2

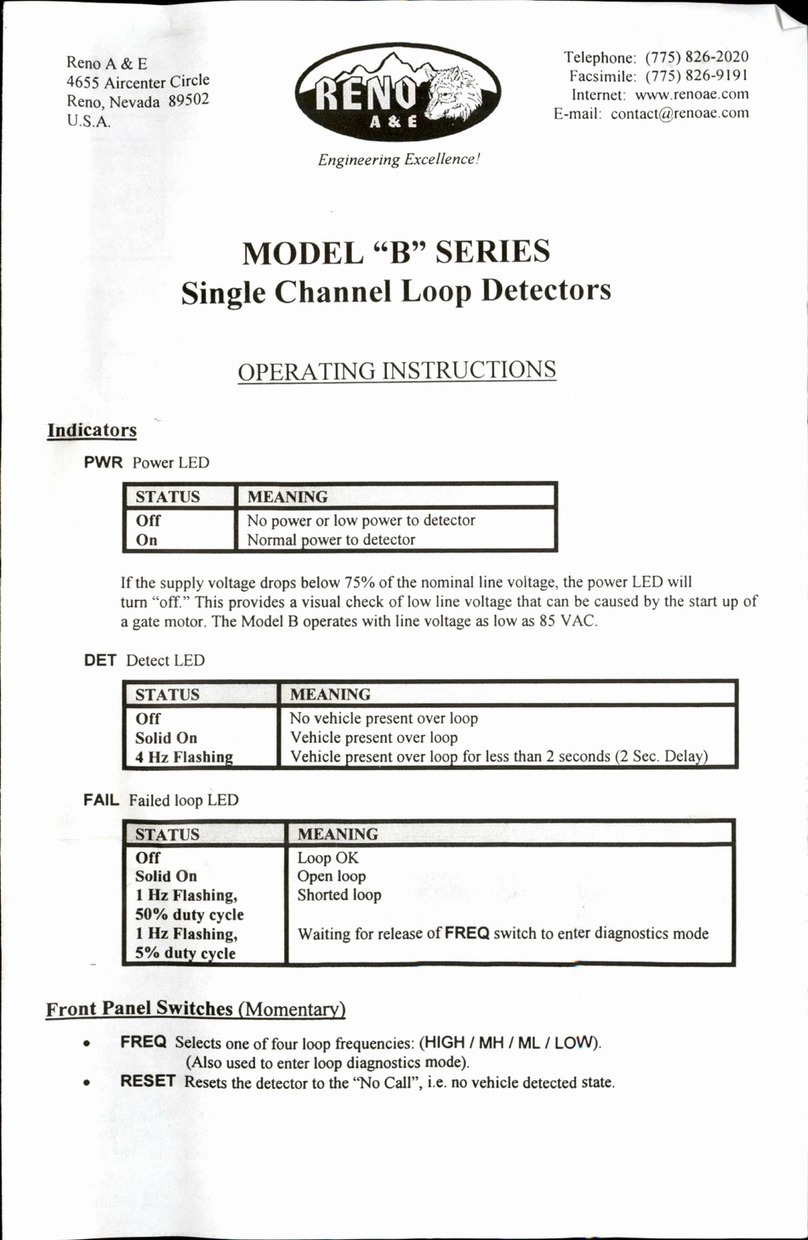

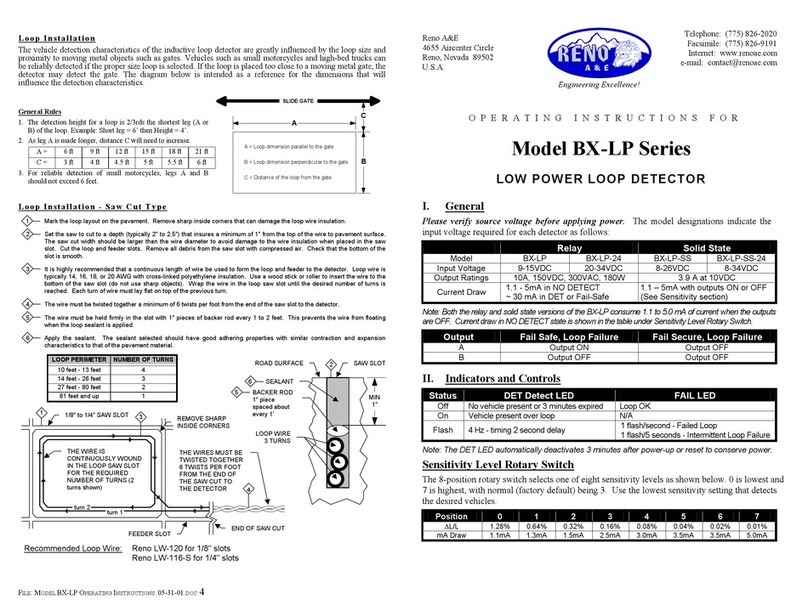

ii Front Panel Rotary Switch (Sensitivity)

The eight-position rotary switch selects one of eight (8) sensitivity levels as shown in the table below. 0 is

lowest and 7 is highest, with normal (factory default) being 3. Use the lowest sensitivity setting that will

consistently detect the smallest vehicle that must be detected. Do not use a sensitivity level higher than necessary.

