i

www.renishaw.com/mp11

Contents

Before you begin ...................................................................1-1

Warranty ...........................................................................1-1

CNC machines ......................................................................1-1

Care of the probe ....................................................................1-1

Patents ............................................................................1-1

Intended use........................................................................1-1

Safety .............................................................................1-2

Information to the user ...........................................................1-2

Information to the machine supplier / installer .........................................1-2

Information to the equipment installer ...............................................1-2

Equipment operation ............................................................1-2

MP11 basics .......................................................................2-1

System operation ....................................................................2-1

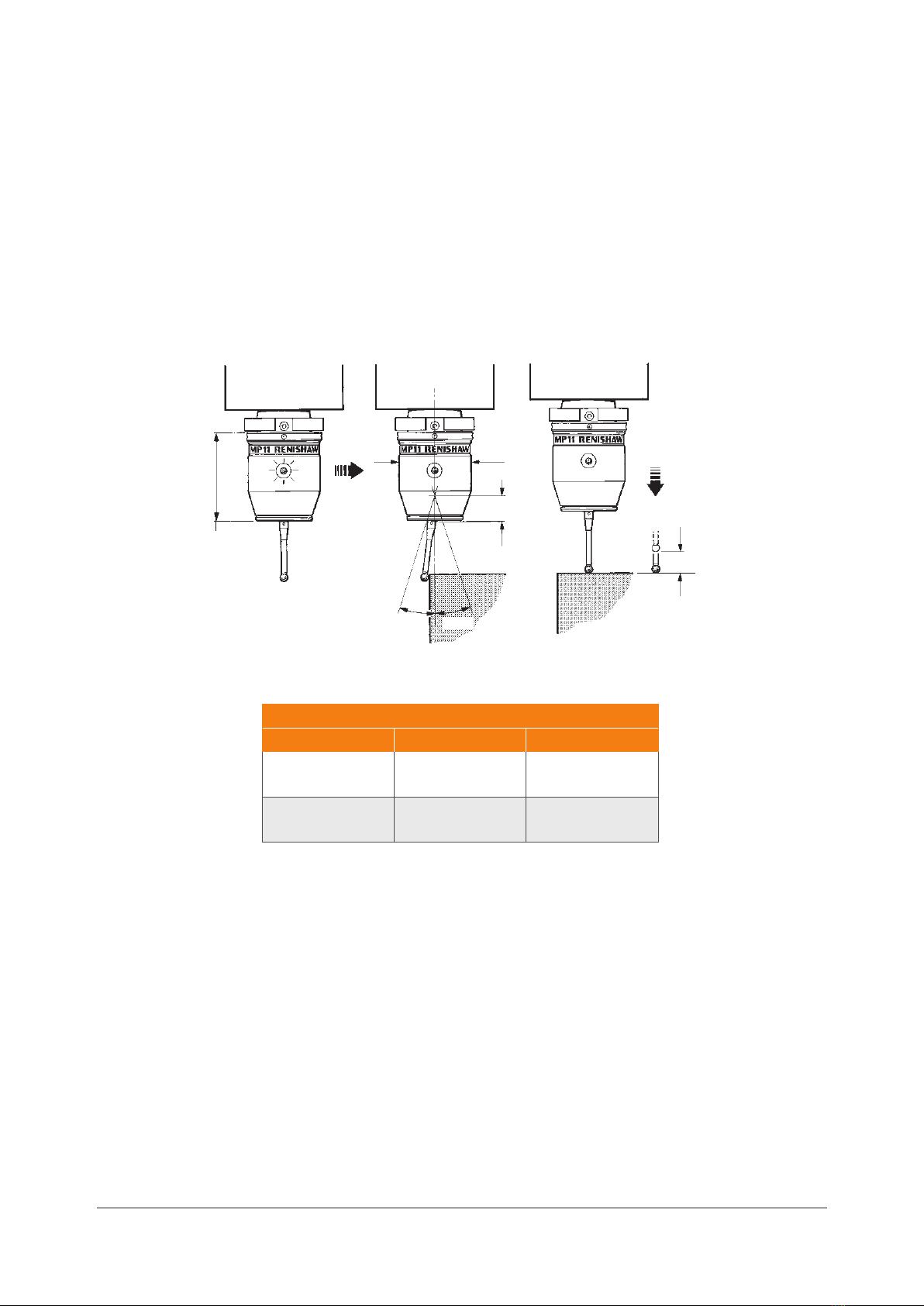

Probe moves .......................................................................2-1

Single and double touch..........................................................2-1

Gauging speed.................................................................2-2

Software requirements ................................................................2-3

