Ulvac G-5DA User manual

Other Ulvac Water Pump manuals

Ulvac

Ulvac G-20DA User manual

Ulvac

Ulvac DOP-80SP User manual

Ulvac

Ulvac TM-2 User manual

Ulvac

Ulvac MBS-053 User manual

Ulvac

Ulvac UTM3400 Series User manual

Ulvac

Ulvac MS120A User manual

Ulvac

Ulvac DOP-120SX User manual

Ulvac

Ulvac DAL-181D User manual

Ulvac

Ulvac GCD-051X User manual

Ulvac

Ulvac DA-121D Series User manual

Ulvac

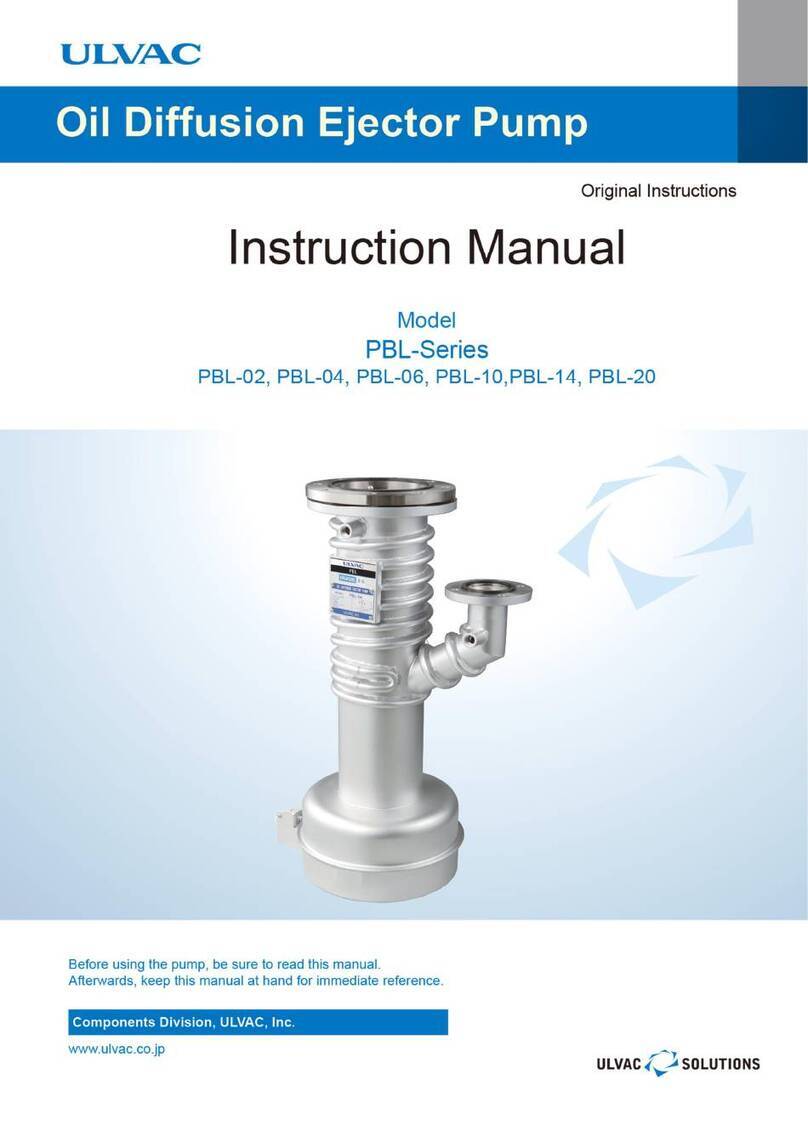

Ulvac PBL Series User manual

Ulvac

Ulvac DAU-100 User manual

Ulvac

Ulvac UTM1600 Series User manual

Ulvac

Ulvac VD30C User manual

Ulvac

Ulvac DA-60D User manual

Ulvac

Ulvac DTC-41 User manual

Ulvac

Ulvac PVD-180 User manual

Ulvac

Ulvac CRYOPUMP CRYO-U Series User manual

Ulvac

Ulvac DOP-400SB User manual

Ulvac

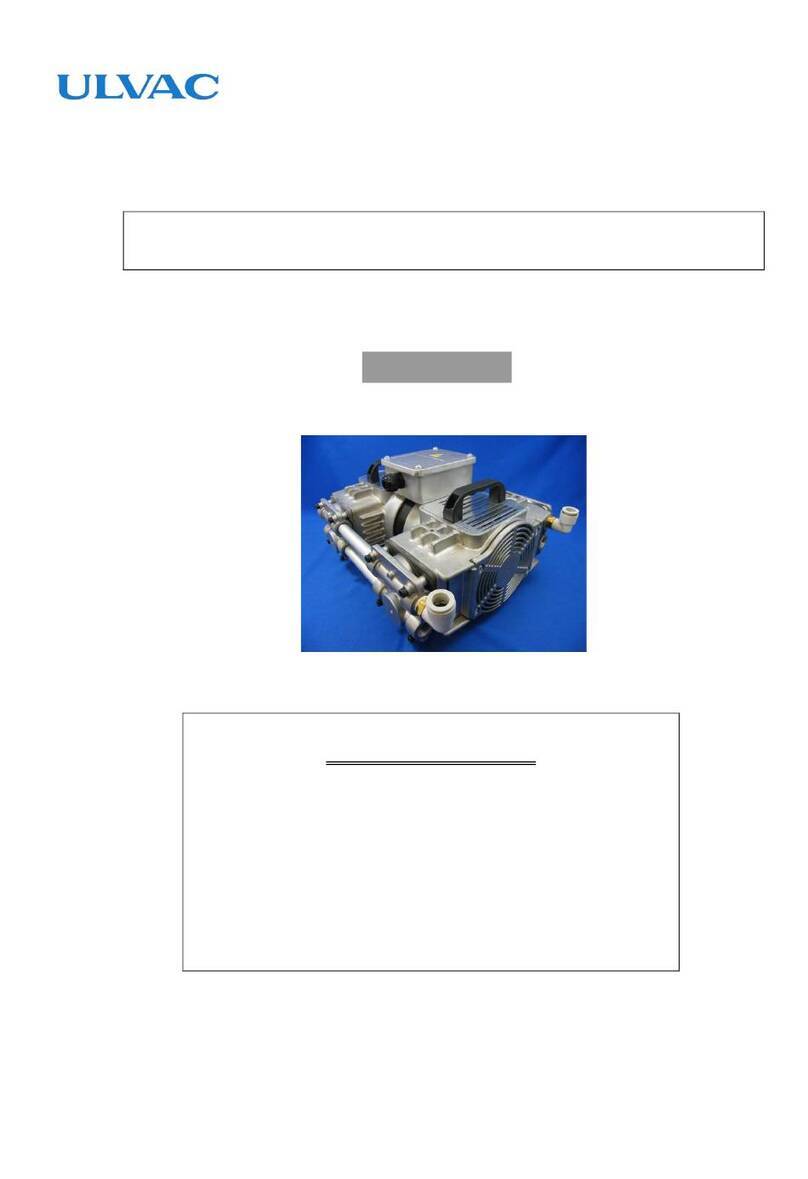

Ulvac DTU-20 Series User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual