REMET CNC TECHNOLOGY SP. Z O.O.

Page 2 of 51

Manufacturer of machinery and equipment, machining

Table of Contents

1. GENERAL SCHEME ........................................................................................................................... 3

2. PURPOSE AND GENERAL DESCRIPTION OF THE APPLIANCE .......................................................... 7

3. SPECIFICATION OF THE DEVICE ....................................................................................................... 8

4. SAFETY GUIDELINES AND INFORMATION ON AN EXISTING RISK MANAGEMENT .......................... 9

General thoughts............................................................................................................................. 9

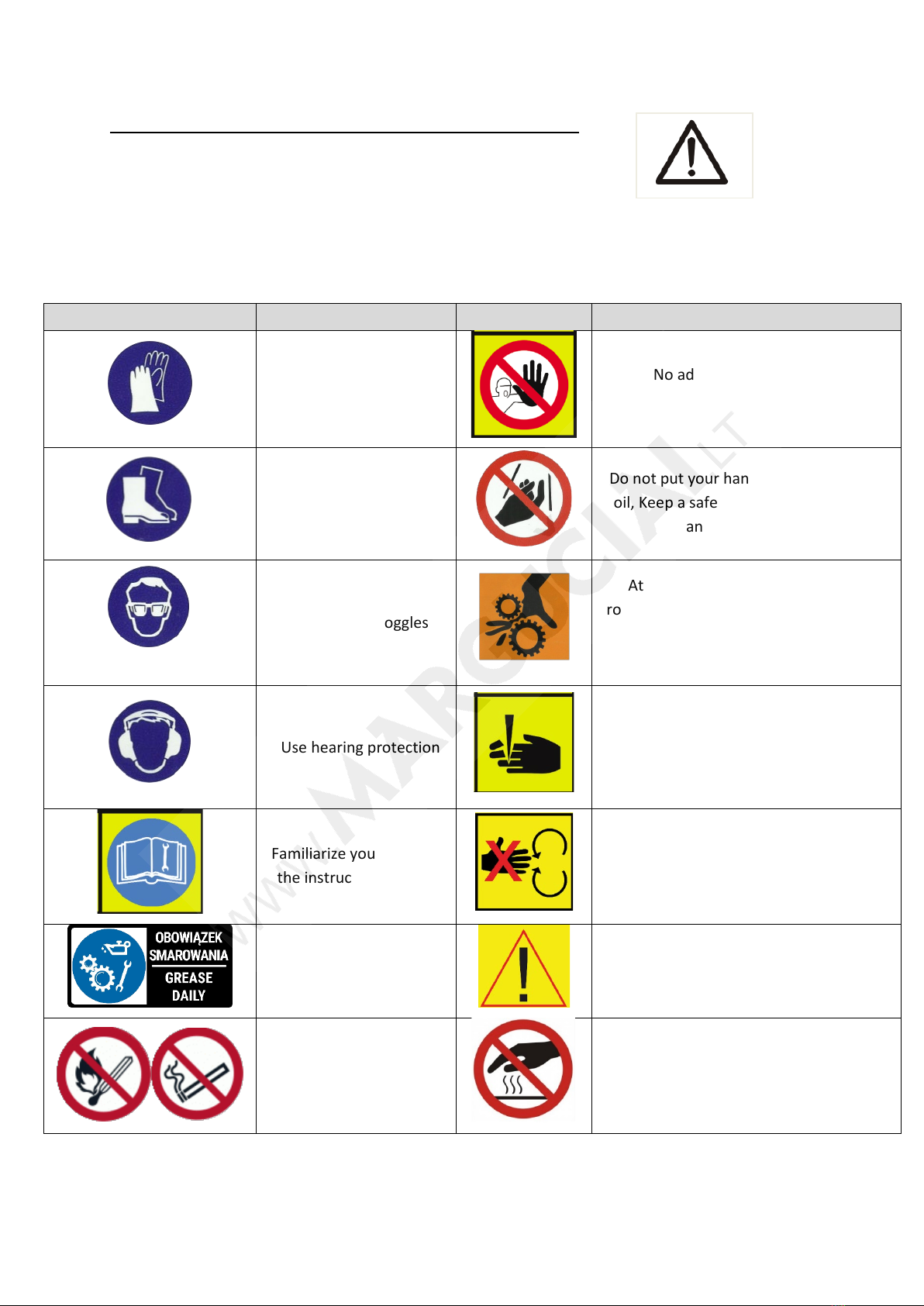

Personal protective equipment and pictograms........................................................................... 10

Saftey switch ................................................................................................................................. 14

Safety notes for internal combustion engine and refueling......................................................... 15

Getting the machine out: .............................................................................................................. 17

Activities after finishing work........................................................................................................ 17

Rules of conduct in emergency situations posing hazards to the life or health of employees..... 18

5. PROHIBITED ACTIONS................................................................................................................... 18

Notes and first aid ......................................................................................................................... 19

6. TRANSPORTATION AND STORAGE OF THE DEVICE ....................................................................... 20

7. MAINTENANCE AND CLEANING .................................................................................................... 20

Safety instructions for maintenance ..................................................................................................... 20

General activities related to maintenance and cleaning............................................................... 20

8. REPLACING AND ALIGINIG THE BLADE AXIS.................................................................................. 21

Setting the axis of cutting knives in RS80, RS100, RS-100 OFF-ROAD........................................... 21

Setting the axis of cutting knives RS-120+PTO, RS-120 OFFROAD ............................................... 22

9. REPLACEMENT PARTS AND ASSEMBLY ......................................................................................... 27

Replacement parts can be ordered directly from the manufacturer. When ordering please

specify the device type and part number. .................................................................................... 27

Spare parts and assembly - model RS-80 ...................................................................................... 27

Spare parts and assembly RS-100 ................................................................................................. 31

Spare parts and assembly RS-120 ................................................................................................. 35

Spare parts and assembly RS-100 OFF-ROAD ............................................................................... 39

Spare parts and assembly RS-100 OFF-ROAD ............................................................................... 43

12. COMBUSTION ENGINE OPERATION .............................................................................................. 48

13. OIL AND AIR FILTER CHANGE......................................................................................................... 49

14. GUARANTEE CARD (based on proof of purchase)......................................................................... 50

PRINCIPLES OF THE WARRANTY GUARANTE:............................................................. 50