3.3 mA 3.5 mA 3.8 mA 4.6 mA * 5.0 mA 5.1 mA 5.2mA 7.0 mA

* Factory default setting.

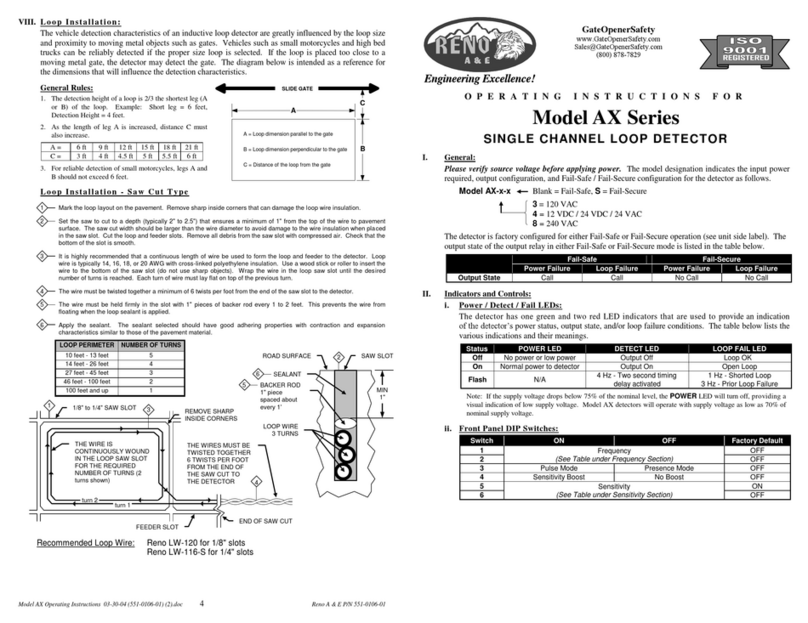

iii Front Panel DIP Switches

Frequency

(See table in Frequency section)

Frequency (DIP Switches 1 and 2)

In situations where loop geometry forces loops to be located in close proximity to one another, it may be necessary

to select different frequencies for each loop to avoid loop interference, commonly known as crosstalk. DIP

switches 1 and 2 can be used to configure the detector to operate at one of four frequencies corresponding to Low,

Medium / Low, Medium / High, and High as shown in the table below.

NOTE: After changing any frequency DIP switch setting(s), the detector must be reset by momentarily changing

one of the other DIP switch positions.

* Factory default setting.

Presence Hold Time (DIP Switch 3)

Output A always functions as a presence output. DIP switch 3 can be used to select one of two presence hold

times; Limited Presence or True PresenceTM. Both modes provide a detect output when a vehicle is present

in the loop detection zone. True PresenceTM is selected when DIP switch 3 is OFF. If DIP switch 3 is ON,

Limited Presence is selected. Limited Presence will typically hold the detect output for one to three hours. True

PresenceTM will hold the detect output as long as the vehicle is present in the loop detection zone provided that

power is not interrupted, and the detector is not reset. TruePresenceTM time applies only for normal size

automobiles and trucks and for normal size loops (approximately 12 ft2to 120 ft2). The factory default setting is

OFF (True PresenceTM Mode).

Sensitivity Boost (DIP Switch 4)

DIP switch 4 can be turned ON to increase sensitivity during the detect period without changing the sensitivity

during the no detect period. The boost feature has the effect of temporarily increasing the sensitivity setting by up

to two levels. When a vehicle enters the loop detection zone, the detector automatically boosts the sensitivity level.

As soon as no vehicle is detected, the detector immediately returns to the original sensitivity level. This feature is

particularly useful in preventing dropouts during the passage of high bed vehicles. The factory default setting is

OFF (no Sensitivity Boost).

Output Delay (DIP Switch 5)

A two second delay of Outputs A and B can be activated by setting DIP switch 5 to the ON position. Output delay

is the time the detector outputs are delayed after a vehicle first enters the loop detection zone. If the two second

Output Delay feature is activated, the outputs will only be turned on after two seconds have passed with a vehicle

continuously present in the loop detection zone. If the vehicle leaves the loop detection zone during the two

second delay interval, detection is aborted and the next vehicle to enter the loop detection zone will initiate a new

full two second delay interval. The detector provides an indication that a vehicle is being detected but that the

outputs are being delayed, by flashing the front panel DET (Detect) LED at a four Hz rate with a 50% duty cycle.

The factory default setting is OFF (no Output Delay).

Fail-Safe / Fail-Secure (DIP Switch 6)

When DIP switch 6 is in the ON position, the detector will operate in Fail-Safe mode when a loop fault condition

exists. If a loop fault condition occurs while Fail-Safe mode is selected, Output A will activate (Relay A Normally

Open contacts closed, Relay A Normally Closed contacts open or Solid State Output A sourced to ground). When

DIP switch 6 is in the OFF position, the detector will operate in Fail-Secure mode when a loop fault condition

exists. If a loop fault condition occurs while Fail-Secure mode is selected, Output A will not activate (Relay A

Normally Open contacts open, Relay A Normally Closed contacts closed or Solid State Output A not sourced to