Verify your software .............................................................2-3

Job set-up requirements..........................................................2-3

Inspection requirements..........................................................2-3

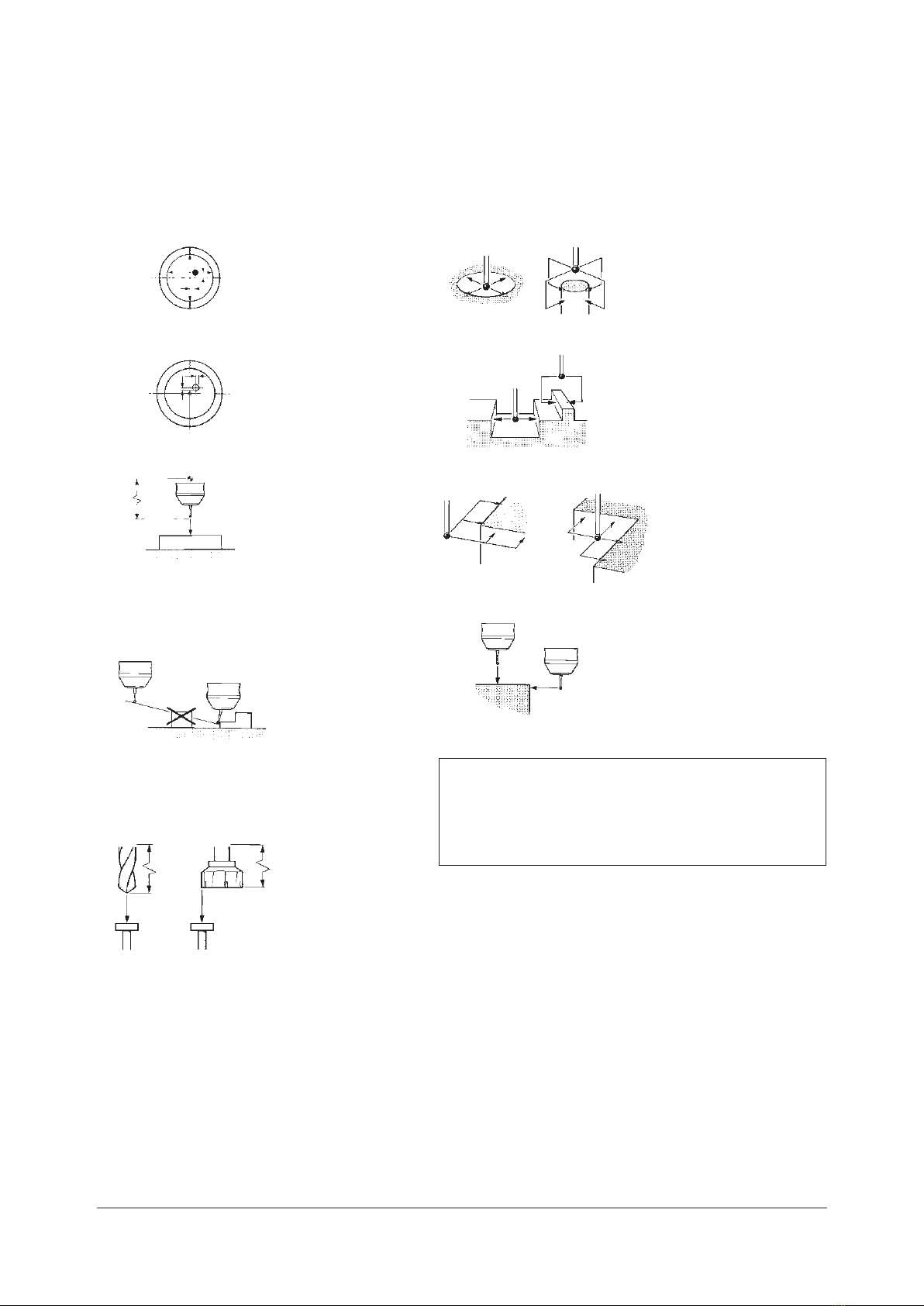

Basic software ......................................................................2-4

Calibration ....................................................................2-4

Protection .....................................................................2-4

Tool setting probe ...............................................................2-4

Inspection.....................................................................2-4

Additional software features ............................................................2-5

Inspection.....................................................................2-5

Inspection.....................................................................2-5

Dimensions.........................................................................2-6

Storage ............................................................................2-6

Specication ........................................................................2-7

System installation..................................................................3-1

MP11 probe system ..................................................................3-1

Shank attachment....................................................................3-2

Stage 1 – attachment ............................................................3-2