable wiring method. As

appropriate, wire the Aquajet pump as per Figures 1, 2, 3, 4 or 8, pages 4-6.

7. Connect outlet adapters

a. [For old pump outlets connected to hose, as in Figure 5, page 5] Insert O-ringed end of (Qest) threaded adapter

into outlet port (marked with arrow pointing away from pump) of the Aquajet pump. Lock fitting in place by pushing

down retainer slide.

b. For old pump outlets directly connected to hard tubing, as in Figure 6, page 5]. Insert the O-ringed elbow fitting

of the Accuflex hose adapter (sold separately) into the outlet port of the Aquajet pump. Lock fitting in place by

pushing down retainer.

8. Connect inlet adapters

a. [If the Aquajet pump is to be directly plumbed to the existing inlet filter/fitting, as in Figures 5 and 6, page 5]. Insert

the O-ringed end of threaded adapter into the pump’s inlet port (look for arrow pointing towards the center of the

pumphead). Lock fitting in place by pushing down retainer slide.

www.remcoindustries.com Page 3