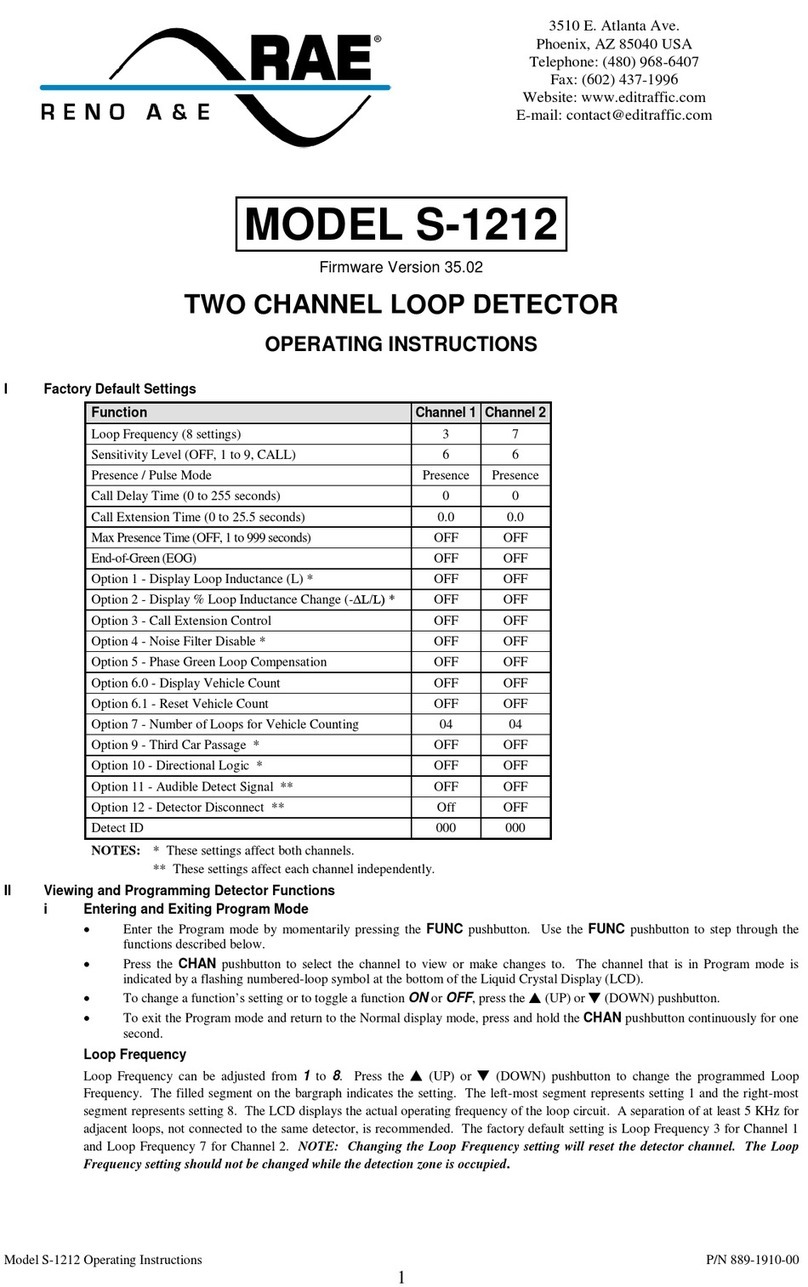

889-2106-03 Model U-1400 Operations Manual Rev Apr 2020 Page 1of 39

Section 1 General Description

This product manual was written for people installing, operating, and maintaining the Reno A&E Model U-1400

inductive loop vehicle detector. The Model U-1400 is a stand-alone, box type, four-channel inductive loop vehicle

detector. It is designed to be used in applications requiring detection of railway vehicles in large detection areas

typically required in classification yard switch and sideswipe protection, interlocking and moveable bridge

occupancy detection, or detection of roadway vehicles and/or railway vehicles in at-grade crossing sites.

