790914

BEVERAGE SYSTEM

“B”models contain beverage faucetsonlyand mustbe supplied withcold product fromanyremotecold plate or

refrigerated soda factory.“BC”unitshave a built-incold plate,in addition tothe beverage faucetsand are de-

signed tobesupplied directlyfromsyrup tanks and carbonatorwith no additionalcooling required.

Installation

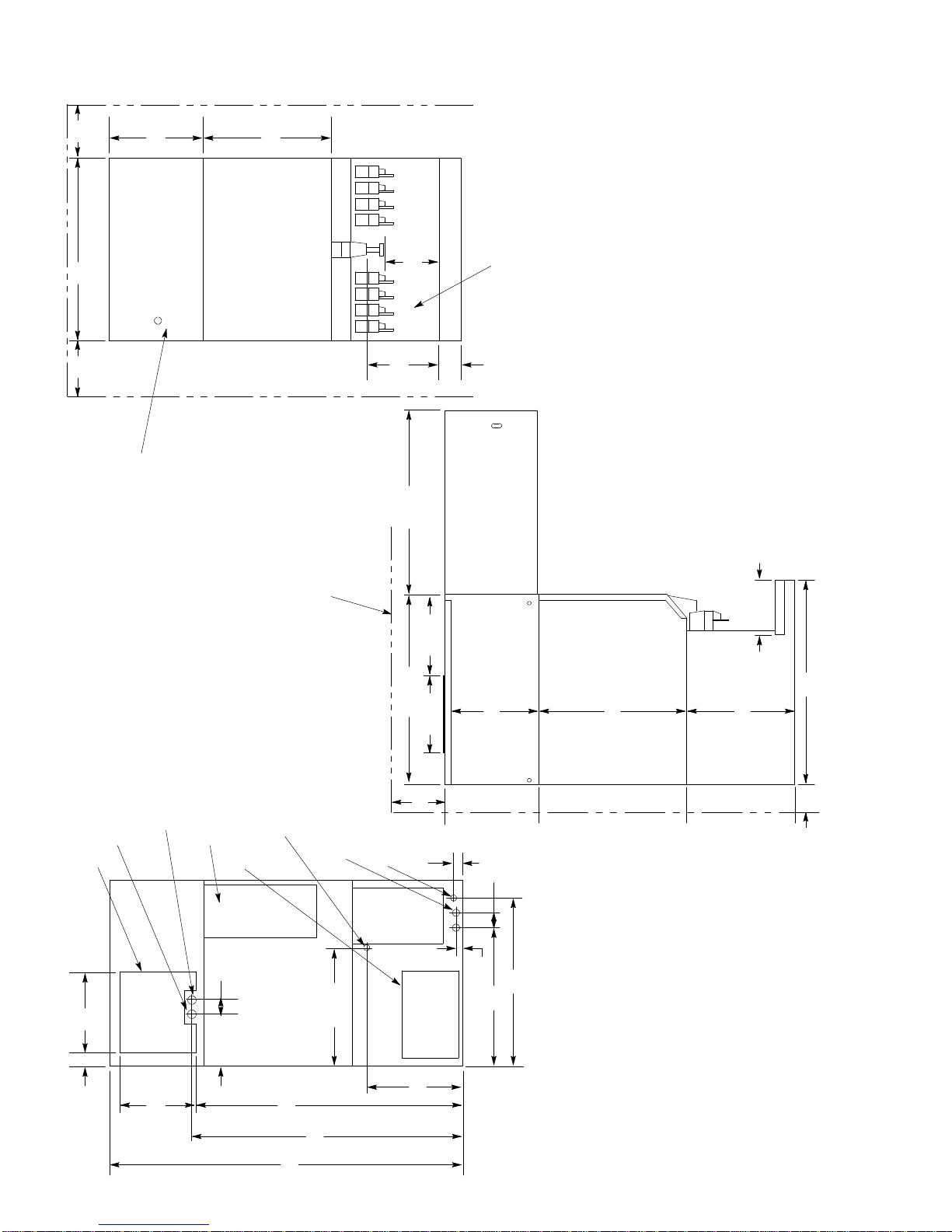

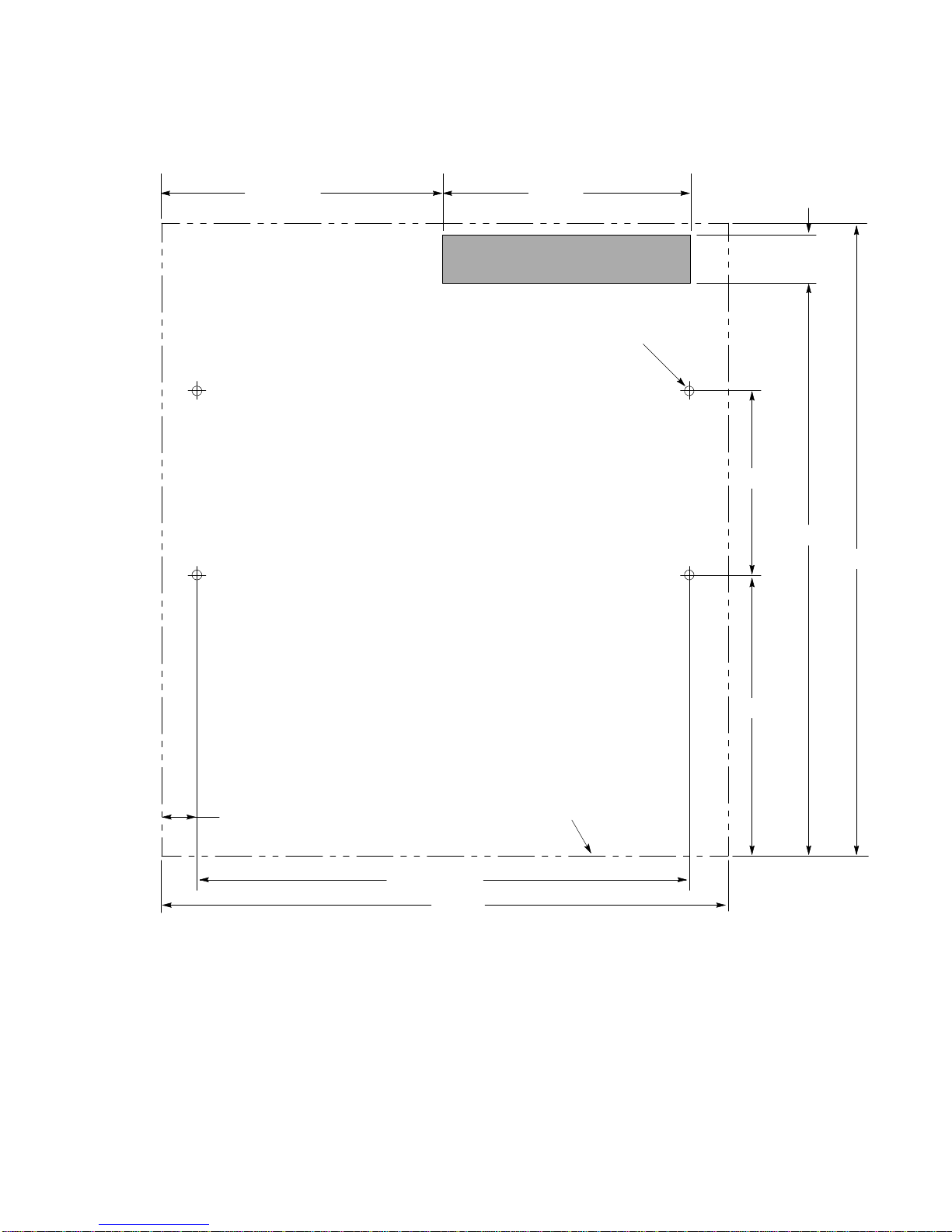

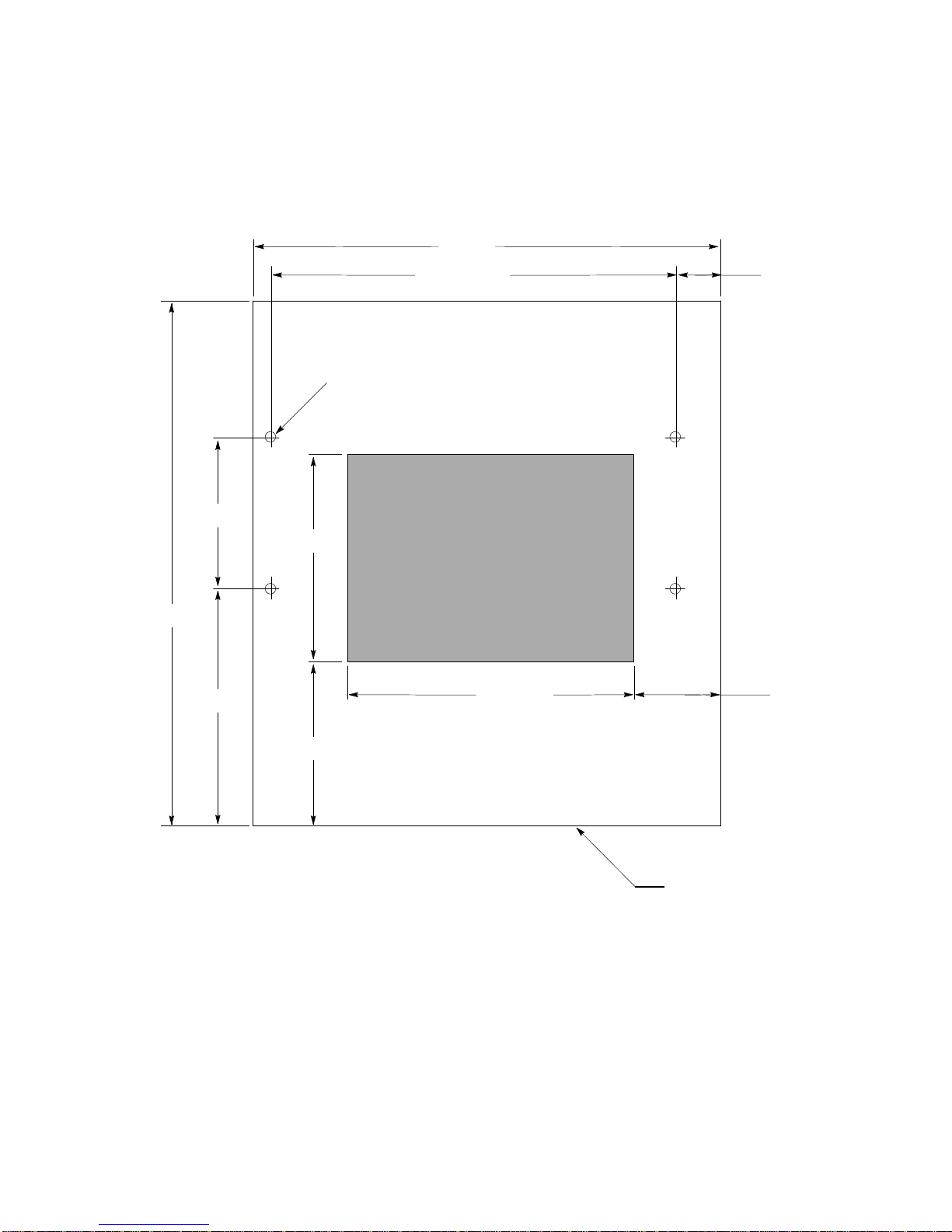

1.Locatethe required openingsinthe countertop forthe beverage linesas showninFigure3(for“B”mod-

els)orFigure4(for“BC”models).

2.For“B”models,carefullypull the beverage tubersthrough the bottomopening inthe unitand through the

clearance opening inthe counter.

3.For“BC”models,1/4? and 3/8? beverage tubing “pigtails”are provided at the frontof the uniton the cold

plateforsyrup and waterline hook-up respectively.

To access theseinlet tubes,removethe lowerfrontpanelabovethe sink.Removethe sinkbydisconnect-

