3 USING RPX200 & EPX200

3.1 USE/PRE-CHECK

1. Note! Before use of the equipment always check the function and condition to ensure safe usage. If stored in the Cresto

vacuum solution, only check that the vacuum is still intact. If punctured, you must inspect the function and condition of the

equipment before use.

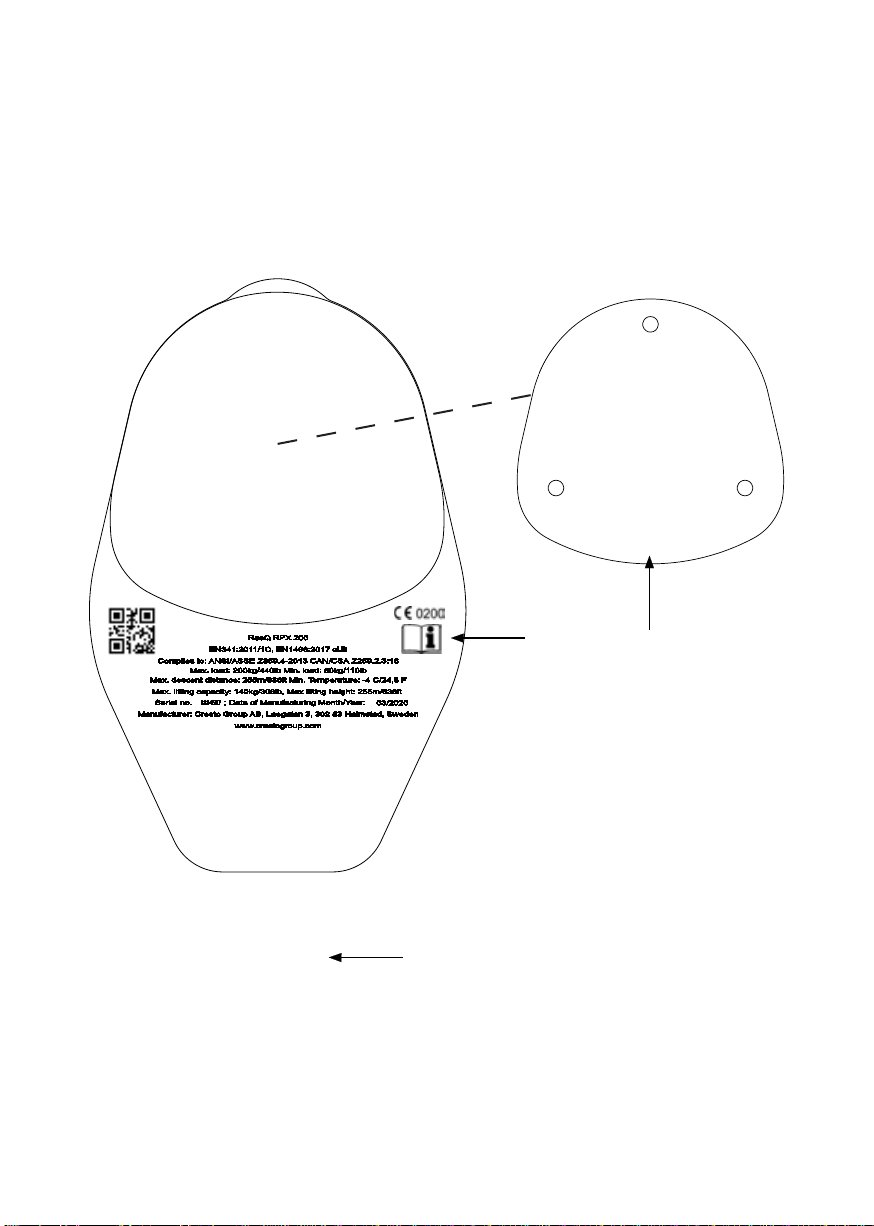

2. Check the legibility of the markings of the device and rope end.

3. Check the rope along its entire length for any signs of chang, varying thickness, cuts, chemical especially acids contact,

change of shape, UV-deterioration, stiffness or other deformation with permanent kinks. Check the stitches in the end

terminations for any loose threads or damage. Check the carabiners in the rope and equipment for any signs of signicant

corrosion, wear, deformation, cracks and limited gate function. Check the descender device for any cracks, deformation or

