MOUNTING SUPPLE TIRES

NEVER RIDE ON A POORLY SEATED TIRE!

• If you cannot get the tire to seat correctly, do not ride the bike! The tire can

blow o the rim, resulting in serious injuries.

• Take your bike to a qualied bike shop, together with these instructions, and

ask for help with installing your tire.

SEAT THE TIRE, IF NECESSARY

• Reduce the pressure to 0.5 bar/8 psi. Lubricate the bead with soapy water.

• Push the tire sidewall upward (below).

• Inate the tire. Repeat these steps until the tire seats.

• Make sure that the molded line is visible all the way around the tire.

Rim compatibility:

• Industry standards (ETRTO) require a G height of

5.5 - 6.5 mm and the correct bead seat diameter

(BSD). Do not use rims that don’t meet ETRTO stan-

dards! More information and rim measurements at

www.renehersecycles.com/rim-and-tire-standards/

• Make sure your rims are not too wide for your

tires. Blow-o risk! For more information, check

www.renehersecycles.com/tech-info/tires/

• Rims labeled ‘For tubeless-type tires only’ are

compatible. (All Rene Herse tires have tubeless-type

beads.) Use with tubes, if your tires are not tubeless-compatible.

Rotational direction: Rene Herse tires can be mounted in either direction.

INSTALLATION

• Start installing the rst bead. Push the bead into the center of the well, all the

way around the rim. Now the bead is slack. Lift the last bit over the rim wall.

• Hard to mount? Check that the bead is in the well – all the way around the

tire – and not caught on the shelf somewhere.

• Inate the tube so it barely holds its shape. Insert it into the tire.

• Lift the second bead over the rim sidewall, starting opposite the valve. Push the

second bead into the center of the well. Deate the tube. Lift the last bit of bead

over the rim wall. Push the valve inward to make sure it is not trapped.

• After mounting the tire, push the tire sidewall inward and check all around the

tire/rim that the tube is not trapped between tire bead and rim.

TUBELESS INSTALLATION

• Only for Rene Herse tires marked tubeless-compatible on the package.

• Do not install tires on undersized rims (see above)! Blow-o risk! If you have

doubts about your rim, install the tire with a tube rst. If the tire seats easily

at low pressure (<40 psi/2.8 bar), the rim’s bead seat diameter (BSD) is likely

too small. Do not use this rim with tubeless tires. Also measure the G height to

make sure it meets ETRTO standards.

• Use enough sealant! Recommended quantity: 26-32 mm wide tires: 60-90 ml

(2-3 oz); 35-44 mm tires: 90-120 ml (3-4 oz); 45+ mm tires: 120-150 ml (4-5 oz).

We recommend SmartSeal. It’s designed to seal supple tires.

• Distribute the sealant all the way around the tire and work it

into every part of the tire/rim interface. Scan the QR code for

detailed instructions for setting up Rene Herse tires tubeless.

• Top up the sealant at least once a month. If the sealant dries

out, the tire can break loose from the rim wall and lose all air.

INFLATE THE TIRE

• Do not exceed the maximum pressures of tire or rim. Use the lower of the two

values. For tubeless installation, do not exceed 4 bar (60 psi). Check the Tire

Pressure Calculator at www.renehersecycles.com for the optimum pressure.

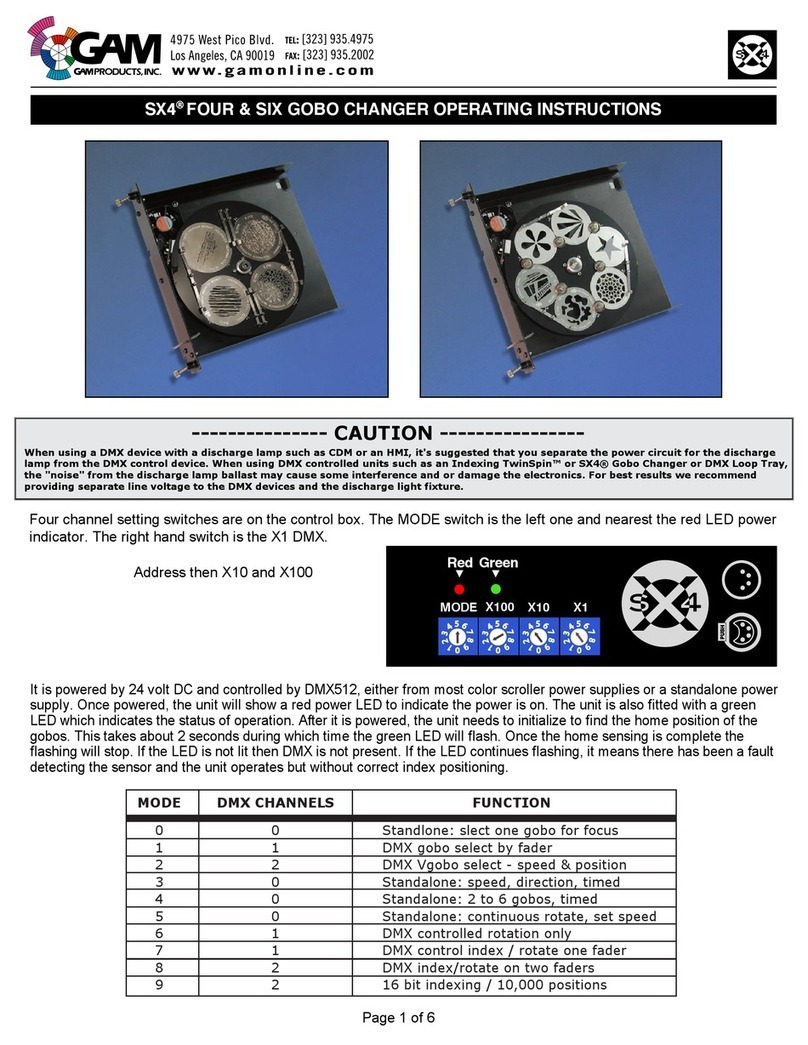

• Tire seating: Check the line that is molded into the tire sidewall (top photo). It

must be even and parallel to the rim edge all around the tire (arrows).

• If the line is uneven or disappears into the rim, the tire is not seated.

Correct Seating

Poor Seating - Do Not Ride!

CHECK: TIRE LINE PARALLEL TO RIM Important!

Rim Cross-Section

Shelf

G height

Well

Shelf

Hook

BSD