UG167 Rev.1.00 Page 9 of 30

Jul 31, 2018

HIP2105-6MBEVAL1Z 2. Functional Description

with the internal inductance of the Li-ion battery (typically a few hundred nH). If the capacitor value is large

enough, the battery voltage is close to the nominal unloaded value with minimal ripple. Another approach to reduce

the amplitude of the voltage transient from the battery without increasing the size or value of the bridge capacitor,

is to increase the PWM switching frequency.

If it is not desirable to use relatively large value capacitors across the bridge, a clamping method must be used to

limit the peak voltage ripple from the battery. In any case, a relatively small capacitor across the bridge should be

used to limit the rate of change of the ripple voltage and to minimize the effects of the PCB parasitic trace

inductance on the Phase pin.

Another consequence of allowing a relatively large ripple voltage on the battery, is that under heavy load

conditions, the voltage ripple valley drops to very low levels. Because most motor loads respond to the average

voltage applied, this ripple voltage is of minimal concern. If the valley voltage drops too low, the UVLO of the

HIP2105/4 is 3.0V typical. If the bridge FETs are selected appropriately, this low-gate drive voltage has no

significant effect except for the usual consequence of higher rDS(ON) of the bridge FETs.

2.9 Setup and Operating Instructions

The following procedures ensure a correct setup of the evaluation board and illustrate various operating methods.

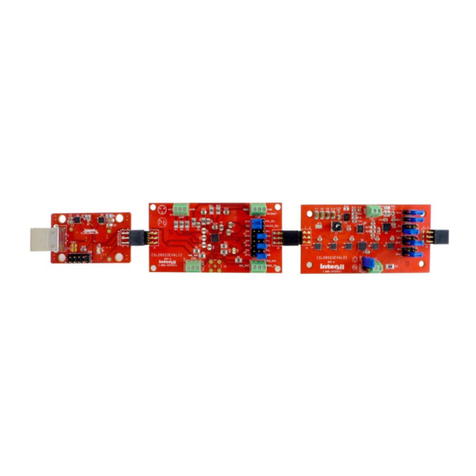

2.9.1 Required Lab Equipment

• Power supply (or battery), 13V minimum to 25V maximum operating for the bridge bias. The current rating of

the power supply must have sufficient capacity for the external load used for testing (if any). If no load is

applied, 200mA is sufficient. If a battery is the power source, it is highly recommended that an appropriate

fuse be used. With a Li-ion battery, it is necessary to add sufficient capacitance (100µF or greater) across the

VBAT terminal block to prevent excessive ringing.

• Bias supply, 5V at ~50mA, required for testing the HIP2105 or HIP2106A

• Bench fan (only necessary when testing with large loads at elevated ambient temperatures)

• Four channel oscilloscope, ~500MHz recommended

• Current probe (optional) when testing with external loads

• Multimeter

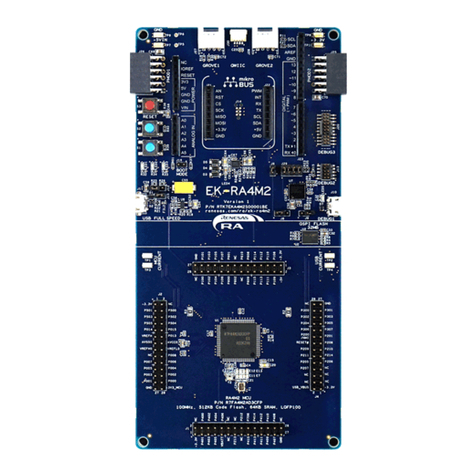

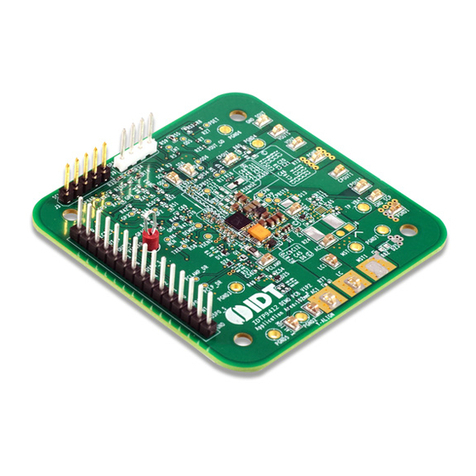

2.9.2 Initial Configuration for the Microcontroller

The following procedure illustrates how to configure the microcontroller without applying power to the bridge.

(1) Connect a 5.0V bias supply to the +5V_GND terminal block (TB8). This voltage powers the

microcontroller.

(2) Ensure that the jumper strap on J2 is on the 5V option. This connects the microcontroller to the external lab

supply.

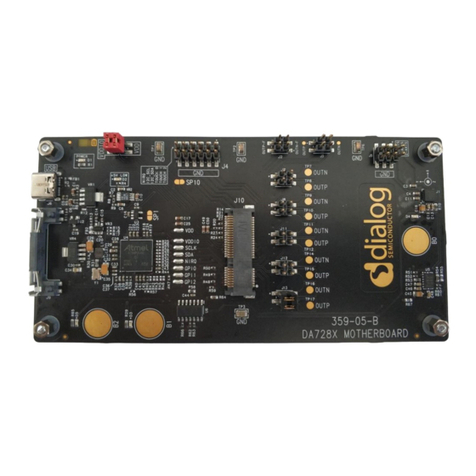

(3) Set up the DIP switch on the mother board with the desired PWM frequency and dead time. For the initial

setup, start with 200kHz and 100ns dead time (in bold type).