P.O. Box 1242 • Chico, CA 95927 • (888) 427-3728

™

®

Quick Start Guide: Vehicle Loading

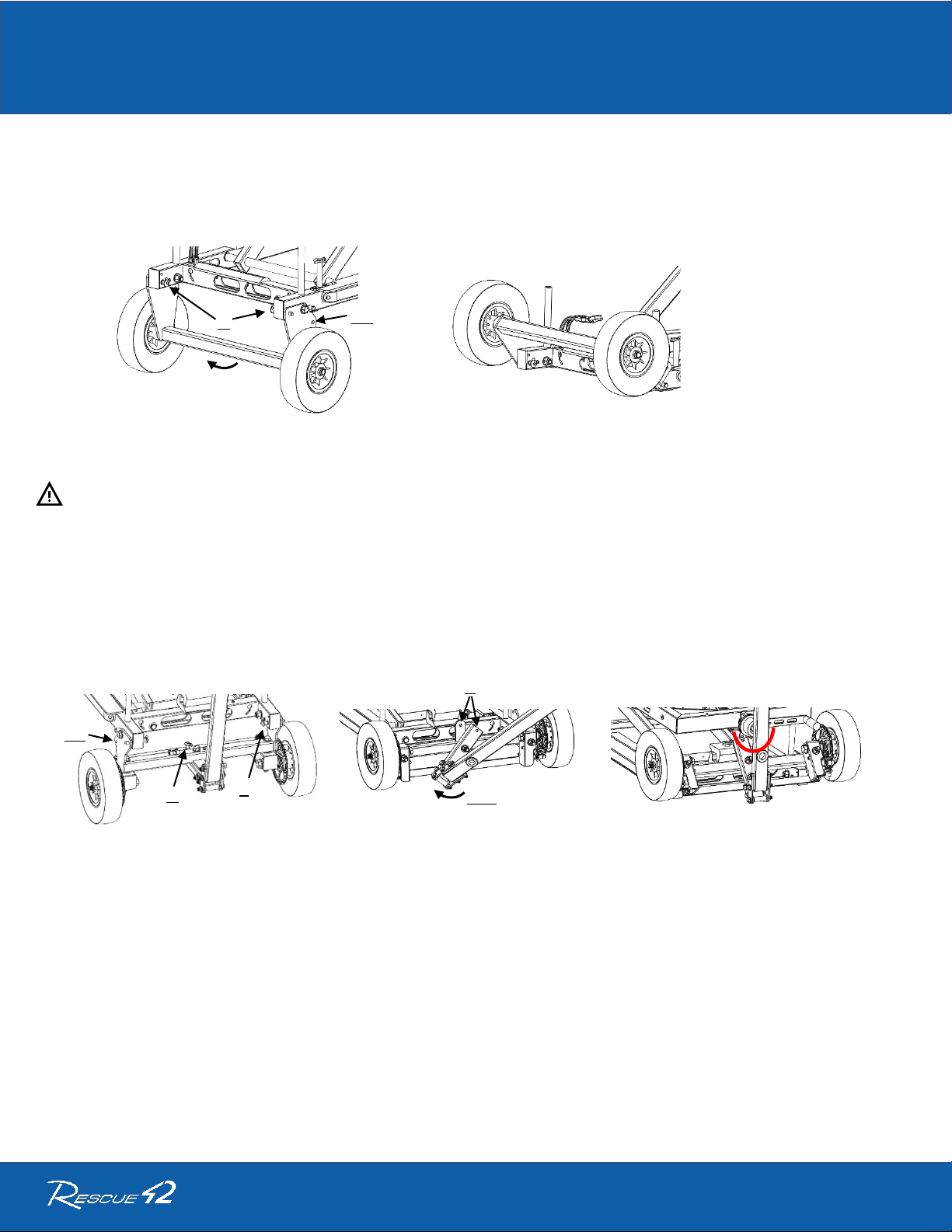

Vehicle Loading

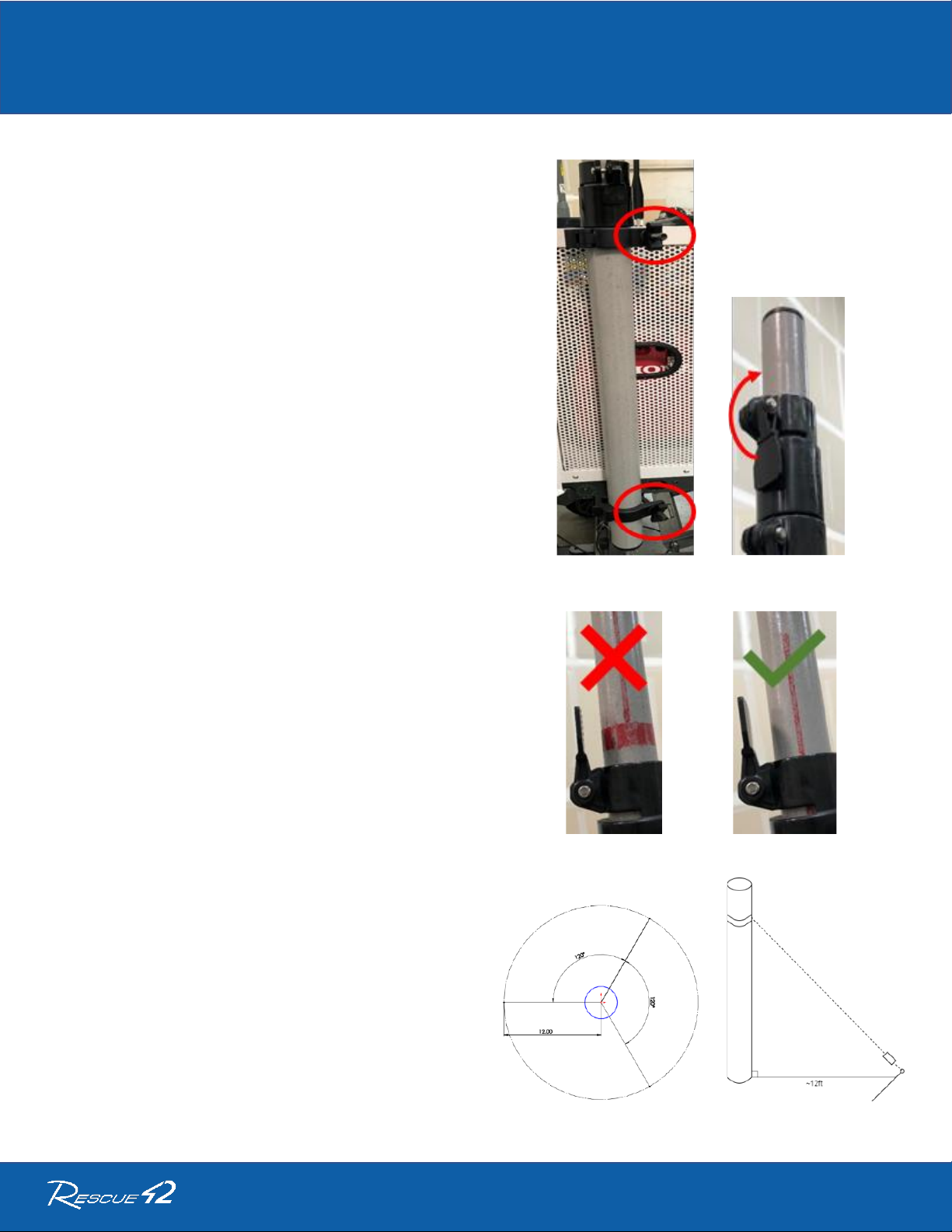

1. Position the vehicle’s tow hitch over solid, level ground.

2. Remove the Hitch Adapter from the Chassis Bed and insert the Receiver Tongue into the

hitch of vehicle. Secure with the Anti-Rattle Hitch Pin ensuring that the threaded block is on

inserted side.

3. Set the Height Adjustment of the Hitch Adapter to highest setting as available based on the

vehicle’s receiver clearance measurement for maximum ground clearance.

4. Pull the Hitch Adapter’s Mounting Box up & away from the vehicle to seat the

PitchLok Pins in the LOAD position.

5. Raise the CRD by rotating the Crank Handle CLOCKWISE to elevate the Mounting

Pin above the Hitch Adapter. Roll into position with the Mounting Pin above the

Mounting Box Receiver Tube.

6. Turn the Crank Handle COUNTER-CLOCKWISE to lower the Mounting Pin into

the Hitch Adapter until the Mounting Tabs drop and lock into their respective holes.

7. Continue lowering until the weight begins to transfer to the vehicle’s suspension.

STOP turning the handle. Give the Unit a firm push towards the vehicle. The

PitchLok Pins will slide down into the TRANSPORT position.

8. Connect the Runner’s Chassis 4-pin connector to the vehicle’s 4-pin receiver and

test for proper operation of the Stop, Turn, and Taillights.

9. After securing the unit into the TRANSPORT Position, continue raising the Lower

Frame until the Mounting Box locks on the tabs of the Lower Frame, then a ¼ to ½

a turn more to add compression securing it to the Hitch Adapter.

Clearance

Measurement