ing the sinkdrainconnection;lifting the two(2)sink side mounting pinsand pulling the sinkforward.

4.Connect the beverage systemproductlinesasindicated inFigure5(“B”units)and Figure6(“BC”units).

Thiswork should be done bya qualified service person.Notethat the hosesaremarked with numbers

(1through 8)forsyrup connection and “CW”forcarbonated waterconnection.

5.For“BC”models,reversethe procedureinstep3toreconnect the sink.Makesurethatall drainconnec-

tionsare properlypositioned beforeinstalling the lowerfrontpanel.

START-UP

1.Open the hinged service door.Removeice drop coverand storage hoppercover.

2.Turnonwatertoicemaker.

3.Depress the flushswitchtoverifythat the waterdumpvalve operatesand that the waterdrainlinesare

open and notplugged.

WARNING:To preventpossibleinjury,do notstick fingersorhand intoice makernozzleor

hopperwith powerappliedto unit.

4.Put the “Stop/Run”switchinthe “run”position.Observethat the icemakergoesthrough propericemaking

and harvestcycles.Ifunitmalfunctions,consult the Troubleshooting Guide.

NOTE:Duetomeltageloss because ofawarmstoragehopper, itwill take longertofill thehopperthe

first timethanwhentheice makerhas been operating continuously.

5.Depress the vend switchlever.Check thatboththe gatesolenoid and agitatormotorare energized simulta-

neouslytolift the gateslide and rotatethe agitatorinthe storage hopper,respectively.Ifeithercomponent

malfunctions,consult the Troubleshooting Guide.Replacethe ice drop and hoppercovers.

6.Forbeverage units,startup the beverage systemand adjust the faucetstothe properbrix.Contactyour

localsyrup distributorforcompleteinformation on the beverage system.Forunitswith a builtincold plate,

itwill take approximatelyone (1)hourfromthe initialmachine start-up forthe cold plateto be at full capac-

ity.

7.The binthermostatis calibrated atan atmosphericpressure equivalentat500 feetabovesea level.For

locationsathigherelevations,itmaybe necessarytore-adjust thesecontrols.Consult the Maintenance/

AdjustmentProcedures section.