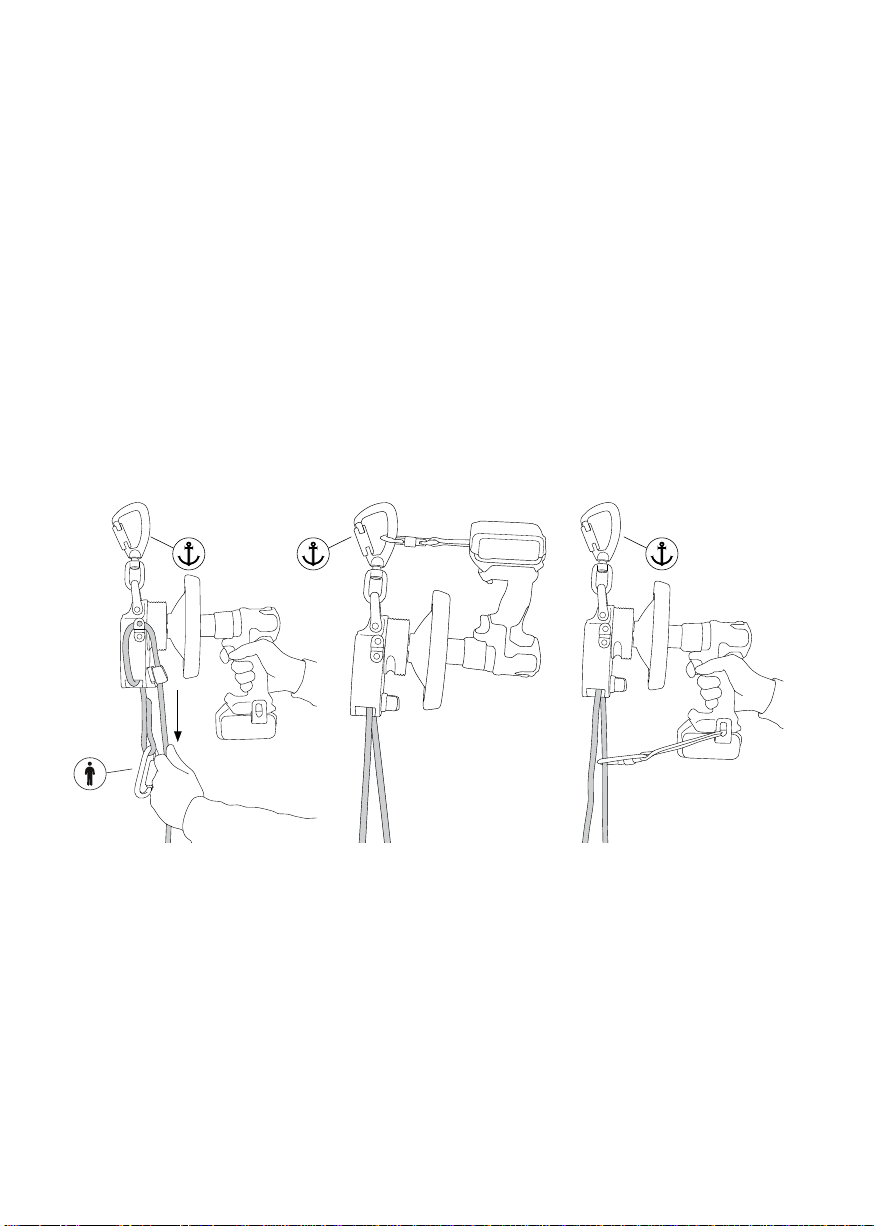

missing parts. While pulling the rope thru the device, check for any “wobble” in the handwheel. Test the brake function of the

device by pulling the rope through the device hard for at least 3m in each direction (Note: that the brake force must increase

with increased pulling power). Check the friction loops for any deformation. Check the function and spring action of the rope

locking mechanism.

Warning! Withdraw the device immediately until conrmed in writing by a competent person if any doubts arise about its condition

for safe use or if it has arrested a fall.

Warning! Always use a fall arrest system if there is a risk for fall when rigging the equipment.

Warning! Always ensure that in a fall-arrest system, it is essential to check for clearance below the user before each use, to avoid

any impact with the ground or an obstacle in case of a fall. Make sure that the anchor point is correctly positioned, to limit the risk

and the height of fall. When using multiple pieces of equipment together, a dangerous situation can arise if the safety function of

one piece of equipment is affected by the safety function of another piece of equipment.

Warning! Extreme temperatures may affect the capacity of the device.

Warning! Protect the rope for any edges that may compromise its integrity.

Warning! Long descent distance with minimum load in high wind and trailing rope may affect the descent speed as the trailing

rope will create a counter force.