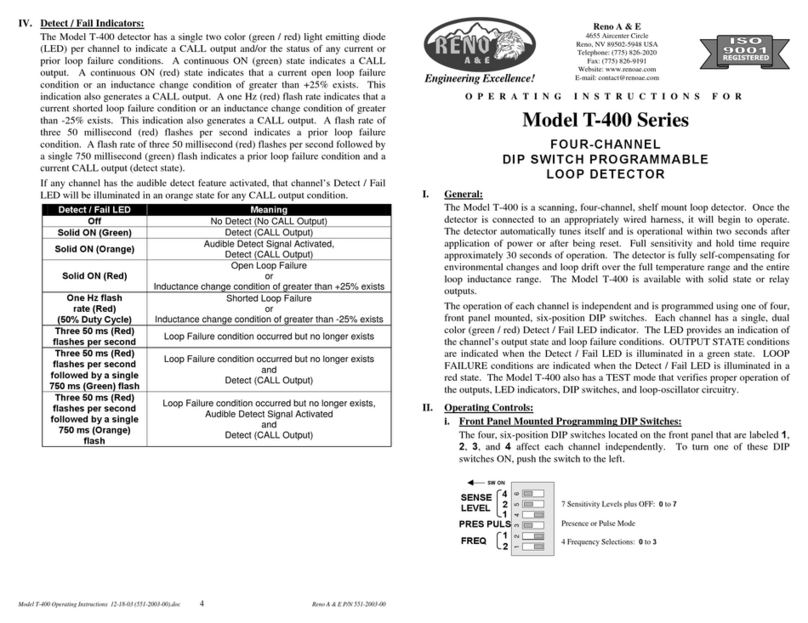

The Model U-1400 monitors and processes signals from four loop / lead-in circuits, four check loop circuits, and

four Vital inputs. These inputs can be programmed to control eight Vital outputs, four primary Vital outputs and

four auxiliary Vital outputs. Each of the four primary Vital outputs can be controlled by any combination of the

four loop inputs and/or any combination of the four Vital inputs. In addition to the four loop inputs and four Vital

inputs (as described above), the four auxiliary Vital outputs can be controlled by the four loop Health Status inputs

that are continuously monitored by the processor. A loop failure will deactivate the Vital output that the loop

status input and/or loop Health Status input is programmed to control. The check loop circuits can be programmed

to simulate a vehicle detection (every 1 to 255 minutes) in the loop area as a means of verifying proper loop

operation. The Vital outputs and Vital inputs are monitored to ensure they are in the correct state. If the state of a

Vital input is not correct, the front panel LED indicator corresponding to that input will turn red and all Vital

outputs will be deactivated. If the state of any Vital output is not correct, the front panel LED corresponding to

that output will turn red and all Vital outputs will be deactivated.

A Liquid Crystal Display (LCD), sixteen LEDs, and four front panel pushbuttons are used to display and program

all detector functions. The Model U-1400 also incorporates a series of front panel mounted connectors to facilitate

set-up and operation. A 55 pin circular connector is used for detector input and output connections, a 15 pin D-

subminiature connector is used to allow connection of an external EEPROM memory module, and a nine pin RS-

232 connector is used for communication with a laptop computer.

The use of a LCD is one feature that distinguishes this detector from that of other manufacturers. It allows for

more information, never before available, to be displayed to the user during normal operation of the detector.

Several diagnostic modes are available to aid the technician in troubleshooting detection problems. It also allows

easy viewing and setting of all programmable values in the detector. The detector continues to operate normally

while being programmed. An eight-segment bargraph at the top of the LCD provides a graphical representation of

the relative change of inductance as seen by the detector. This automatically takes into account loop size, loop

inductance, number of loops, number of turns, geometry, lead-in length, etc. The first bargraph segment represents

the minimum inductance change necessary for the detector to output a call. Larger inductance changes will be

indicated by more segments. Each additional segment represents the next sensitivity level exceeded. Therefore,

the bargraph indicates if the sensitivity is set too high or too low, easily facilitating the ideal setting of sensitivity

level.

All programmed settings are stored in non-volatile memory and can only be changed by programming new

settings. Memory storage consists of an internal EEPROM and an external EEPROM memory module. Settings

programmed on either component must match those programmed on the other for the detector to operate. Loss of

power or a detector reset will not change the programmed settings. If a loop failure occurs, the LCD will display

the type of loop failure as L lo (for -25% change or shorted loop conditions) or L hi (for +25% change or open loop

conditions). Each loop failure is counted (up to a maximum of 255 failures) and accumulated in the Loop Failure

Memory. Information on the number of failures since the last detector reset or power interruption is very useful

during analysis of problems due to intermittent loop operation.

The Model U-1400 detector is a scanning detector. The scanning operation sequentially activates the ON and OFF

cycle of each detector channel’s oscillator. Because only one channel’s input loop(s) is (are) active at a given time,

crosstalk between adjacent loops connected to the same scanning detector is minimized. Several Model U-1400

detectors can be linked together via the Synch In and Synch Out lines. This allows loops connected to different

detectors to be scanned in series or parallel. When in Program Mode, the Model U-1400 detector displays the real

time loop frequency reading for each channel. The eight frequency levels can be incremented or decremented to

provide precise frequency settings. This removes the guesswork when changing frequency settings to eliminate

crosstalk. NOTE: Adjacent loops connected to different channels of a non-scanning detector or different scanning

detectors should be set to different frequencies with the maximum separation possible.

The Reno A&E Model U-1400 utilizes the first major innovation in inductive loop detectors since the introduction

of digital detectors. The programming of all of the detector’s parameters with four normally open pushbutton

switches not only simplifies setup by removing binary coded rotary or DIP switches, but also increases the

reliability of the detector by removing the dependence on switch contacts during normal operation. The detailed

descriptions displayed on the LCD eliminate the interpretation of numerous LED flash rates to determine the

detector status.