Warning! Always have an operator operating the device when top mounted if entanglement of the rope will occur and block the

descent. Last person-/s evacuating will have to body mount the equipment to remain in control.

Warning! During descent the handwheel will spin fast and may cause burn injuries.

Warning! Be careful not to get your hand or ngers inside the handwheel while running. This can cause severe injuries.

Note! Always position the device so that the handwheel doesn’t come in contact with any structure as this can slow down the

descent or result in a complete stop.

Compatible with PPE components within EN, ANSI or CSA designed for the purpose

Note! This must always be in conjunction with the national and local requirements

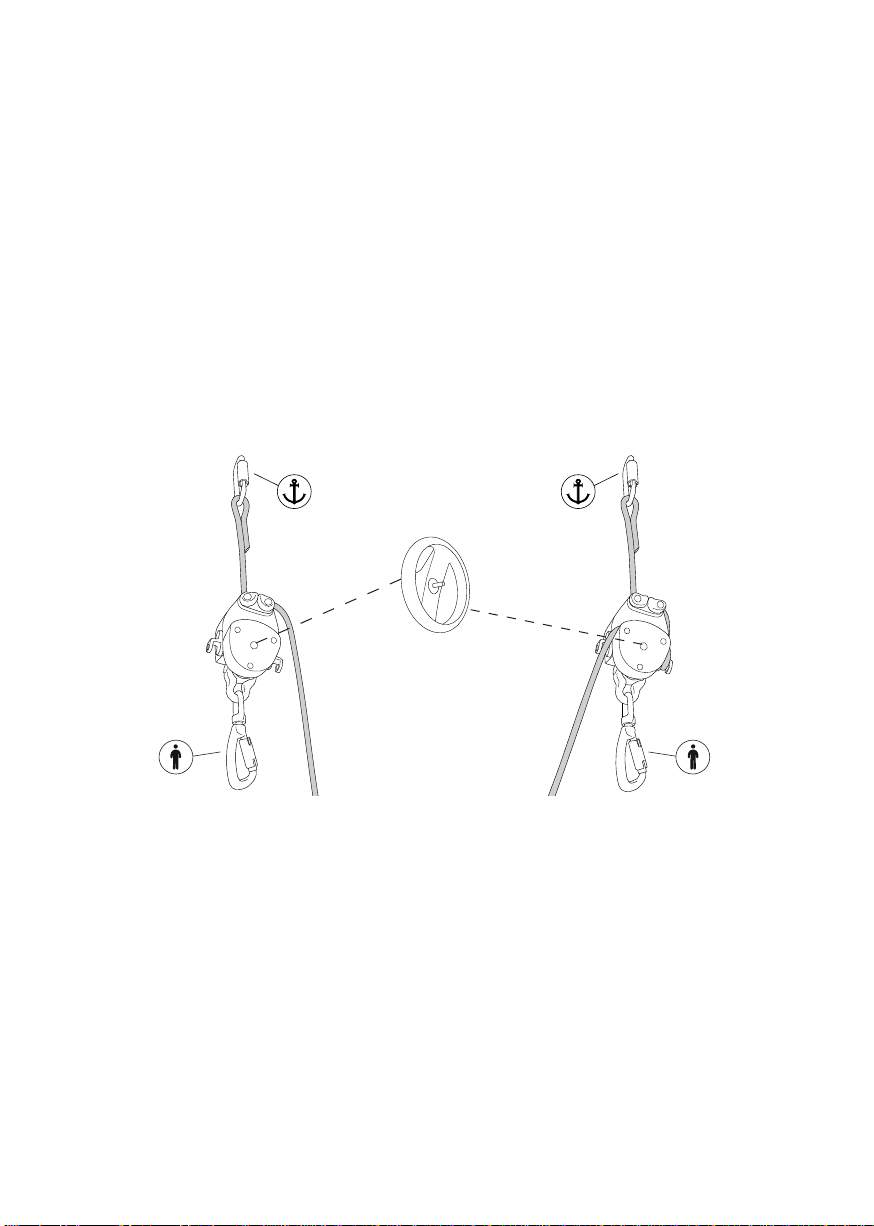

Only connect to a structure with a minimum strength of 12kN or designed for the purpose. Strive to position as high above as

possible and protect from edges that could damage the rope.

To be used with fall arrest harness EN361, Rescue harness EN1497 or rescue slings EN1498.

See user instruction of the body holding device for correct attachment of the equipment.

| v.1 | Master EN | RPX200 & EPX200 |4